7 Must-Know Hydraulic Hose Fitting Safety Tips

Hydraulic hose fitting safety helps stop accidents. It also keeps your workplace safe and working well. If you pick a trusted Hydraulic Product from Novafit, you get parts made for safety. These parts are also reliable. Many accidents happen from bad assembly, high heat, or wear. You can follow safety tips and do regular checks. This can cut emergency repairs by up to 75%. Doing this helps your system last longer. It also saves money. Focus on safety now to stop injuries and damage to equipment.

Hydraulic Safety: Prevent Accidents & Ensure Longevity

- Always let out pressure before you work on hydraulic hoses. This stops dangerous fluid sprays and keeps you safe from harm.

- Wear the right personal protective equipment to stay safe from leaks and sharp edges. This lowers your chance of getting hurt a lot.

- Check hydraulic hoses often to find problems early. This keeps everyone safe and helps your equipment last longer.

- Follow what the manufacturer says for installation and maintenance. This makes sure things work right and helps stop accidents.

- Train your team about hydraulic safety practices. A team that knows what to do can find dangers and stop accidents.

Relieve Pressure

Why Pressure Relief Is Critical

You need to let out pressure before you work on hydraulic hoses. Hydraulic systems hold energy in pressurized fluid. If you do not release the pressure, you could get hurt badly. Parts can move quickly when you disconnect or change them. Toxic fluid might spray out from tiny leaks. Accidents happen a lot when pressure stays in the system.

Tip: Always look at the pressure gauge before you start fixing anything.

Many dangers come from not letting out pressure:

- Hydraulic equipment with pressure is very dangerous.

- Pressure can release fast and cause injury or movement.

- Tiny leaks can spray toxic fluid and hurt people.

- Taking off or changing parts while the machine is on is risky.

- Wrong couplings between low- and high-pressure systems can break things.

Too much pressure can break your equipment. You might lose lubrication, see valve plates come apart, or get mechanical damage. Hoses and seals can fail. One wood plant had pressure spikes up to 3,000 PSI. This caused big shocks and leaks. When they fixed the pressure, the pump lasted longer and the shocks stopped.

Safe Pressure Relief Steps

Follow these steps to let out pressure safely:

- Turn off the hydraulic system and wait for all moving parts to stop.

- Check the pressure gauge to make sure it reads zero.

- Use pressure relief valves to let out any trapped fluid.

- Wear protective gear to keep safe from leaks.

- Look at hoses and fittings for damage before you start working.

Industry standards help you know how to let out pressure safely. Here are some important standards:

| Standard | Description |

|---|---|

| ISO 1436 | Sets rules for rubber hoses and assemblies. |

| ISO 3862 | Focuses on wire-reinforced hoses and burst pressure. |

| SAE J517 | Tells about corrosion resistance and flexibility. |

| SAE J1273 | Gives advice for high-pressure hose assemblies. |

| EN 853 | Covers wire-reinforced hydraulic rubber hoses. |

| EN 856 | Requires checks on spiral wire-reinforced hoses. |

Safety groups also make sure rules are followed. The NHTSA uses SAE standards in federal rules for hydraulic brake hoses. Makers often go beyond these standards to keep you safe.

Note: Always match the hose’s working pressure with your system’s pressure. Use a safety factor of 4:1. Put in pressure relief valves to stop too much pressure.

If you follow these steps and standards, you keep yourself and your equipment safe.

PPE for Hydraulic Hose Safety

Essential Protective Equipment

You need to wear the right gear when working with hydraulic hoses. This equipment keeps you safe from leaks, sharp edges, and things that might fall. Safety groups say you should use different types of protective gear for these jobs. The table below shows what gear you need and why:

| Personal Protective Equipment | Purpose |

|---|---|

| Safety goggles or face shields | Protect against fluid sprays |

| Cut-resistant gloves | Reduce risk when handling heavy or sharp-edged hoses |

| Protective clothing | Includes long sleeves and steel-toed boots |

| Hearing protection | Necessary in high-noise environments |

| Hard hats | Safeguards against falling objects in work areas |

| Safety-toed shoes | Offers protection against heavy equipment |

New gear helps keep you even safer. Some eyewear meets European rules to stop eye injuries. Hard hats with the MIPS Safety System lower head injury risks. Special gloves like the Pirtek Fluid Power Glove can block hydraulic injection. Smart sensors in gear can check your safety while you work. Augmented reality tools show dangers before they happen. New materials make gear more comfortable and last longer.

PPE Best Practices

You should always wear PPE when you handle hydraulic hoses. This habit helps stop many injuries. Here are some injuries you can avoid:

- Hydraulic fluid injection injuries

- Punctures and tears from high-pressure lines

- Burns from hot fluid leaks

- Cuts from sharp hose edges

Check your gear before you start working. Make sure your gloves fit and have no holes. Look at your goggles to see if they have cracks. Wear long sleeves and steel-toed boots to protect your skin and feet. Put on hearing protection if it is loud. Use hard hats where things might fall.

Train your team to use PPE the right way. Teach them how to find damaged gear and change it fast. Remind everyone to follow safety rules. When you use protective gear and good habits, you lower accident risks and keep your workplace safe.

Hydraulic Hose Inspection

Preventive Maintenance Tips

You should make preventive maintenance part of your daily routine. This helps your hydraulic system stay safe and work well. Preventive maintenance lets you find problems before they get worse. Always plan when you will do your inspections. Use a checklist each time you inspect. This helps you remember every important step.

Start by looking at your hoses every day. Check for leaks, cracks, or bulges. Weekly checks help you catch small problems early. Monthly checks let you find bigger issues. Every three months, do a full check of your system. Preventive maintenance keeps your hoses strong and safe.

Here is a table that shows how often to check your hoses:

| Inspection Type | Frequency |

|---|---|

| Daily Visual Checks | Each use |

| Weekly Visual Checks | Weekly |

| Weekly Physical Inspections | Weekly |

| Bi-weekly Physical Inspections | Bi-weekly |

| Monthly Detailed Inspections | Monthly |

| Monthly Physical Inspections | Monthly |

| Quarterly Inspections | Quarterly |

Some industries need special preventive maintenance steps. Oil & gas needs hoses that handle high pressure. Manufacturing needs regular inspection plans. Construction needs hoses that resist extra wear. Always follow the right tips for your industry.

What to Check

You need to know what to look for during maintenance. Good inspections help you find problems early. Here are some tips for checking your hoses:

- Look for damage you can see. Check for cracks, scrapes, or leaks.

- Watch for fluid leaks. If you see fluid pooling, the hose may fail soon.

- Check for bulges or swelling. These signs mean the hose is damaged inside.

- Feel if the hose is stiff. Stiff hoses can crack and break.

- Look at the ends for fraying. Worn ends can cause leaks.

- Notice if your system is slower. If it is, check the hoses.

Use preventive maintenance to keep your hoses safe. Always follow the right tips for your equipment. Regular checks help you stop accidents and keep your workplace safe.

Tip: Write down what you find in your inspections. This helps you see changes and plan future maintenance.

Preventive maintenance is the best way to keep hydraulic hoses safe. You protect your team and your equipment when you follow these steps.

Hydraulic Hose Fitting Installation

Alignment and Tightening

It is important to install hydraulic hose fittings carefully. If you align and tighten them well, you stop leaks and problems. First, make sure the system is safe to work on. Clean the hose ends and fittings. Use a cloth that does not leave lint or use compressed air. Dirt can cause trouble later.

After you know the system is safe, clean the hose ends and fittings. Use a lint-free cloth or compressed air to get rid of dirt. This helps make a safe connection. Check the hose ends and couplings for damage before you keep going.

Pick the right hydraulic hose fitting for your job. Make sure it fits the pressure, temperature, and fluid type. Cut the hose to the right length. This stops stress and problems. Use fittings that match and tighten them well. Put the hose so it does not bend too much or touch rough spots. Test for leaks before you use the system.

Follow these steps to install hydraulic hose fittings safely:

- Always think about safety first.

- Pick the right fittings for your system.

- Tighten fittings the correct way.

- Test and check everything after you finish.

- Fix any problems quickly to keep things working.

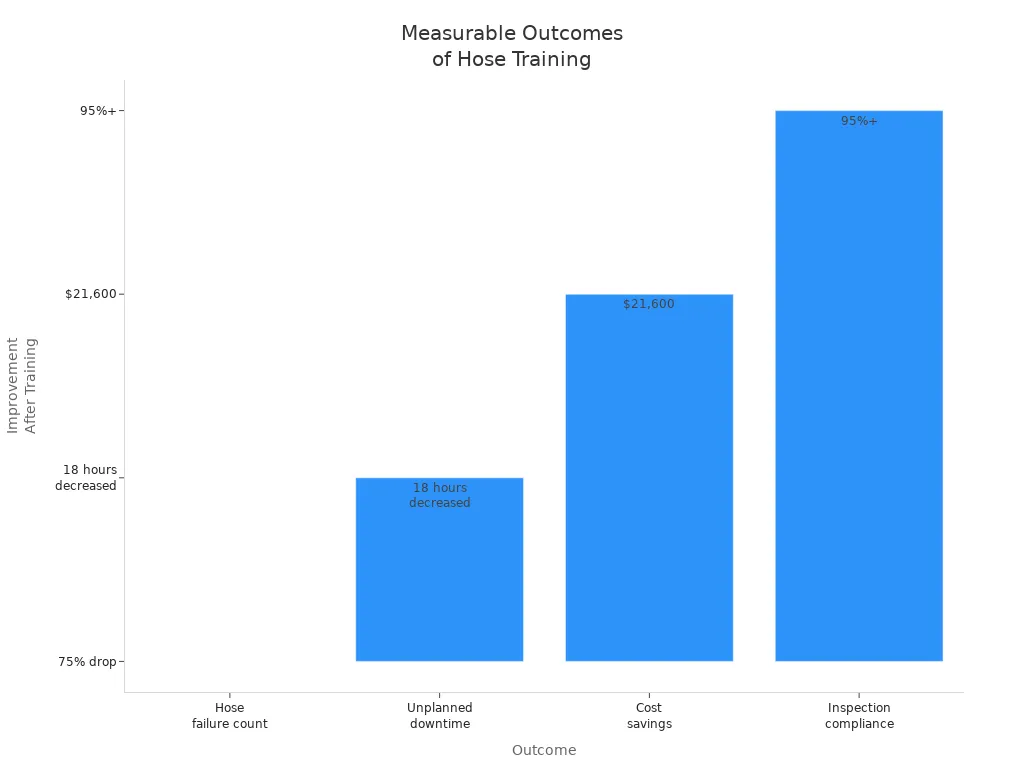

Teach your team how to install hydraulic hose fittings. This helps you have fewer problems and less downtime. The table below shows how training makes things safer and saves money.

| Outcome | Measurement |

|---|---|

| Hose failure count | Went down 75%, from 12 to 3 each year |

| Unplanned downtime | Dropped by 18 hours every year |

| Cost savings | Saved about $21,600 |

| Safety incidents | No hose failures caused injuries |

| Inspection compliance | Went up from 60% to over 95% |

| ROI on training investment | Got results in six months |

Common Mistakes

You can stop many problems if you know the usual mistakes. Using the wrong hydraulic hose fitting or fluid can hurt the hose. This causes leaks and failures. If you route hoses wrong, they can bend or get hot. These things make hoses fail early. If hoses are not tight, they move and wear out fast. If you do not check hoses, you miss damage. This can cause failures when pressure goes up.

Watch out for these mistakes:

- Using the wrong fluid can make hoses fail.

- Routing hoses wrong can bend them and make them hot, which causes failures.

- Not securing hoses lets them move and wear out, leading to failures.

- Not checking hoses lets damage stay, which causes failures when pressure rises.

Check every hydraulic hose fitting before you put it in. Use the right hydraulic fitting for your system. Always look for damage or wear. Good habits help you stop failures and keep your equipment safe.

Hose Safety Covers

Firesleeves and Protective Sleeves

Hydraulic hoses need protection from heat and damage. Firesleeves and protective sleeves help keep hoses safe. Firesleeves started in the 1970s for military planes. They use strong glass fiber and silicone rubber. This helps hoses stay safe from fire and high heat. Novafit sells many hose safety covers made from tough materials. These covers protect hoses in hard jobs.

Firesleeves lower the chance of heat damage. This keeps hoses working well and strong. Protective sleeves stop damage from rubbing and leaks. They help prevent hoses from breaking suddenly. This keeps your workplace safe. Some sleeves are made from textile or nylon. These sleeves last long and help stop oil leaks.

Firesleeves and protective sleeves help hoses last longer. They also help stop expensive problems. Using the right hose safety covers keeps your team and equipment safe.

Here is a table that shows why hose safety covers are important:

| Feature | Description |

|---|---|

| Enhanced Safety | Lowers hose failure and fire risks. Protects people and equipment. |

| Extended Hose Life | Stops damage from rubbing and heat. Saves money on repairs. |

| Durable Construction | Made from strong materials for tough work. |

| Applications | Shields hoses from heat and sparks. Lowers risk of sudden hose breaks. |

| Improved Safety | Keeps workers safe and helps stop downtime in important jobs. |

Installation Guidelines

Pick the right hose safety cover for your job. Think about the heat, pressure, and fluid type. Make sure the cover fits your hose and fittings. Novafit can help you choose the best cover.

Follow these steps to put on hose safety covers:

- Use sleeves to keep hoses away from rough spots.

- Make sure the cover fits well but does not squeeze the hose.

- Check that the cover can handle your system’s heat and pressure.

- Use covers that hold fluid if a hose leaks or bursts.

- Look at covers often for damage or wear.

Hose safety covers help stop leaks and hose breaks. They protect hoses from outside harm and keep fluid inside if a hose fails. Some covers, like Gates’ LifeGuard sleeve, use two nylon layers. These layers soak up energy from leaks and hold pressurized fluid. Textile sleeves also help stop oil leaks.

Here is a table to help you pick the right hose safety cover:

| Criteria | Description |

|---|---|

| Temperature | Make sure the cover works with your system’s heat. |

| Application Compatibility | Check rules for your job and area. |

| Medium | Use covers that match the fluid in your hose. |

| Pressure Rating | Pick covers that handle your system’s pressure. |

| Ends | Use fittings that fit your hose and cover. |

| Supplier Reputation and Support | Choose a trusted supplier like Novafit for good quality and help. |

Tip: Always check hose safety covers when you do maintenance. Change damaged covers fast to keep your system safe.

Hose safety covers help stop leaks, protect hoses, and keep your workplace safe.

Follow Manufacturer Safety Guidelines

Using SAE J 1273-2021

You must follow safety rules when working with hydraulic hose fittings. SAE J 1273-2021 gives easy steps for safe installation and care. These steps help stop accidents and keep your equipment working well.

Here is a simple list of what SAE J 1273-2021 says:

- Look at the hose before you put it in. Check the length, routing, and fittings for any damage.

- Be gentle with the hose. Do not bend it too much or make sharp kinks.

- Use a torque wrench to tighten fittings. This helps keep pressure seals strong.

- Test the system after you install the hose. Check for leaks and get rid of trapped air.

- Check hoses and fittings often. Watch for leaks, damage, or wear.

- Store hoses the right way. Keep them cool and dry. Make sure you control how old they are.

You should also check other safety rules like DIN 2353, ISO 8434-1, and BS EN ISO 12151-2. These rules help you pick the right size, material, and type of fitting. They help your system stay safe and work well.

Tip: Always use the right tools and safety gear. Wear gloves and safety glasses when you install or check hydraulic hoses.

Novafit Support

Novafit helps you follow safety rules with certified products and expert help. Novafit has ISO 9001, ISO 14001, and CE certifications. These mean Novafit checks the quality and tests every product. You get fittings that last longer and work better.

Certified suppliers like Novafit test and check every fitting. This lowers the chance of leaks and failures. You avoid costly downtime and keep your workplace safe. Novafit’s support team helps you pick the right products and gives tips for safe installation. You can ask for help with fixing problems or maintenance.

Here is a table with common manufacturer safety rules:

| Safety Tip | Why It Matters |

|---|---|

| Proper Sizing | Stops hose failure |

| Material Selection | Prevents brittleness and corrosion |

| Bend Radius | Lowers fatigue at fittings |

Always follow the manufacturer’s instructions. This keeps your hydraulic system safe and helps you avoid expensive problems.

Training for Hydraulic Hose Safety

Safety Education

You need good training to keep your hydraulic system safe. Training helps you find problems before they get worse. You learn to spot warning signs like odd noises or leaks. You also notice sudden pressure changes or strange machine moves. When you know what to watch for, you can stop accidents early.

Try different ways to learn new skills. Here are some good ways to train:

- Learn from trainers who know the safety rules.

- Practice with real hydraulic parts to get better.

- Go to safety meetings and toolbox talks often.

- Study how to use hoses and fittings the right way.

- Teach maintenance teams to check and install hoses.

Keep learning so you stay up to date. You will get better with new tools and rules. The table below shows how each training type helps you work safely:

| Training Approach | Description |

|---|---|

| Comprehensive Training Programs | Teaches about hose whip dangers and safe handling. |

| Hands-On Training | Lets you practice spotting hazards and using safe techniques. |

| Ongoing Education | Gives you updates on the latest safety practices and technology. |

Building a Safety Culture

You help build a safe workplace when you share what you learn. You show others how to be safe by setting a good example. Remind your team to check the hydraulic system often. Talk about safety in meetings and ask questions.

A strong safety culture gives you many good things:

- You keep workers safe from bad injuries.

- You help the hydraulic system last longer and avoid downtime.

- You lower the chance of losing money or getting in trouble.

When everyone cares about safety, work is better for all. You feel sure using the hydraulic system, and your team supports you. Make training and safety talks part of your job every week. This keeps your hydraulic system strong and your team safe.

You make your workplace safer by using these seven safety tips daily. Workers should check hydraulic hoses often. They need to wear the right gear. Always follow the rules from the manufacturer. Learn new safety standards to keep up to date. Track how long each hose is used. Test hoses for leaks to find problems early. Workers must learn how to connect and disconnect hydraulic hoses. Plan regular checks to stop hose failures. Keep good records of all inspections. Novafit gives certified products and support to help you avoid accidents. Look at your hydraulic hoses and improve your safety steps now.

FAQ

What are the most common hazards when working with hydraulic hoses?

You can get hurt by fluid injection or burns. Hoses can burst and cause injuries. Sharp hose edges and leaks are dangerous. Always follow safety steps and use safety products to stay safe.

How do hose sleeves improve operator safety?

Hose sleeves protect you from heat and leaks. They help stop sudden bursts. You are less likely to get hurt. Pick sleeves that fit your system for better safety.

What steps help prevent hydraulic hose failure?

Check hoses often and change damaged ones. Use safety steps and put on safety products. Firesleeves and covers help stop problems. Regular checks help you avoid downtime and keep things working.

Why is preventive maintenance important for hose safety?

Preventive maintenance helps you find problems early. You can avoid getting hurt and lower hose failures. Maintenance helps stop downtime and keeps equipment safe. Write down what you find to plan repairs.

How do I select the right hose safety products for my application?

Look at your system’s pressure, temperature, and fluid type. Use a table to compare safety products. Ask Novafit if you need help. The right products protect hoses and lower injury risks.

Tip: Always use certified hose safety products. They help protect your team and keep everyone safe.