How to Choose Reliable Hose Fitting Suppliers for Heavy Machinery

When you select a hose fitting supplier for heavy machinery, you protect your operations from unexpected downtime. Reliable suppliers help you maintain equipment performance, support preventive maintenance, and improve workplace safety. You need to prioritize quality, compliance, and responsive service to avoid costly disruptions in industries like construction, mining, and agriculture. Strong supplier partnerships keep your machinery running efficiently and help you meet demanding project schedules.

Hydraulic Fittings Supplier Selection Guide

- Prioritize supplier certifications like ISO 9001 and IATF 16949 to ensure quality and compliance in hydraulic fittings.

- Choose hydraulic fittings that meet industry standards to enhance safety and performance in heavy machinery.

- Evaluate supplier reputation through customer reviews and industry experience to ensure reliable service and support.

- Confirm supply chain reliability by checking delivery options and customization capabilities to avoid project delays.

- Request product samples to verify quality and compatibility before making large-scale purchases.

Key Criteria for Hose Fitting Supplier

Supplier Qualifications & Certifications

When you evaluate a hose fitting supplier for heavy machinery, certifications should be your first checkpoint. Recognized certifications signal that suppliers follow strict international standards and best practices. Look for these key certifications:

- ISO 9001: This standard shows that the supplier has a strong quality management system.

- IATF 16949: This certification is vital for automotive and heavy equipment applications. It focuses on preventing defects and reducing quality fluctuations in the supply chain.

- ISO 14001: This standard demonstrates a commitment to environmental management and sustainability.

- ISO 45001: This certification covers occupational health and safety management.

You should also check for industry-specific certifications like SAE and CE, which ensure that hydraulic fittings meet safety and performance requirements for high-pressure applications. Suppliers like Novafit hold these certifications, which reflect their dedication to reliability and quality.

Tip: Always request up-to-date certification documents from your supplier. This step helps you verify compliance and avoid risks in your supply chain.

The table below shows how different certifications impact reliability and customer satisfaction:

| Certification Type | Implication for Reliability and Satisfaction |

|---|---|

| ISO Certifications (e.g., ISO 9001) | Shows adherence to international quality management standards. |

| Industry-specific certifications | Ensures compliance with regulations and builds customer trust. |

| Environmental and safety certifications | Reflects commitment to sustainability and safety, improving customer perception. |

Hydraulic Fittings Quality Standards

Quality standards for hydraulic fittings play a critical role in the safety and performance of your heavy machinery. You need to ensure that your supplier’s products comply with recognized industry standards. Here are some of the most important ones:

| Standard | Description | Safety Factor |

|---|---|---|

| ISO 1436:2009 | Integrates SAE J517 and EN 853 standards, defining six series of hoses. | 4:1 |

| ISO 3862:2009 | Covers high-pressure spiral-wound hoses for heavy-duty applications. | 4:1 |

| GB/T 3683 | Domestic standard equivalent to ISO 1436:2009. | 4:1 |

| GB/T 10544 | Domestic standard equivalent to ISO 3862:2009. | 4:1 |

| SAE J517 | U.S. standard for hydraulic hoses. | 4:1 |

| EN 853 and EN 856 | European standards for hydraulic hoses. | 4:1 |

When you choose hydraulic hose fittings that meet these standards, you protect your equipment from premature failure. Certified fittings meet benchmarks for pressure, temperature, and fluid compatibility. This compliance reduces liability and enhances workplace safety. Non-compliant fittings may fail under pressure, causing equipment damage or even injury.

Regular inspections and batch testing are essential. High-quality suppliers provide full traceability documentation, which is crucial for safety-critical industries like construction, mining, and agriculture.

Service & Support

Service and support can make or break your experience with a hose fitting supplier. You need more than just quality hydraulic fittings; you need a partner who can respond quickly and provide expert guidance. The most valued services for heavy machinery operators include:

- Rapid on-site response from certified technicians

- Local presence for immediate support

- Fluid system expertise to optimize performance and connections

- Tailored solutions for specific applications, such as mining equipment or construction machinery

- Vendor managed inventory (VMI) for efficient stock management

- Rush deliveries and just-in-time (JIT) parts inventory

The table below highlights key service types and their benefits:

| Service Type | Description |

|---|---|

| Rapid On-Site Response | Certified technicians arrive quickly to minimize downtime and keep your projects on track. |

| Minimized Downtime | Suppliers focus on reducing downtime to maximize your productivity. |

| Prototype Construction | Support for product development and assembly as subcontracted components. |

| Compliance Certifications | Suppliers provide all necessary regulatory and compliance certifications as needed. |

You should expect your supplier to offer comprehensive support for fluid system challenges. This includes local specialist advice, solutions to save time, and services that reduce frustration. Reliable after-sales support ensures that your hydraulic components continue to deliver top performance throughout their lifespan.

Note: Regular product inspections by your supplier help prevent malfunctions and breakdowns. This practice enhances workplace safety and extends the life of your heavy machinery.

Evaluating Hydraulic Hose Fittings & Product Range

Material & Construction

When you select hydraulic fittings for heavy machinery, you need to consider both the material and construction. The right choice ensures durability and safety in demanding environments. Materials like stainless steel, Teflon (PTFE), and spiral wire reinforced hoses offer high resistance to extreme temperatures, chemicals, and pressure. These materials help your hydraulic components withstand harsh conditions found in mining, construction, and agricultural equipment.

| Material | Advantages | Applications |

|---|---|---|

| Stainless Steel | Resists corrosion and high temperatures | Aggressive fluids, outdoor machinery |

| Teflon (PTFE) | Handles chemicals and high heat | Harsh environments, specialized machinery |

| Spiral Wire Reinforced | Balances flexibility and pressure resistance | Construction and mining equipment |

| Steel Wire Braided | Adds strength for medium-pressure uses | Industrial hydraulic systems |

Construction features also matter. Corrugated designs allow for flexibility, while reinforced braiding adds strength. Specialty alloys like Inconel or Monel can further boost resistance to heat and corrosion. High-strength materials and advanced sealing technology ensure your hydraulic fittings perform reliably under pressure.

Application Compatibility

You must match your hydraulic hose fittings to the specific needs of your machinery. Using mismatched hoses or fittings can cause dangerous failures, leaks, or even equipment collapse. Always use hoses, fittings, and crimping equipment from the same hose fitting supplier. This practice reduces the risk of accidents and unplanned downtime.

Key factors for compatibility include:

- Pressure rating: Ensure fittings meet or exceed your system’s maximum pressure.

- Material compatibility: Choose materials that suit your hydraulic fluid and environment.

- Temperature rating: Select fittings that can handle your operating temperatures.

- Size: Match fitting size to hose and system requirements for proper flow and safety.

If you use incompatible materials or incorrect sizes, you risk rapid hose degradation, leaks, and safety hazards. Following manufacturer specifications and using matched components from a single supplier like Novafit helps you maintain system reliability and safety.

Product Variety

A broad product range from your hose fitting supplier gives you flexibility in maintenance and operations. Leading suppliers offer standard, custom, and eco-friendly hydraulic fittings to meet diverse industry needs. This variety ensures you can find the right solution for any application, from high-pressure mining equipment to specialized agricultural machinery.

| Type of Fitting | Benefits | Material Options |

|---|---|---|

| Standard Fittings | Reliable for general applications | Brass, Carbon Steel, PVC |

| Custom Fittings | Tailored for unique machinery requirements | Stainless Steel, Nylon |

| Eco-friendly Options | Reduce environmental impact | Biodegradable materials |

Suppliers with a wide selection of hydraulic fittings, hoses, and couplings help you minimize downtime. You gain quick access to the right hydraulic components for your equipment, which supports operational efficiency and performance. Novafit, for example, offers a comprehensive range that covers everything from industrial hoses to flexible tubing, ensuring you always have the right part for the job.

Tip: Always verify that your supplier can provide full traceability and warranty coverage for all hydraulic fittings. This support gives you peace of mind and helps maintain high quality standards in your operations.

Supplier Reputation & Experience

Industry Track Record

You need to look for suppliers with a proven industry track record. A strong history in supplying hydraulic fittings to sectors like construction, mining, and agriculture shows that a company understands the demands of heavy machinery. Years of experience often mean that the supplier has faced and solved many challenges related to hydraulic components. This experience helps you avoid costly mistakes and ensures that your equipment receives reliable parts.

A reputable supplier will have a portfolio of successful projects. You can ask for case studies or examples where their hydraulic fittings improved equipment performance in tough environments. Companies with a long-standing presence in the market usually invest in quality control and continuous improvement. This commitment leads to better product reliability and longer service life for your machinery.

Tip: Choose suppliers that have supported large-scale operations. Their experience with industrial equipment means they can anticipate your needs and provide solutions quickly.

Customer Reviews & References

Customer feedback gives you valuable insight into a supplier’s reliability. Verified reviews and references help you judge the quality of hydraulic fittings and the level of service you can expect. You should look for testimonials from other industrial buyers who use similar machinery.

The table below shows how different sources verify the authenticity of customer testimonials:

| Source | Description |

|---|---|

| Trustpilot | Reviews are verified to ensure authenticity, indicating that real customers are providing feedback. |

| Plumbing Supply | Customers give written permission for their testimonials to be displayed, ensuring credibility. |

| Mario Manufacturing | Encourages potential buyers to consider testimonials from actual customers, promoting trust. |

| Factory Direct Hose | Positive testimonials highlight customer satisfaction with both service and product quality. |

You can also request direct references from the supplier. Speaking with other clients who have purchased hydraulic fittings for heavy machinery gives you a clear picture of product quality and after-sales support. Reliable suppliers will not hesitate to connect you with satisfied customers.

Note: Consistent positive feedback from industrial clients signals that the supplier delivers high-quality hydraulic components and maintains strong relationships. This reputation helps you make confident purchasing decisions.

Supply Chain & Value

Delivery & Customization

You need a supplier who can guarantee the timely delivery of hydraulic fittings for your heavy machinery projects. Delays in the supply chain can slow down construction, mining, or agricultural operations and increase costs. Several factors influence the reliability of your supply chain:

- Material selection: The right materials ensure hydraulic fittings withstand harsh environments.

- Compatibility: Fittings must suit the fluids and pressures in your equipment.

- Pressure ratings: Always match fittings to your machinery’s requirements.

- Supplier reputation: Trusted suppliers help you avoid costly downtime.

Ongoing global supply chain disruptions have led to longer lead times for hydraulic components. Shortages of steel and brass, port congestion, and increased tariffs can all impact availability and cost. You should plan for these risks when choosing a supplier.

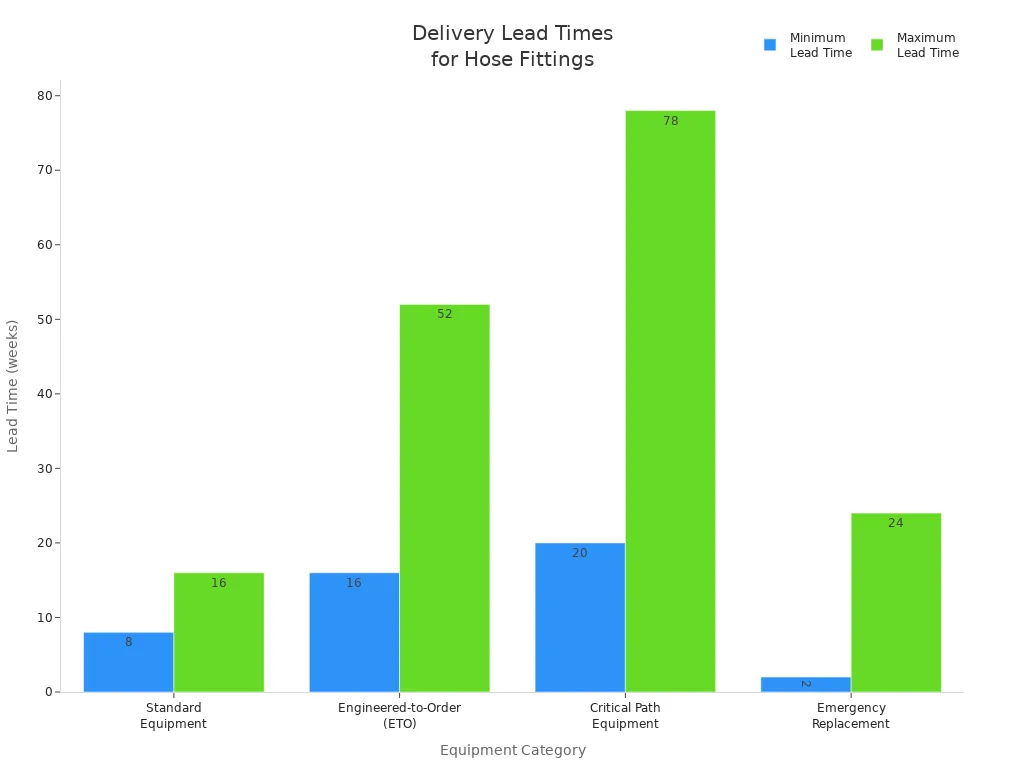

The table below shows typical delivery lead times for different equipment categories:

| Equipment Category | Lead Time Duration | Examples |

|---|---|---|

| Standard Equipment | 8-16 weeks | Standard motors, pumps, basic instrumentation |

| Engineered-to-Order (ETO) | 16-52 weeks | Custom process vessels, specialized automation |

| Critical Path Equipment | 20-78 weeks | Large turbines, custom manufacturing lines |

| Emergency Replacement | 2-24 weeks | Failed motors, damaged instruments |

Customization also matters. You may need fittings designed for unique machinery or specific site conditions. Leading suppliers offer custom fabrication and flexible solutions to meet your operational needs.

Tip: Ask your supplier about their ability to handle rush orders and provide emergency replacements. This support can keep your projects on schedule.

Cost Transparency

Cost transparency helps you make informed decisions when purchasing hydraulic fittings. Reliable suppliers provide clear pricing models and help you understand all cost drivers. You should always request the total landed cost, not just the unit price, to avoid hidden fees.

| Volume Tier | Discount Percentage | Minimum Order | Additional Benefits |

|---|---|---|---|

| Standard | 0-5% | $500 | Basic warranty |

| Preferred | 5-12% | $2,500 | Priority processing |

| Premium | 12-18% | $10,000 | Custom fabrication |

| Enterprise | 18-25% | $25,000 | Dedicated support |

Costs go beyond the initial purchase. High-quality hydraulic fittings and strong service reduce maintenance and replacement expenses over time. When you understand what drives costs, you can negotiate smarter and optimize your procurement strategy.

| Evidence Point | Description |

|---|---|

| Cost Drivers Understanding | Cost transparency helps you see what affects price, leading to better choices. |

| Informed Negotiations | Clear pricing lets you negotiate more effectively with suppliers. |

| Procurement Optimization | Transparency supports better alignment with your operational needs. |

Note: Evaluate suppliers based on the full landed price, including freight and tariffs. This approach ensures you get the best value for your investment and maintain high performance in your heavy machinery.

Supplier Verification Steps

Online Research & Platforms

You can start your supplier verification process by researching reputable online directories and platforms. These resources help you compare suppliers, review product offerings, and check for industry focus. For heavy machinery and industrial applications, consider these platforms:

| Platform Name | Description |

|---|---|

| Hose and Fitting Supply | Wide range of hydraulic and pneumatic equipment. |

| The source for hydraulic and pneumatic fluid supplies | Over 125,000+ products since 1999. |

| Hose in a Hurry | Quick access to fittings and hoses. |

| Hydraulics Direct | Stainless hose fittings and a learning center. |

You should also verify supplier certifications online. Request the certificate ID and issuance date. Use the certification body’s official registry to confirm validity. Check the supplier’s legal name, location, and scope. If you have doubts, contact the certifier directly.

Site Visits & Audits

Site visits and audits give you a clear view of a supplier’s operations. You can identify risks and ensure the supplier meets your standards for hydraulic components. Follow these steps for an effective visit:

- Define your objectives before the visit.

- Bring a cross-functional team for diverse insights.

- Prepare a checklist tailored to your needs.

- Observe material flow and inventory control.

- Engage with staff and ask questions.

- Speak with production floor employees for candid feedback.

- Review and summarize findings with your team.

Supplier audits help you maintain quality and spot vulnerabilities in the supply chain. They also improve communication and ensure compliance with safety and ethical standards.

Requesting Samples

Requesting product samples is a practical way to verify supplier claims. Evaluate samples using these criteria:

| Criteria | Explanation |

|---|---|

| Compliance with Standards | Check if hoses and fittings meet ISO and SAE requirements. |

| Performance Benchmarks | Test actual performance against manufacturer specifications. |

| Understanding Failure Modes | Analyze test failures to find weaknesses. |

| Usability and Safety Margins | Determine safety margins and expected operational life. |

| Environmental and Chemical Suitability | Ensure compatibility with hydraulic fluids and harsh environments. |

Testing samples helps you confirm product quality and performance before making large-scale purchases.

To choose a reliable hose fitting supplier for heavy machinery, you should:

- Check supplier certifications and quality standards.

- Review product range and ensure compatibility with your equipment.

- Investigate the supplier’s reputation and industry experience.

- Confirm supply chain reliability and delivery options.

- Request samples and conduct thorough verification.

Applying these steps helps you secure quality, compliance, and value for your industrial operations.

FAQ

What certifications should you require from a hose fitting supplier?

You should require ISO 9001, IATF 16949, ISO 14001, and ISO 45001 certifications. These show that the supplier meets international standards for quality, safety, and environmental management. Always request current certificates for verification.

How do you ensure hydraulic fittings match your heavy machinery?

You should match fittings, hoses, and crimping equipment from the same supplier. This practice ensures compatibility and safety. Always check pressure ratings, material compatibility, and size before installation.

Why does supplier experience matter for industrial applications?

Experienced suppliers understand the demands of construction, mining, and agricultural equipment. They help you avoid costly mistakes and provide reliable solutions. You benefit from their industry knowledge and proven track record.

What should you look for in after-sales support?

You should expect rapid response, technical guidance, and warranty coverage. Reliable suppliers offer on-site support, inventory management, and emergency replacements. This support keeps your operations running smoothly.

How can you verify product quality before a large order?

Request product samples and test them for compliance with ISO and SAE standards. Evaluate performance, durability, and compatibility with your machinery. This step helps you confirm quality before committing to a bulk purchase.