Why hydraulic hose supply matters in mining today

Table of Contents

You depend on hydraulic hose supply to keep mining operations safe, productive, and reliable. The right fittings and hose protection safeguard your equipment against harsh conditions. Neglecting industrial hose supply exposes you to risks:

- Hydraulic hose failures cause between 5% and 37% of unplanned hydraulic downtime in the mining industry.

Standardized hydraulics and protection double hose lifespan, cut downtime, and eliminate safety incidents.

Brands like Novafit deliver innovative solutions that help you achieve safer, more efficient mining.

Ensuring Reliable Hydraulic Hose Performance

- Reliable hydraulic hose supply is essential for safe and efficient mining operations. It prevents costly downtime and keeps equipment running smoothly.

- Choosing high-quality fittings and hoses reduces the risk of leaks and equipment failures. This practice extends the lifespan of your machinery.

- Implementing hose protection measures, like sleeves and heat shields, safeguards hoses from damage. This enhances durability and reduces maintenance costs.

- Regular inspections of hoses and fittings help catch small issues before they escalate. This proactive approach minimizes unexpected shutdowns and safety incidents.

- Partnering with trusted suppliers ensures you receive quality products that meet industry standards. This choice supports operational reliability and compliance.

Hydraulic hoses & fittings in mining

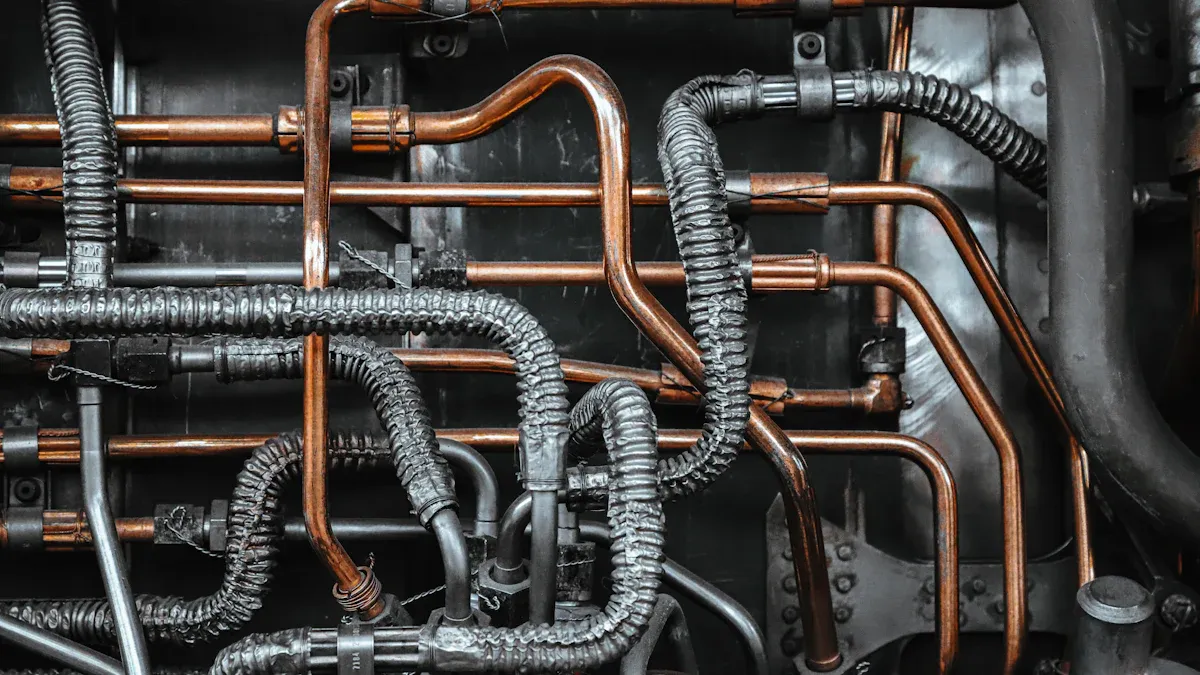

Essential role in mining equipment

You rely on hydraulic hoses and fittings to power critical mining equipment every day. These components transfer fluid power, enabling machines to drill, crush, and convey materials efficiently. Industrial hose assemblies play a vital role in excavators, loaders, and conveyors, ensuring precise control and reliable operation. Mining demands flexible hoses that withstand high pressure and extreme conditions. You often choose rubber hoses for their flexibility, strength, and abrasion resistance. Thermoplastic hoses offer lightweight construction and chemical resistance, making them ideal for specialized tasks. Teflon hoses handle aggressive fluids, while stainless steel hoses deliver durability in high-temperature and corrosive environments. Each industrial hose assembly must match the application to guarantee safety and performance.

- Common types of hydraulic hoses in mining:

- Rubber hoses: Flexible, strong, and abrasion-resistant

- Thermoplastic hoses: Lightweight, flexible, and chemically resistant

- Teflon hoses: Handle aggressive fluids and wide temperature ranges

- Stainless steel hoses: Resist high temperature and corrosion

How fittings impact performance

Fittings and hose protection directly affect the performance and reliability of your hydraulic systems. High-quality fittings ensure reliable connections and prevent leaks, even under high pressure. You need end fittings that meet rigorous testing standards to avoid catastrophic failures. Manufacturers test control valves and other components through pressure and destructive testing, ensuring they withstand operational demands. Non-destructive testing of raw materials and critical components further enhances safety and durability. By choosing the right fittings, you maintain the integrity of your industrial hose assemblies and extend the lifespan of your mining equipment.

Tip: Always select fittings that comply with industry standards for mining and industrial applications. This practice reduces downtime and boosts equipment reliability.

Hose protection for harsh environments

Mining exposes hoses to abrasion, heat, and chemical hazards. Hose protection measures shield your flexible hose from external damage, ensuring long-term durability. Protective sleeves and covers, such as nylon fabric hose sleeves, resist abrasion, crushing, and impact. Heat shields and fire sleeves provide thermal protection in high-temperature zones. High-performance wraps and abrasion guards protect against corrosion and mechanical wear. You must integrate hose protection into your maintenance strategy to maximize the service life of industrial hose assemblies in construction and mining.

| Protective Measure | Description |

|---|---|

| Protective Sleeves and Covers | Shield hoses from wear and damage; available in nylon and textile materials |

| Nylon Fabric Hose Sleeve | Resists abrasion, crushing, and impact; ideal for mobile machinery |

| Heat Shields and Fire Sleeves | Provide thermal protection; made from silicone-coated fiberglass |

By prioritizing fittings and hose protection, you ensure your mining operations run safely and efficiently, even in the harshest industrial environments.

Risks of poor hydraulic hose supply

Downtime in the mining industry

You face significant operational risks when your hydraulic hose supply falls short. In the mining industry, even a brief interruption can halt production lines and disrupt schedules. Hydraulic hose failures often lead to unplanned downtime, which can cost you an average of $130,000 per hour. Environmental degradation causes nearly 35% of these failures, making it a leading factor in lost productivity. Routine inspections help you catch small issues before they escalate, but without a reliable supply of quality hoses and fittings, you risk frequent breakdowns that can cripple your operations.

- Key impacts of downtime in mining:

- Lost production time

- Delayed project timelines

- Increased pressure on maintenance teams

Note: Every hour of downtime not only affects your bottom line but also puts your reputation at risk with clients and stakeholders.

Safety hazards and compliance

Poor hydraulic hose supply exposes your workforce to serious safety hazards. Leaking or burst hoses can cause high-pressure fluid injection injuries, fires, or equipment malfunctions. These incidents threaten the well-being of your team and can result in regulatory penalties. You must comply with strict industry standards to maintain a safe work environment. The following table outlines key regulatory requirements for hydraulic hose supply in mining:

| Standard | Description |

|---|---|

| SAE | Regulates hose construction, performance, and pressure ratings across industries. |

| ISO | Ensures hoses are manufactured and tested to reliable benchmarks. |

| EN | Preferred in Europe, covering hose dimensions, performance criteria, and burst pressure ratings. |

You need fittings and hoses that meet or exceed these standards to ensure compliance and protect your team. Failing to do so can lead to costly shutdowns, legal action, and damage to your company’s reputation.

Increased costs and repairs

When you rely on poor-quality hydraulic hose supply, your maintenance and repair costs rise sharply. Frequent hose failures force you to replace components more often, driving up expenses and straining your budget. You also face the risk of equipment damage, which can require extensive repairs and lead to further downtime. The mining industry loses an estimated $3 billion annually due to equipment downtime from hose failures. Poor fittings and hoses disrupt your operations and reduce the lifespan of your machinery.

- How poor hydraulic hose supply increases costs:

- More frequent replacements of substandard hoses

- Higher maintenance costs due to repeated failures

- Costly repairs from equipment damage and lost productivity

Tip: Investing in high-quality fittings and hoses reduces long-term costs and keeps your mining operations running smoothly.

By prioritizing reliable hydraulic hose supply, you protect your business from unnecessary downtime, safety incidents, and escalating repair costs. You also ensure compliance with industry standards, safeguarding both your workforce and your bottom line.

Benefits of a reliable hose supply

Boosting mining efficiency

You drive mining efficiency by investing in a reliable hydraulic hose supply. High-quality industrial hose assemblies minimize downtime and keep your equipment running. When you use durable flexible hoses and fittings, you reduce maintenance costs and maximize uptime. Mining operations depend on continuous production, so every minute counts. Reliable hose protection and end fittings optimize hydraulic systems, allowing your machines to perform at peak levels.

- Increased uptime ensures your mining equipment operates without interruption.

- Reduced maintenance costs help you allocate resources more effectively.

- Improved efficiency means your team completes projects faster and meets deadlines.

Mining industry leaders report that advanced industrial hose assembly solutions, such as MXG hoses, excel under high-pressure and impulse conditions. These components require fewer replacements and lower maintenance, which boosts operational efficiency. Gaskets and hydraulic systems also contribute to reliable operation, enhancing overall productivity. As the mining and construction sectors expand, the demand for durable hose solutions continues to grow. You rely on a consistent supply to maintain operational effectiveness in harsh environments.

Enhancing equipment longevity

You extend the lifespan of your mining equipment by choosing high-quality fittings and hose protection. Industrial hose assemblies designed for mining withstand extreme pressure, temperature, and environmental exposure. Flexible hoses and robust fittings reduce the risk of premature wear and tear.

- High-quality hydraulic hoses ensure the smooth operation of heavy machinery.

- Proper routing and regular inspections significantly extend hose life.

- Selecting the right materials and specifications is crucial for longevity and safety.

Mining equipment faces constant stress from demanding applications. When you implement best practices, such as regular inspections and proper hose protection, you enhance reliability and reduce costly repairs. Industrial hose assemblies built for mining and construction environments deliver the flexibility and durability needed for long-term performance. You protect your investment and maintain productivity by prioritizing quality components.

Improving workplace safety

You create a safer workplace by maintaining a reliable hydraulic hose supply and investing in advanced hose protection. Safety remains a top priority in mining, where equipment operates under high pressure and harsh conditions. Failed fittings and hoses often cause hydraulic fluid spills, which pose significant risks. Studies show that hydraulic fluid was involved in 74% of spill incidents, with failed hoses and fittings as the most common causes.

- Improved maintenance and quality control reduce incident rates.

- Protective sleeves prevent leaks, ruptures, and spills, enhancing operator safety.

- Abrasion protection prolongs hose lifespan and reduces workplace hazards.

| Safety Feature | Benefit |

|---|---|

| Protective sleeves for hoses | Prevents leaks, ruptures, and spills, enhancing operator safety. |

| Abrasion protection | Protects hoses against wear and tear, prolonging their lifespan. |

MSHA-approved hoses offer flame resistance, high-pressure ratings, and chemical compatibility. These features ensure reliability and safety in mining operations. You minimize fire risks, limit toxic smoke, and improve system integrity during emergencies. By integrating fittings and hose protection into your maintenance strategy, you safeguard your workforce and comply with industry standards.

Reliable hydraulic hose supply supports mining efficiency, equipment longevity, and workplace safety. You benefit from flexible solutions, robust protection, and high-performance components that keep your industrial operations running smoothly.

Hose supply considerations for mining

Choosing quality fittings and suppliers

You need to select suppliers who deliver consistent quality and reliability for your mining operations. Look for manufacturers who meet international standards and hold key certifications. These benchmarks ensure your industrial hose assemblies perform under high pressure and harsh conditions.

- SAE and ISO standards set the bar for hydraulic hose quality and performance.

- ISO 9001 and ISO 18752 certifications confirm a supplier’s commitment to quality and compliance.

- MSHA and Coast Guard certifications are essential for high-temperature and safety-critical applications.

Novafit stands out with a broad product range, including end fittings and adapters for industrial, construction, and mining industry needs. Their ISO 9001, ISO 14001, and CE certifications demonstrate a focus on safety, flexibility, and durability. You benefit from a supplier who prioritizes rigorous testing and continuous improvement.

| Evidence Point | Description |

|---|---|

| Reliability Impact | High-quality suppliers ensure hoses meet stringent industry standards, reducing failures and downtime. |

| Cost Savings | Each hose failure can cost tens of thousands, highlighting the financial impact of quality control. |

| Operational Efficiency | Standardized procurement and quality control are essential for sustainable and safe hydraulic operations. |

Inventory and supply chain management

You must manage inventory and supply chains to avoid costly delays in mining. Real-time tracking and AI-driven supply chain management improve lead times and inventory turnover. Diversifying suppliers protects your operations from disruptions caused by geopolitical or environmental factors.

| Strategy | Benefits |

|---|---|

| AI-Driven Supply Chain Management | Improves lead times and inventory turnover, supporting just-in-time delivery models. |

| Real-time Tracking | Provides visibility into the supply chain, allowing proactive issue resolution and efficiency. |

| Diversification of Suppliers | Mitigates risks from geopolitical tensions and climate shifts, ensuring supply chain resilience. |

Delays in delivering hydraulic hoses to remote mining operations frequently disrupt critical equipment performance and inflate operational costs. In complex, layered supply chains, identifying bottlenecks, deploying logistics software, and planning contingencies are essential to safeguarding uptime.

Technical support and custom solutions

You gain a competitive edge by partnering with suppliers who offer technical support and custom solutions. Leading manufacturers provide hydraulic service and repair, custom industrial hose assembly fabrication, and system design services. These offerings ensure your flexible hoses and fittings match your unique mining and construction requirements.

| Service Type | Description |

|---|---|

| Hydraulic Service & Repair | Comprehensive repair services for hydraulic systems. |

| Hydraulic Hose Assembly Fabrication | Custom fabrication of hydraulic hose assemblies tailored to specific needs. |

| Hydraulic System Design | Design services for hydraulic systems to optimize performance and efficiency. |

| Technical Support | Expert assistance and guidance for hydraulic applications and products. |

Custom hoses withstand extreme pressure, abrasive materials, and variable temperatures. Manufacturers like Novafit use rigorous testing and a comprehensive database of application-specific requirements to deliver industrial hose assemblies with unmatched flexibility and protection. Ongoing investment in research and development ensures your equipment stays ahead of future challenges. By choosing suppliers who offer technical expertise and tailored solutions, you maximize safety, flexibility, and operational efficiency in the mining industry.

Real-world impact: Good vs. poor supply

Preventing breakdowns in mining

You face constant pressure to keep your mining operations running without interruption. Proactive management of industrial hose assemblies helps you prevent costly breakdowns. When you select high-quality fittings and invest in robust hose protection, you minimize the risk of leaks and equipment failures. For example, hydraulic excavators and shovels benefit from JIC fittings that deliver reliable connections. Wheel loaders use ORB fittings and clamps to create tight seals and secure hoses, reducing wear. High-pressure water cannons rely on advanced protection products to shield hoses from abrasion and heat. These strategies extend the lifespan of industrial hose assemblies and keep your equipment performing at peak levels.

| Application | Hose Protection Strategy |

|---|---|

| Hydraulic Excavators & Shovels | Use of JIC fittings for reliable connections and flange fittings for heavy-duty lines to prevent leaks. |

| Wheel Loaders | ORB fittings create tight, leak-free seals; clamps secure hoses to prevent wear. |

| High-Pressure Water Cannons | RHINO hose protection products shield hoses from abrasion, heat, and impact, extending their lifespan. |

Novafit supports your operations with a wide range of industrial hose assemblies designed for mining and construction environments. Their products meet rigorous standards, helping you avoid unplanned downtime and maintain productivity.

The cost of supply chain failure

Supply chain disruptions can cripple your industrial operations. When you experience delays in sourcing industrial hose assemblies, your equipment sits idle and your costs escalate. Poor supply management leads to frequent breakdowns, emergency repairs, and lost revenue. You may face project delays and strained relationships with clients. In contrast, reliable suppliers like Novafit offer consistent delivery, technical support, and custom solutions. You gain peace of mind knowing your industrial hose assemblies will arrive on time and meet your specifications.

Tip: Partnering with a supplier who understands the demands of mining and construction helps you avoid costly interruptions and maintain operational efficiency.

You protect your bottom line by prioritizing quality, reliability, and responsive service in your supply chain. Investing in superior industrial hose assemblies and fittings ensures your equipment stays productive and your business remains competitive.

You play a crucial role in keeping mining operations efficient and safe by managing hydraulic hose supply. Industry research highlights several key points:

- Hydraulic hoses power essential machinery, such as dozers and haul trucks.

- Delayed wear detection often leads to unexpected shutdowns and safety incidents.

- Nearly 40% of equipment failures result from hose or fitting malfunctions.

By choosing reliable suppliers like Novafit, you ensure operational reliability and reduce downtime. Prioritizing high-quality hydraulic hose supply and routine inspections helps you boost productivity and protect your investment.

FAQ

What makes industrial hydraulic hose supply critical for mining operations?

You depend on industrial hydraulic hose supply to keep mining equipment running. Industrial hoses power drills, loaders, and conveyors. Reliable supply prevents downtime and supports safe, continuous production. Industrial hose assemblies withstand harsh environments, making them essential for mining efficiency and safety.

How do you choose the right industrial hose fittings for your equipment?

You select industrial hose fittings by matching them to your equipment’s pressure, temperature, and fluid requirements. Industrial applications in mining and construction demand fittings that meet strict standards. Always verify compatibility with your industrial machinery to ensure leak-free, reliable performance.

Why is hose protection important in industrial environments?

You protect industrial hoses from abrasion, heat, and chemicals to extend service life. Industrial mining sites expose hoses to constant wear. Using protective sleeves and guards reduces failures and keeps your industrial equipment operating safely and efficiently.

How does inventory management impact industrial hose supply?

You maintain industrial productivity by managing inventory effectively. Industrial operations in remote mining locations rely on timely hose deliveries. Real-time tracking and supplier partnerships help you avoid shortages, keeping your industrial machinery active and reducing costly delays.

What support should you expect from an industrial hose supplier?

You should expect technical support, custom industrial hose solutions, and fast response times. Industrial suppliers like Novafit offer product selection guidance, assembly fabrication, and troubleshooting. This support ensures your industrial equipment meets operational demands and stays compliant with industry standards.