Which Hydraulic Adapter Works Best for Heavy-Duty Jobs

Choosing the right hydraulic adapter helps your equipment handle high pressure. It also makes sure your machines work well and do not break down often. JIC, ORFS, and stainless steel adapters are used a lot in tough jobs. They are chosen because they follow strict industry rules.

| Adapter Type | Key Features | Common Applications |

|---|---|---|

| JIC | 37° flare seating surface, withstands up to 10,000 PSI | Construction, mining, agricultural machinery |

| ORFS | Reliable, leak-free connection, resistant to vibration | Aerospace, defense, automotive hydraulics |

| Stainless Steel | Excellent corrosion resistance, ideal for high-pressure applications | Marine, aerospace, food processing, chemical industries |

Using strong adapters helps stop leaks and breakdowns. This saves money and time. The need for these adapters is expected to grow by 3.7% each year from 2025 to 2033. This is because more people are using hydraulic systems in different industries. Novafit is a company that makes special adapters. Their products are known for being very reliable and working well in tough places.

Key Takeaways

- Picking the right hydraulic adapter helps stop leaks and breakdowns. This saves you both time and money.

- Look at pressure ratings, material strength, seal quality, and corrosion resistance. These things matter when you pick an adapter for tough jobs.

- Always use certified products like Novafit. This keeps you safe and makes sure you meet industry rules.

- Installing hydraulic fittings and adapters the right way is very important. It keeps your system working well and stops expensive problems.

- Novafit has many strong adapters and expert help. This makes it simple to find what you need for your job.

Hydraulic Adapter Performance

When you pick a hydraulic adapter for tough jobs, you should think about four main things. These are pressure ratings, material strength, seal integrity, and corrosion resistance. These things help your machines work well and last longer. Novafit hydraulic adapters follow strict rules from around the world. They have special certificates that show they work well and last a long time.

Pressure Ratings

Your hydraulic adapter must handle high pressure without breaking. Groups like SAE and ISO set rules for how much pressure adapters can take. These rules help you compare different adapters. You can pick the one that fits your machine best.

| Standard | Description |

|---|---|

| SAE | Gives rules for hydraulic fittings. These rules help keep machines safe and working well. |

| ISO | Makes rules for size, threading, and pressure. These rules help parts fit together in many jobs. |

Adapters that follow these rules are strong and safe. Novafit tests their products a lot. They make sure every adapter meets or beats these rules. This helps you trust every connection.

Material Strength

The material of your hydraulic adapter is very important. It needs to be strong enough for high pressure and hard work. Here is a simple chart about common materials:

| Material | Key Properties | Tensile Strength Comparison |

|---|---|---|

| Stainless Steel | Does not rust, very strong, good for tough places | High |

| Brass | Easy to shape, good for lower pressure | Moderate |

| Aluminum | Light, moves heat well, not as strong as steel | Low to Moderate |

| Carbon Steel | Very strong, needs a coating to stop rust | High |

| Special Alloys | Made for very hard jobs, great against heat and chemicals | Very High |

- Stainless steel is good for factories and ships because it is tough.

- Brass is cheaper and works for many jobs.

- Aluminum is best when you need light parts, like in planes.

- Carbon steel is strong and good for heavy work, but it needs a coating.

- Special alloys are the strongest for the hardest jobs.

Novafit uses top materials and smart ways to make adapters. This makes sure each one is strong and works well.

Seal Integrity

A good seal stops leaks and keeps your hydraulic system working right. You should pick adapters with smart seals:

- Y-ring seals change shape with pressure and heat. They stop leaks well.

- Cup seals get bigger when under pressure. They are good for cylinders and actuators.

- O-ring seals with backup rings last longer and stop leaks in high pressure.

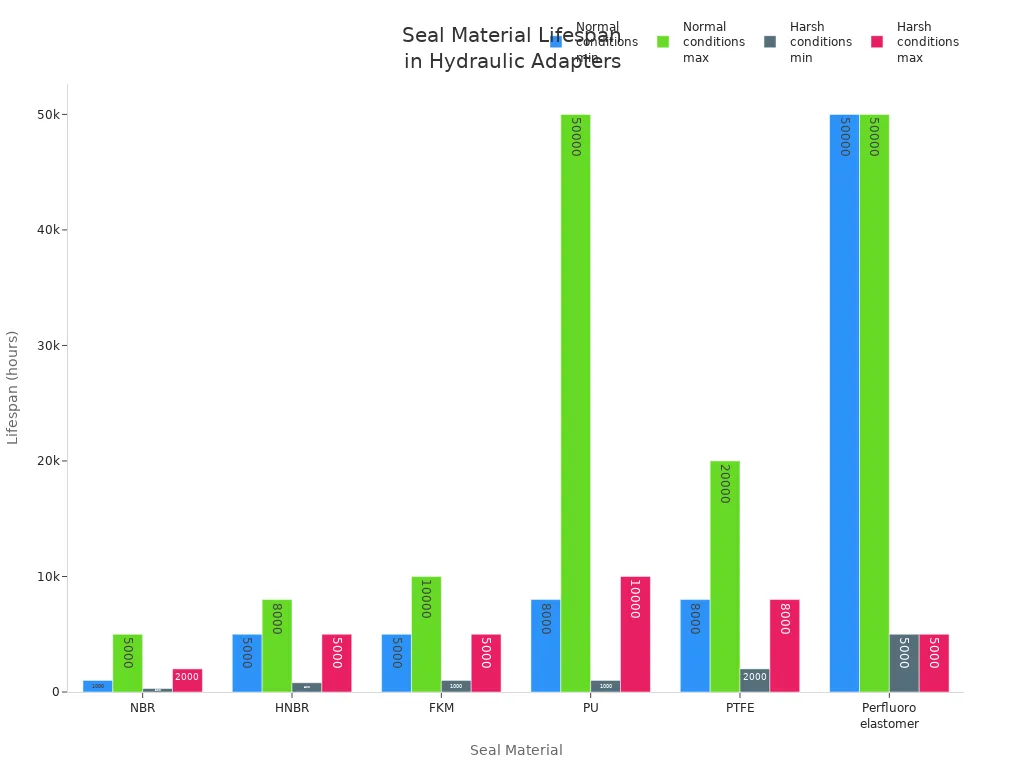

These seals are used in cylinders, pumps, motors, and big machines. The seal material also matters. Polyurethane and PTFE seals can last up to 50,000 hours if used right. FKM and HNBR seals work well in tough places.

Novafit adapters use great seals to help your machines run longer and need less fixing.

Corrosion Resistance

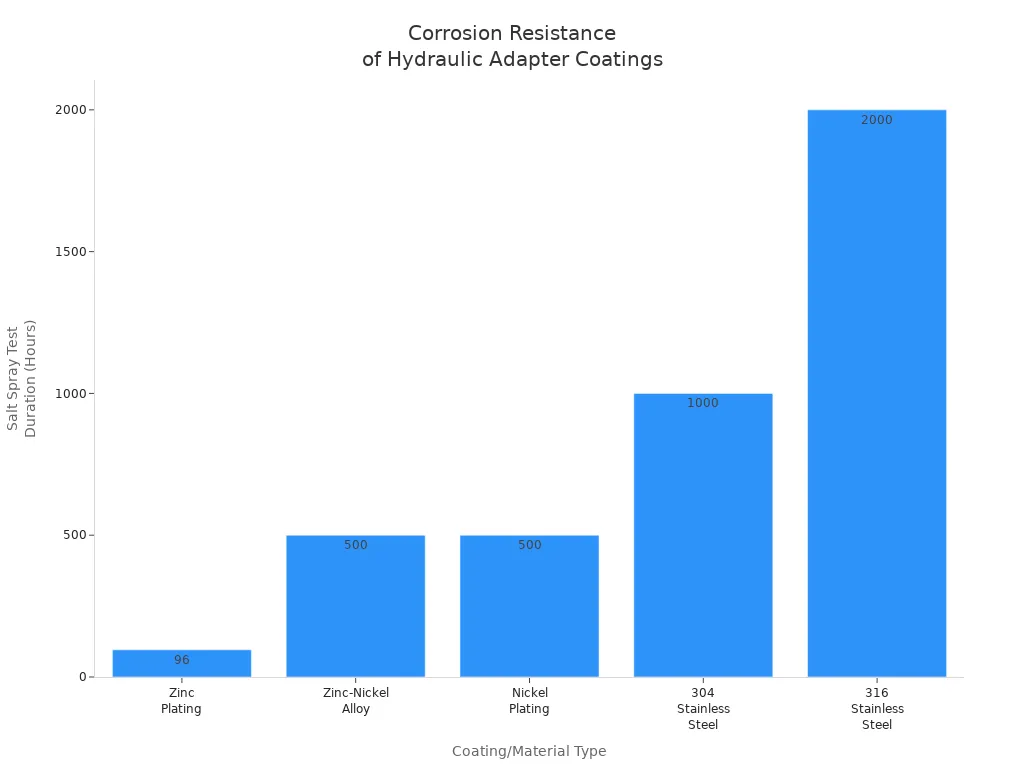

Corrosion can make your hydraulic adapter break faster. You need adapters with coatings or materials that fight rust and damage. Here is a chart to show how coatings and materials compare:

| Coating Type | Salt Spray Test Duration (Hours) | Best Resistance To |

|---|---|---|

| Zinc Plating | 96 – 240 | Good for most jobs |

| Zinc-Nickel Alloy | 500 – 1,000 | Good for some rust |

| Nickel Plating | 500 – 1,200 | Good against wear and chemicals |

| 304 Stainless Steel | 1,000 – 2,000 | Good for some rust and water |

| 316 Stainless Steel | 2,000+ | Best for sea water and hard places |

Stainless steel, especially 316, gives the best protection in water and chemical places. Novafit has adapters with strong coatings and stainless steel. This helps your machines stay safe even in hard jobs.

Tip: Always look for certificates when picking a hydraulic adapter. Novafit has ISO 9001, ISO 14001, and CE certificates. This means their products are safe, high quality, and good for the environment.

| Certification | Description |

|---|---|

| ISO 9001 | Shows the company has good quality control |

| ISO 14001 | Shows the company cares for the environment |

| CE | Shows the product is safe and follows rules |

If you focus on these things and pick certified products, your hydraulic systems will work better and last longer. Novafit works hard to make adapters that are strong and safe for a long time.

Hydraulic Fittings and Adapters: Selection

Picking the right hydraulic fittings and adapters is important. This helps your machines work well, stay safe, and last longer. You need to think about adapter types, size, fit, and how to install them. These steps help stop leaks, breakdowns, and wasted money. Novafit gives you many choices and expert help. This makes picking the right part easy and fast.

Adapter Types

You will see many kinds of hydraulic fittings and adapters at work. Each kind is made for a special job or rule. It is important to use the right adapter for your machine. This helps your system work better and follow the rules.

| Fitting Type | Description | Common Applications |

|---|---|---|

| JIC | 37-degree flare fittings, used in high-pressure applications. | North American machinery, military vehicles |

| ORFS | Flat-faced fittings with O-ring seals, excellent for zero-leak connections. | Heavy-duty, leak-free performance |

| NPT | Threaded connections that seal through thread deformation. | Industrial applications |

| BSP | British Standard Pipe fittings, used in older UK-based machinery. | Agriculture, construction equipment |

| SAE | Standardized fittings for American-made machinery. | Heavy-duty equipment, military vehicles |

| Metric | Standardized globally (DIN, ISO), high precision and repeatability. | International applications |

Always use the adapter type your machine needs. JIC and ORFS adapters are good for high pressure and shaking. NPT and BSP adapters fit older or special machines. SAE and Metric adapters work for systems used around the world.

Tip: Using the right hydraulic fittings and adapters helps your system work well, stops leaks, and follows the rules.

Sizing and Compatibility

Getting the size and fit right is very important for safety and how well your system works. When you pick hydraulic fittings and adapters, make sure every part fits just right.

- The right size lets fluid move well and keeps pressure steady.

- The wrong size can cause problems and cost you time and money.

- Picking the right size and fit keeps the connection tight and leak-free.

- If sizes do not match, you might get leaks or lose pressure.

- You must measure the outside, inside, and thread size carefully.

- A good fit stops shaking and movement that can break parts.

- If it is too tight, threads can wear out or break.

- The wrong size can make your system work less well and wear out faster.

- Leaks and failures can happen if the size is wrong.

Mixing different brands or types can cause problems:

- Different pressure ratings can make weak spots and leaks.

- Wrong materials can react and hurt the seals.

- Threads that do not match can make bad fits and leaks.

| Aspect | Compliant Adapters | Non-Compliant Adapters |

|---|---|---|

| Compatibility | Fit together properly, ensuring efficiency | May not fit, leading to leaks and damage |

| Safety | Meet safety criteria, enhancing reliability | Can cause safety hazards |

| Regulatory Compliance | Meet industry standards, avoiding fines | May lead to legal issues and fines |

| Performance | Consistent performance across systems | Can result in inefficiencies and failures |

| Sourcing Replacement Parts | Easier to find compatible parts | Difficult to source replacements |

Note: If adapters are too small, they can block fluid and lower pressure. This makes your pump work harder and can cause it to get hot, wear out, or slow down.

Installation Practices

Putting in hydraulic fittings and adapters the right way is very important. Good installation keeps your system strong and working well. Following the best steps helps stop leaks and breakdowns, even when pressure is high.

- Select the Right Fitting: Pick by pressure, fluid, and connection type.

- Prepare the Components: Clean all parts to remove dirt.

- Apply the Correct Sealing Method: Use the right sealant or tape as needed.

- Properly Tighten the Fitting: Use the right amount of force to avoid damage.

- Inspect for Leaks: Check for leaks and test after you finish.

🛠️ Pro Tip: Always follow the maker’s rules when you install. This helps your hydraulic fittings and adapters work as they should and keeps your system strong.

Novafit gives you full help with picking, installing, and fixing products. If you need something special, Novafit can make custom hydraulic fittings and adapters just for you.

| Service Type | Description |

|---|---|

| Technical Support | Comprehensive support for product selection, installation guidance, and troubleshooting |

| Custom Solutions | Design and manufacture of custom fittings for specific applications and requirements |

You can trust Novafit’s team and factory to give you hydraulic fittings and adapters for tough jobs. Their focus on quality and help lets your hydraulic systems work well and follow the rules for a long time.

Product Recommendations

Comparisons

When picking hydraulic adapters for hard jobs, you want to know how brands do. Novafit is special because it works with high pressure and is simple to put in. Its leak-proof design keeps fluid inside. Novafit adapters are strong and last a long time. They help machines work longer and have fewer problems. The table below lists the main good and bad points of Novafit hydraulic adapters:

| Advantages | Disadvantages |

|---|---|

| High-pressure capabilities | Susceptibility to damage from over-tightening |

| Easy installation | Limited reusability due to metal-to-metal sealing |

| Leak-proof design | |

| Versatility | |

| Durability | |

| Cost-effectiveness | |

| Increased efficiency |

Novafit makes more than 10 million adapters each month. This means you can order a lot and not worry about running out. Many other companies cannot make this many adapters. You get the same good quality and quick shipping, even for big orders.

Note: Novafit’s adapters follow strict industry rules. You can trust them in places with high pressure and lots of force.

Use Cases

You need adapters that work in tough places like building sites, factories, and mines. Novafit hydraulic adapters help fix common problems in these places:

- Novafit fittings keep a tight seal, so dust and dirt do not cause leaks.

- Your machines keep working, even when there is a lot of shaking or strong hits.

- You have less surprise downtime because Novafit makes adapters extra tough.

People who use Novafit adapters say they stay strong in hard places. You also get help and custom solutions for your needs. This trust helps you finish jobs on time and keep your work going.

When you pick Novafit, you get long-term value. You get adapters that are reliable, can grow with your business, and come with good customer service. Your business stays busy and strong in hard industries.

When you pick hydraulic adapters for high pressure, look at the pressure rating, what materials work together, the temperature range, the size, and how the seal works. Certified products last longer and help your machines stay safe. Novafit gives new ideas and makes special fittings for tough jobs. You can save money by asking experts and checking certificates before you buy. For hard projects, engineers and consultants give special help and make sure your system works its best.

FAQ

What certifications do Novafit hydraulic adapters have?

Novafit adapters have ISO 9001, ISO 14001, and CE certificates. These show the products are safe, high quality, and good for the environment. You can trust them for tough jobs in factories.

How do you choose the right hydraulic adapter for high-pressure jobs?

Look at the pressure rating, material strength, and seal type. Make sure the adapter fits what your system needs. Novafit can help you pick the best one for your job.

Can Novafit provide custom hydraulic fittings for unique industrial needs?

Yes. Novafit can make special hydraulic fittings and adapters. You can ask for parts made just for your equipment or project.

What support does Novafit offer for installation and troubleshooting?

Novafit’s team helps with picking, installing, and fixing products. You get expert advice to keep your machines working and avoid problems.

How does Novafit ensure long-term reliability in harsh environments?

Novafit uses strong materials and special coatings. Their adapters fight rust, keep seals tight, and work well in tough places.