How to Identify the Best Hydraulic Hose Fittings for Your Machinery

You need to pick hydraulic hose fittings that fit your machine. Think about the fitting type, size, and what it is made of. Make sure the fitting matches your hydraulic hose and how you use it. Pressure rating, diameter, and thread type are important. Choose if you want a permanent or reusable Hydraulic Hose Fitting. Picking the wrong fitting can break equipment or hurt people. It can also cause spills or stop work for a long time. The right Hydraulic Product keeps your system safe and your workplace protected.

Key Takeaways

- Always check that the pressure rating matches your system’s highest pressure. This helps stop dangerous problems from happening.

- Pick the right size and diameter for fittings. This makes sure fluid flows well and stops overheating or blockages.

- Choose materials that do not rust and fit your work area. This helps fittings last longer and keeps them safe.

- Find the correct thread type for a tight seal. If threads do not match, leaks and failures can happen.

- Look at your hydraulic hoses and fittings often for damage. This helps you spot problems early and keeps things safe.

Key Factors for Right Hydraulic Hose Fittings

When you pick hydraulic hose fittings, you need to think about a few things. These things help your machine work safely and well. If you choose wrong, you might get leaks or have to fix things often.

Pressure Rating

You should look at the pressure rating before you buy hydraulic hose fittings. The pressure rating shows how much force the hose and fitting can take. If the rating is too low, the fitting might break and cause danger.

Tip: Always make sure the pressure rating of your hydraulic hose fittings matches the highest pressure your system will have.

Here is a table with common pressure rating standards:

| Standard | Description |

|---|---|

| SAE J517 | Rules for hydraulic hoses in North America. |

| ISO 18752 | Groups hoses by pressure and flow. |

| 100R1, 100R2 | SAE J517 types for one- and two-wire hoses. |

| 100R7 | Non-conductive design for safety. |

| 100R17 | Hose with 3,000 psi working pressure. |

| 100R13, 100R15, 100R19 | New SAE J517 standards for different hose sizes. |

If you go over the pressure rating, bad things can happen. You might see hose bursts, people get hurt, or the environment gets damaged. The table below shows what could happen:

| Risk Type | Description | Possible Consequences |

|---|---|---|

| Catastrophic Failure | Hose breaks and fluid comes out fast | Danger to workers, flying bits, hose snaps back |

| Injuries | Fluid comes out with high pressure | Bad injuries, work stops |

| System Damage | Pressure jumps when hose bursts | Expensive repairs, less trust in system |

| Operational Downtime | Hose fails suddenly | Work stops, money lost |

| Leaks | Too much pressure makes hose weak | Machine works worse, hidden dangers |

| Spills | Lots of fluid comes out | Slippery floors, safety risk |

| Contamination | Oil leaks and spreads | Pollution, fines |

| Environmental Damage | Oil gets in soil or water | Cleanup costs, legal trouble, bad reputation |

Size and Diameter

You need to measure the size and diameter of your hydraulic hose and fittings. If you pick the wrong size, fluid does not move right. This can lower pressure and make your machine less good. Big fittings make fluid swirl, small ones block flow and make things hot. These problems use more energy and can break your system.

Note: Always match the diameter of your hydraulic hose fittings to what your system needs. This helps your machine work well.

Material Selection

The material of your hydraulic hose fittings matters for strength, rust resistance, and how long they last. Pick a material that fits your work place and the fluid you use. Here is a table with common materials and their good and bad points:

| Material | Advantages | Disadvantages |

|---|---|---|

| Steel | Strong, useful, not expensive | Can rust, heavy |

| Stainless Steel | Great against rust, good for high pressure | Costs more, hard to shape |

| Brass | Good against rust, easy to shape | Not for high pressure, can rust in some fluids |

| Aluminium | Light, does not rust | Not very strong, can bend under force |

- Steel is strong and good for high pressure, but it can rust.

- Stainless steel does not rust and lasts longer, but costs more.

- Brass is easy to shape and good for lower pressure, but not for hard jobs.

- Aluminium is light and does not rust, but cannot take high pressure.

Engineers often pick stainless steel or special plastics for tough places. These materials do not rust and last longer, especially in places like oil rigs or mines.

Fluid and Temperature Compatibility

You must check that your hydraulic hose and fittings can handle the fluids and heat in your system. If the materials do not match the chemicals or heat, the hose can break and leak.

- Make sure the hose’s inside, middle, and outside all resist the fluids you use.

- Check that fluid and air temperatures stay in the hose’s safe range.

- Keep hoses away from things that make them too hot.

- Think about fluid pressure, temperature, strength, and time when you pick materials.

- Always ask makers about what works, because ratings can change with heat.

If you ignore fluid and temperature compatibility, you might get leaks, broken systems, and expensive repairs.

Thread Type

Thread type is important when you pick hydraulic hose fittings. The right thread type makes a tight seal and stops leaks. Common thread types are:

- NPT/NPTF (National Pipe Taper/Fuel)

- UN/UNF (Unified National/Fine)

- BSPP (British Standard Pipe Parallel)

- BSPT (British Standard Pipe Tapered)

- Metric parallel

- Metric tapered

To find the thread type, you should:

- See if the thread is tapered or straight.

- Measure the space between threads.

- Measure the size.

- Name the thread.

Using the right thread type keeps your hydraulic couplers and connections safe. If threads do not match, you can get leaks and broken systems.

Types of Hydraulic Hose Fittings

Picking the right hydraulic hose fitting keeps machines safe. Each type has its own good points and best uses. You need to know when to use each one.

Permanent Fittings

Permanent fittings go on the hose with a crimping tool. Once they are on, you cannot take them off or use them again. These fittings are good for places where things do not move. They work well in high-pressure jobs and tough places. You often see them on big machines that stay in one spot. They are used where hoses do not need changing much.

| Feature | Permanent Fittings |

|---|---|

| Installation | Needs crimping tools |

| Reusability | Not reusable |

| Maintenance | Hard to replace |

| Flexibility | Limited to certain hose types |

| Risk of Failure | Low if installed correctly |

Permanent fittings give a strong and leak-free join. Pick them when you want something that lasts a long time.

Reusable Fittings

Reusable fittings screw onto the hose by hand. You do not need special tools for these. You can take them off and use them again and again. These fittings are good when you must change hoses a lot. People use them for quick repairs or when working outside. Mobile workers, car shops, and plant teams use them for fast fixes.

- You can put reusable fittings on right where you are.

- They help you fix things quickly and save money.

- They are great for quick repairs and small jobs.

| Feature | Reusable Fittings |

|---|---|

| Installation | No special tools needed |

| Reusability | Can be reused many times |

| Maintenance | Easy to replace and maintain |

| Flexibility | Fits many hose types |

| Risk of Failure | Needs careful installation |

If a hose breaks, reusable fittings help you fix it fast.

Threaded Connections

Threaded connections use male and female threads to join hoses. You screw them together to make a tight seal. These joins are strong and last a long time. You find them in high-pressure jobs and places where you want a join to stay put.

- Threaded connections are strong and last long.

- They help stop leaks in hard jobs.

- Use them when you need a safe and lasting join.

Quick-Release Couplings

Quick-release couplings let you join and unjoin hoses fast. You do not need any tools for this. These couplings make fixing things easy and save time. They also help stop leaks and keep pressure steady.

- Quick-release couplings make work safer and faster.

- They are good when you must change hoses a lot or move things.

- You see them on machines that move and need quick hose swaps.

Quick-release couplings help your hydraulic system work well with less work.

How to Choose the Right Hose

Assess System Needs

First, you need to know what your hydraulic system needs. This helps you avoid mistakes and keeps your machine safe. Here are some steps to help you:

- Find out the pressure, flow, and temperature your system will have.

- Think about how you use your machine and its design.

- Pick fittings that can take the highest pressure and any sudden changes.

- Make sure the fittings work with your fluid to stop leaks and rust.

- Look at where you use the machine. Dust, water, or chemicals can change what material you need.

- Know how fast the fluid moves. This helps you pick the right hose and fittings.

- Match the flow speed with the fitting size. This stops blockages and keeps your system working well.

Tip: Write down everything your system needs before you buy hydraulic hose fittings. This list will help you choose the best one.

Measure and Match Components

You must measure your hose and fittings very carefully. Good measurements help you stop leaks, bursts, and wasted energy. Use a tape measure or calliper to check the inside, outside, and length of your hydraulic hose.

| Reason | Explanation |

|---|---|

| Efficiency | The right hose size lets fluid move well and keeps pressure steady. If the inside is too small, pressure drops too much. |

| Safety | Hoses that are too big or small can break, causing leaks or bursts. This can hurt people or damage things. |

| Compatibility | Good measurements make sure the hose fits with other parts. This stops leaks or hoses coming loose at the fittings. |

Check that your hydraulic couplers and fittings are the same size as your hose. If you use the wrong size, your system might break.

Check Standards and Compatibility

Always check if your hose and fittings follow world standards. These rules make sure your parts fit and keep your system safe.

| Standard | Description |

|---|---|

| ISO | International rules for hydraulic fittings, like metric cone and thread, O-ring face seal, and JIC 37-degree flare. |

| SAE | Society of Automotive Engineers rules for hydraulic fittings in machines and factories, like SAE J514 37-degree flare and SAE J517 hydraulic hose. |

| JIS | Japan Industrial Standards for hydraulic fittings, like JIS B2351 bite-type and JIS B8363 hose couplings. |

Look at the product labels or ask the seller about these rules. If you follow them, you will not have leaks or bad performance.

Note: Always check the maker’s details with what your system needs. This helps you pick the right hydraulic hose fittings.

Use Selection Tools

You can use special tools to help you pick the right hose. These tools make it easier and more correct. One tool is the Flow Capacity Nomogram. This chart helps you find the right hose size for how much fluid you need to move and how fast.

| Source | Description |

|---|---|

| Selecting the Proper Hose for Your Application | Tells you how to pick hose size using Flow Capacity Nomograms for flow rate. |

| The S.T.A.M.P. Checklist for Hydraulic Hose Selection | Shows how to use flow-sizing nomograms to get the right inside size for flow rate and speed. |

| Hydraulic Hose Flow Rate: The Ultimate Guide 2025 | Says makers give flow capacity charts to help you pick hose size for flow rate and pressure. |

| How to Use the Nomographic Chart to Size Your Hydraulic & Industrial Hoses | Explains how these charts help you pick the best hose size for fluid flow and speed. |

You can find these charts online or in catalogues. Use them to match your system’s flow rate with the hose size you need. This helps you stop pressure drops and keeps your system working well.

Remember: Learning to pick the right hydraulic hose takes time. Use all the tools and guides you can to make the best choice.

If you follow these steps, you will know how to pick the right hose for your machine. Your system will be safe, work well, and last longer.

Common Mistakes to Avoid

Picking the right hose fittings helps keep your system safe. It also makes your machine work well. You can stop many problems if you know what mistakes to look for.

Wrong Pressure or Size

You need to match the pressure rating and size. Your hydraulic hose must fit your system. If you choose the wrong size or pressure, leaks can happen. Hoses might burst or crack. Hydraulic systems work at certain pressures. If pressure gets too high, hoses and fittings can break. The seal size changes the cylinder and groove size. Using the wrong size lowers fluid flow. Parts wear out faster when this happens.

Always check the pressure and size before you put in new hose fittings. This easy step helps you avoid expensive repairs.

Incompatible Materials

Material choice is important for safety and how long things last. If you use materials that do not match, you may get leaks. Sudden failures or chemical reactions can also happen. Parts that do not match need more fixing. Mixing different metals can cause galvanic corrosion. This damages seals and fittings. Pressure problems also make important parts wear out sooner.

- Always check that your hose fittings match the fluid and the place you use them.

- Do not mix metals unless you are sure they will not react.

Incorrect Thread Type

Thread type changes how well hydraulic couplers seal and stay strong. If you pick the wrong thread, you might see leaks. Pressure can drop or the system can fail. Threads that do not match can bend or break. Small leaks from bad sealing lower system pressure over time. Using too much force on wrong threads can be dangerous.

- Always find out the thread type before you join fittings.

- Use the right amount of force to keep parts safe.

Overlooking Application Needs

You need to think about how and where you use your machine. If you forget about pressure, fluid, or the environment, fittings can break early. Not thinking about system design makes your machine work worse. You will need more repairs.

Make a checklist of what your machine needs before you buy new hydraulic hose or couplers.

Here is a table that shows common mistakes and what can happen:

| Mistake | Consequence |

|---|---|

| Neglecting environmental and chemical resistance | Fittings fail early, causing leaks and poor system work. |

| Avoiding regular maintenance and inspection | Damage goes unnoticed, leading to leaks and big failures. |

| Poor installation practices | Leaks at joins and early wear, making things unsafe and costing more to fix. |

| Overlooking system compatibility | Fittings fail early, more repairs needed, and possible danger. |

When to Seek Expert Advice

Picking hydraulic hose fittings looks easy at first. But sometimes you need help from an expert. You want your machines to work safely and well. If your system is tricky or has special needs, do not guess. Getting it wrong can cause leaks, breakdowns, or hurt people.

Complex Applications

Some machines use lots of hoses and fittings. Some systems have high pressure or move fluids fast. In these cases, every detail must be correct. Experts know how to match fittings to your system. They help you stop problems like hose bursts or pressure drops. Ask for help if your machine uses advanced controls or works in hard places.

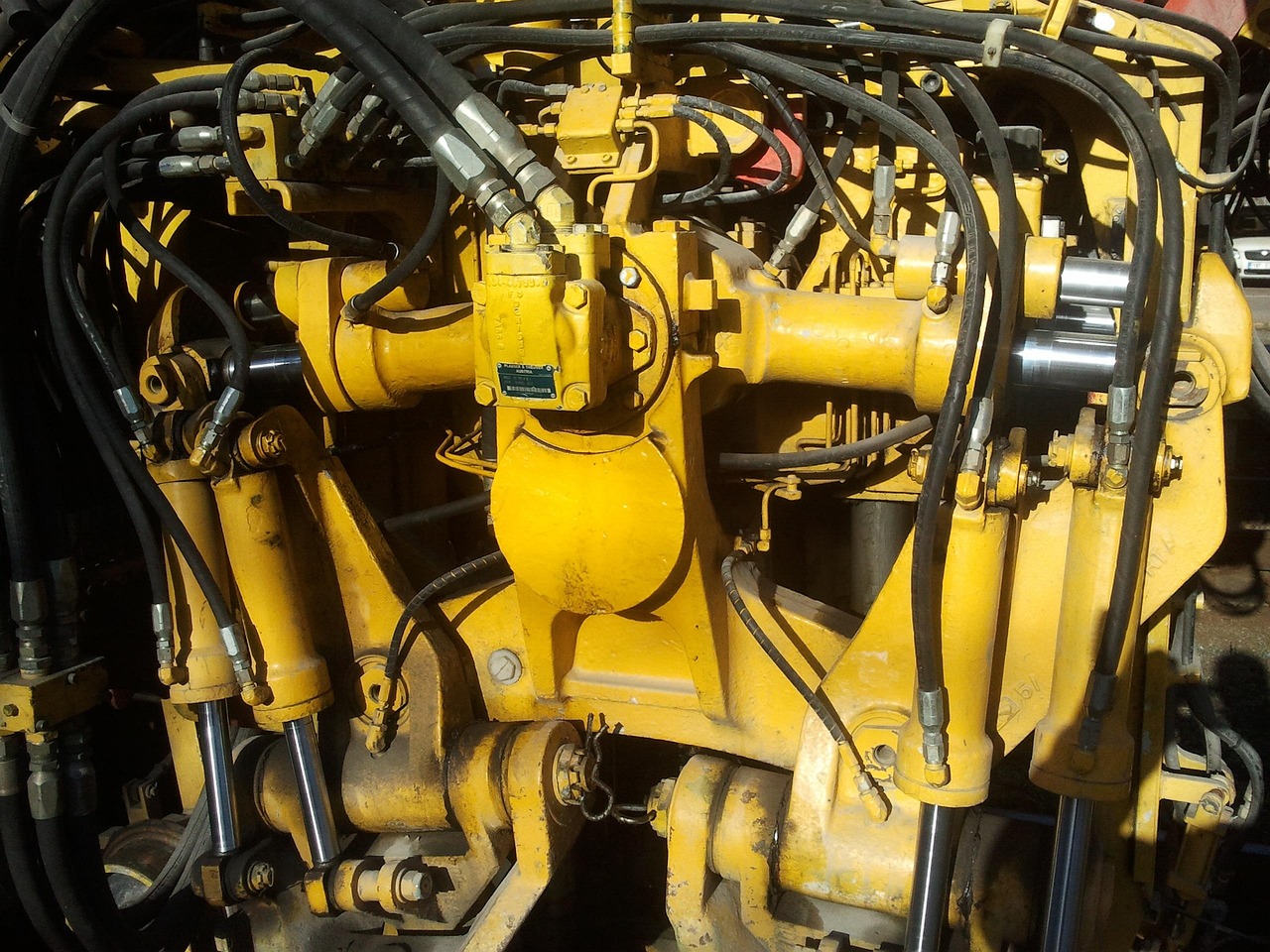

If you see many hoses, valves, or hydraulic couplers, expert advice helps you pick the safest fittings.

Unusual Requirements

Sometimes, your machine needs something different. You might use fluids that react with metals. You might work in places with lots of dust or water. You may need fittings that do not rust or fit in small spaces. Experts know which materials work best in tough places. They help you choose fittings that last longer and keep your system safe.

- High-pressure jobs need fittings that do not break.

- Corrosive places need special materials.

- Unique systems need special solutions.

Uncertainty About Standards

You may not know which rules fit your machine. Different countries and jobs use different rules. If you are not sure, talk to a professional. Experts know the latest rules and check if your fittings are safe. They help you avoid mistakes and keep your system legal.

| Scenario | Why Expert Advice Matters |

|---|---|

| High-pressure systems | Stops dangerous failures |

| Corrosive environments | Makes sure materials match |

| Special operational needs | Finds fittings for special jobs |

| Unclear standards | Checks safety and rules |

If you feel unsure, expert advice helps you feel safe and protects your money.

You can keep your machines safe if you follow simple steps. Pick hydraulic hose fittings that match the pressure, size, and material your system needs. Always check if the fittings work with your machine and meet the right standards. Look at your hoses often to find damage or leaks early. Doing regular checks and changing old hoses helps them last longer.

| Maintenance Activity | Purpose |

|---|---|

| Regular inspections | Find damage before it gets worse |

| Routine checks | Stop sudden problems from happening |

| Timely replacements | Make hoses work for more years |

Make checking your hoses a habit. Acting early keeps your machines safe and helps them work well for a long time.

FAQ

What is the difference between permanent and reusable hydraulic hose fittings?

Permanent fittings need special tools to attach. You cannot remove them once installed. Reusable fittings screw on by hand. You can remove and use them again. Choose permanent fittings for long-term use. Pick reusable fittings for quick repairs.

How do you know which thread type to use?

You must check the thread shape and size. Look at the fitting and compare it to a chart. Use a thread gauge if you have one. Always match the thread type to your hose and machine.

Can you mix different materials for hose fittings?

You should not mix different metals unless you know they will not react. Mixing metals can cause corrosion. This weakens the fitting and may cause leaks. Always check with the manufacturer before mixing materials.

How often should you inspect hydraulic hose fittings?

You should check your fittings every month. Look for leaks, cracks, or rust. Early checks help you find problems before they get worse. Regular inspection keeps your system safe and working well.

What happens if you use the wrong size fitting?

Using the wrong size fitting can cause leaks or bursts. The hose may not seal properly. This can damage your machine and stop work. Always measure carefully and match the fitting size to your hose.