10 Leading Hose Fitting Supply Companies Across America

You seek reliable hose fitting supply partners to support demanding projects in engineering, agriculture, mining, and industrial equipment. The North American industrial hose market continues to expand, driven by robust demand and advancements in hydraulic technology.

- The U.S. hydraulic hose fittings market is projected to reach USD 8.2 billion by 2033, up from USD 5.8 billion in 2024, with a 4.5% CAGR.

You must evaluate those companies based on reputation, product range, innovation, and customer service. Choosing a suitable manufacturer like Novafit Hydraulic ensures you receive solutions that match your technical requirements and operational standards.

Selecting the Right Hydraulic Fitting Supplier

- Evaluate suppliers based on reputation, product range, innovation, and customer service to ensure reliable hydraulic solutions.

- Prioritize suppliers with proven experience and compliance with industry standards for quality assurance and safety.

- Look for manufacturers that offer a wide selection of hydraulic fittings tailored to your specific operational needs.

- Choose suppliers who invest in technological advancements, such as smart sensor technology and custom solutions, to enhance efficiency.

- Ensure strong after-sales support from suppliers to maintain uptime and optimize the performance of your hydraulic systems.

Supplier Selection Criteria

Choosing the right supplier for hose fittings in the North American industrial hose market requires a strategic approach. You must evaluate suppliers based on several critical factors to ensure your hydraulic solutions meet the demands of engineering machinery, agricultural equipment, mining operations, and industrial systems.

Reputation & Experience

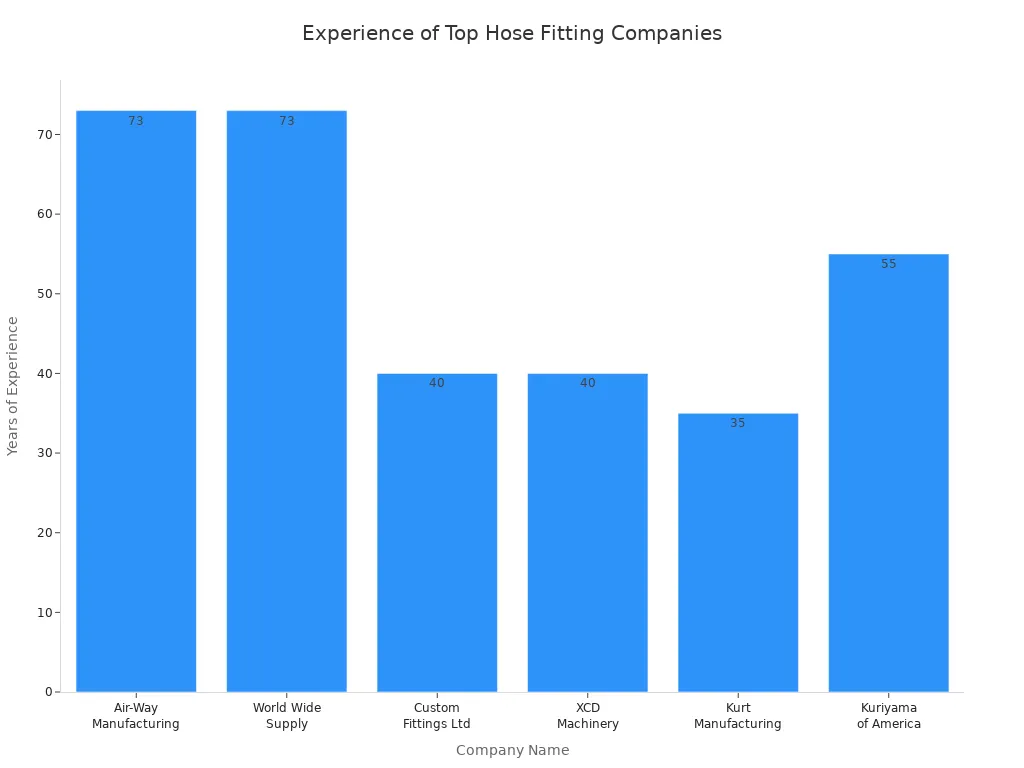

You should prioritize suppliers with a proven track record in delivering quality products and reliable hydraulic solutions. Years of experience often reflect a supplier’s ability to adapt to market changes and maintain high standards. The following chart compares the experience of leading suppliers in the industry:

A supplier’s reputation is shaped by technological innovation, compliance with regulations, competitive pricing, and responsiveness to global economic trends.

| Key Factor | Description |

|---|---|

| Technological Innovation | Advances in materials science enhance durability and performance, improving precision and reducing costs. |

| Regulatory Environment | Compliance with safety and environmental standards is essential for market acceptance. |

| Pricing Trends | Fluctuations in raw material costs affect pricing strategies and procurement planning. |

| Global Economic Influence | Economic growth in emerging markets increases demand, while mature economies focus on maintenance. |

Product Range & Specialization

You need suppliers that offer a comprehensive selection of hose fittings and hydraulic solutions. The main product categories include:

- Garden Hose Quick Connect Fittings

- Brass Hose Fittings

- Plastic Hose Fittings

- Camlock Fittings

- Push-On Hose Fittings

Specialized suppliers focus on hydraulic fittings and high-pressure hose fittings, which are essential for heavy-duty applications.

| Supplier Name | Specialization | Location | Website |

|---|---|---|---|

| Hy-Lok | Leak-free connections for instrumentation, pneumatics, hydraulics, and fluid delivery systems. | Houston, TX, USA | hylokusa.com |

| Manuli | High-quality hydraulic hose fittings with over 6,000 references. | Bologna, Italy; Warrendale, PA, USA | manuli-hydraulics.com |

| Intertraco | Components for hydraulic power transmission, including fluid connectors and fittings. | Suzzara, Italy | intertraco.it |

| Novafit Hydraulics | Precision hydraulic fittings and fluid-connection solutions for various applications. | Yuyao, Zhejiang, China | www.novafit-hydraulic.com/ |

Innovation & Technology

You benefit from suppliers who invest in technological advancements. Recent innovations include:

| Innovation Type | Description |

|---|---|

| 3D Printing | Revolutionizes design and manufacturing, allowing rapid prototyping and customization. |

| Tailored Solutions | Custom hoses designed to meet specific requirements, enhancing performance in unique applications. |

| Fire-Resistant Hoses | New materials withstand extreme temperatures, crucial for hazardous environments. |

| Non-Conductive Hoses | Developed for electrical safety, preventing electrical conductivity in hazardous applications. |

| Smart Sensor Technology | Integration of smart technology to enhance operational efficiency and monitoring capabilities. |

Suppliers who offer tailored hydraulic solutions and smart sensor technology help you optimize safety and efficiency in your operations.

Service & Support

Customer support is a key differentiator among suppliers. You should look for suppliers who provide:

| Type of Service | Description |

|---|---|

| Customization | Tailoring products to meet specific requirements, especially for various industrial applications. |

| Technical Support | Providing expert assistance and guidance on hose testing, certification, and assembly processes. |

| Proactive Asset Management | Identifying and managing high-risk assets to prevent failures and ensure operational safety. |

Responsive customer support ensures you receive technical guidance and rapid solutions for your hydraulic solutions. Suppliers who excel in service help you maintain uptime and reduce operational risks.

Tip: When comparing suppliers for hydraulic fittings and high pressure hose fitting needs, assess their product range, quality certifications, ability to serve your sector, and commitment to customer support.

You can use these criteria to select suppliers who deliver quality, reliability, and innovation for your hydraulic solutions.

Top Hose Fitting Supply Companies

When you evaluate hose fitting supply partners for your business, you need to consider manufacturers that deliver reliability, innovation, and scalability. The following profiles highlight the leading hose companies in the north america industrial hose market, focusing on their strengths in hydraulic fittings, high pressure hose fitting solutions, and industrial hose products. These manufacturers serve large-scale buyers in engineering machinery, agricultural machinery, mining equipment, and industrial equipment.

Novafit

Novafit stands out as a global leader in hydraulic hose fittings and adapters. You benefit from their advanced manufacturing capabilities, including cold forming, cold forging, and hot forging technologies. Novafit operates a 40,000m² smart factory equipped with over 2,000 CNC machines, ensuring precision and efficiency in every product. Their annual output reaches 80 million hydraulic fittings and 2 million hose assemblies, supporting large orders and custom requests.

| Product Category | Unique Strengths |

|---|---|

| Hydraulic Manufacturing | Innovative design, high quality, wide range, quick response |

| Cold Forming | High material utilization, high-strength products, high-efficiency production, precision control |

| Hot Forging | Strong forming ability, improved material properties, economical and efficient |

| Cold Forging | Enhanced strength, excellent dimensional accuracy, high production efficiency |

| Precision Machining | High-precision machining solutions, super capacity matrix, automatic machining scene |

Novafit offers a broad selection of hydraulic hose fittings, including JIC, BSP, NPT, SAE, and Metric types. You can rely on their ISO 9001, ISO 14001, and CE certifications for consistent quality. Their independent R&D and design teams deliver customized solutions for demanding hydraulic applications. Novafit’s transparent procurement process and global reach make them a preferred partner for B2B clients seeking high-quality products and trouble-free service.

You gain a competitive edge by partnering with Novafit, a manufacturer that combines innovation, capacity, and international standards.

Eaton Corporation

Eaton Corporation is a powerhouse in hose fitting supply, offering a wide range of hydraulic fittings, adapters, and accessories. You benefit from their intelligent power management solutions and commitment to sustainability. Eaton’s advanced manufacturing capabilities and global reach support complex hydraulic projects across multiple sectors.

| Key Products | Company Profile |

|---|---|

| Hose fittings | Eaton is dedicated to improving quality of life and protecting the environment. |

| Hydraulic adapters | They focus on sustainable operations and power management. |

| Hydraulic accessories | Eaton helps customers transition to renewable energy and address urgent power challenges. |

Eaton employs generative AI to accelerate product design and system integration. You can expect cost-efficient, high-performance hydraulic hose fittings and high-pressure hose fitting solutions. Their training and education programs help your team stay ahead in fluid-handling technology.

- Advanced materials for enhanced performance

- System integration for fluid-handling solutions

- Environmental sustainability focus

- Global distribution and support

Parker Hannifin

Parker Hannifin is a trusted name among hose fitting supply manufacturers. You access a diversified product portfolio that covers hydraulic fittings, pneumatic actuators, filtration systems, fluid connectors, and electromechanical systems. Parker’s strong research and development capabilities drive innovation in hydraulic hose fittings and high-pressure hose fitting products.

| Product Category | Examples of Products |

|---|---|

| Hydraulics | Hydraulic pumps, cylinders |

| Pneumatics | Pneumatic actuators, valves |

| Filtration Systems | Air and liquid filtration systems |

| Fluid Connectors | Hoses, fittings |

| Electromechanical Systems | Electric motors, drives |

Parker Hannifin’s global presence and strategic acquisitions ensure you receive high-quality products and technical support wherever your operations are located.

- Diversified product portfolio

- Strong R&D capabilities

- Global reach

- Strategic growth through acquisitions

Gates Corporation

Gates Corporation is a leading manufacturer in the industrial hose market, recognized for its extensive range of hydraulic fittings and high-pressure hose fitting solutions. You can source products for automotive, industrial, infrastructure, and consumer applications.

| Product Categories | Industry Focus |

|---|---|

| Automotive | Power transmission |

| Industrial | Fluid power solutions |

| Infrastructure | Agriculture, mining, and more |

| Consumer Products | Everyday life solutions |

Gates invests in research and development to improve product durability and performance. Their global distribution network ensures you receive hydraulic hose fittings and industrial hose products quickly and reliably.

- Wide range of hoses for various applications

- Strong reputation and brand recognition

- Commitment to product improvement

- Extensive global reach

Dixon Valve & Coupling

Dixon Valve & Coupling delivers high-quality products for hose fitting supply, specializing in hydraulic fittings, camlock fittings, and sanitary solutions. You benefit from their durable machined components, corrosion-resistant materials, and compliance with safety standards.

| Feature | Description |

|---|---|

| Material | Brass, strong and corrosion-resistant |

| Heat Resistance | Superior to aluminum fittings |

| Connection Type | Secure hose grip with raised ridges |

| Certification | Safe Drinking Water Act compliance for potable and non-potable water |

Dixon’s hygienic fittings serve the food, beverage, pharmaceutical, and biotech industries. Their easy-to-operate handles and smooth surfaces prevent bacteria buildup, supporting your safety and quality requirements.

- Machined components from solid steel bar stock

- Stainless steel retaining rings and springs for corrosion resistance

- ROHS Compliant Zinc Nickel plating for durability

You can trust Dixon for excellence and customer satisfaction in demanding industrial hose applications.

Kuriyama of America

Kuriyama of America specializes in industrial hose and accessories, focusing on thermoplastic, rubber, and metal hose products. You can source couplings and fittings designed for a wide range of industrial and commercial applications.

| Product Type | Specialization |

|---|---|

| Industrial Hoses | Thermoplastic, Rubber, Metal Hose |

| Accessories | Couplings and Fittings for Applications |

Kuriyama’s comprehensive product range supports your operations in agriculture, mining, and heavy industry. Their expertise in industrial hose solutions ensures you receive reliable and efficient products for your hydraulic systems.

NovaFlex Group

NovaFlex Group offers a broad spectrum of hose fitting supply products, including hydraulic fittings, high pressure hose fitting solutions, and specialty hoses for diverse industries. You can select from air, chemical, food and beverage, marine, mining, petroleum, and custom connectors.

| Product Category |

|---|

| Air and Compressed Gas |

| Chemical |

| Food and Beverage |

| High Temperature |

| Marine General Purpose |

| Marine Sanitation |

| Marine Water & Exhaust |

| Marine Fuel |

| Material Handling |

| Mining |

| Petroleum |

| PVC, Urethane and Thermoplastic |

| Specialty |

| Sweeper & Vacuum Truck |

| Water & Steam |

| Water Hose – Fire Engine Suction |

| Custom Connectors/Expansion Joints |

| Biodiesel and Ethanol Service |

| Liquefied Petroleum Gas (LPG) Composite Hose |

| Roof Drain Hose |

| HDC® Couplers |

NovaFlex’s custom solutions and expansion joints help you address unique challenges in industrial hose applications. Their focus on specialty products supports your operational flexibility and safety.

TitanFittings

TitanFittings is a manufacturer and distributor of hydraulic fittings, hydraulic hose fittings, tube fittings, and accessories. You benefit from their ISO 9001:2015 certification, which guarantees consistent quality and customer satisfaction.

| Strengths | Description |

|---|---|

| Quality | Highest quality components, including hoses and stainless fittings across hydraulic categories |

| Service | Experienced personnel, quick order processing, and shipping capabilities |

| Availability | Over 50,000 parts in stock, 2 distribution centers, 2-day shipping anywhere |

TitanFittings serves energy production, chemical manufacturing, biopharm, food and beverage, and marine industries. Their large inventory and fast shipping help you minimize downtime and keep your hydraulic systems running smoothly.

- Hydraulic adapters and hose fittings

- Tube fittings and accessories

- Quick response and technical support

Brennan Industries

Brennan Industries is a manufacturer specializing in hydraulic fittings, adapters, valves, and accessories. You can choose from over 120,000 fitting styles, backed by aerospace-quality manufacturing and full traceability.

| Product Categories | Strengths |

|---|---|

| Hydraulic Fittings and Adapters | Strong emphasis on quality, availability, and support |

| Accessories and Components | Extensive product range, more than competitors |

| Engineered Specials and Built-to-Print | Aerospace quality manufacturing, full traceability |

| Global Distribution | 15 distribution centers worldwide |

| Educational Materials | Blogs, whitepapers, and tools for thread identification and CAD |

| E-commerce System | Live inventory information, proprietary coatings for durability |

Brennan’s global distribution network and e-commerce system provide you with real-time inventory and technical resources. Their proprietary coatings enhance product durability, supporting your hydraulic systems in demanding environments.

When you select from these top hose fitting supply manufacturers, you ensure your business receives reliable hydraulic fittings, high pressure hose fitting solutions, and industrial hose products tailored for large-scale operations.

Hydraulic Fittings & High-Pressure Hose Overview

Hydraulic Fittings Types

You encounter a wide range of hydraulic fittings in industrial environments. Manufacturers design these fittings to connect hydraulic hoses, tubes, and pipes, ensuring leak-free performance in high-pressure equipment. Selecting the right hydraulic fittings impacts the reliability of your hydraulic systems. The table below highlights the most common types of hydraulic fittings used in large-scale operations:

| Type of Fitting | Description | Key Advantages | Common Applications |

|---|---|---|---|

| Pipe Fittings | Threaded connections (NPT, BSPT) for creating seals. | Cost-effective, available in various materials. | General hydraulic systems. |

| Compression Fittings | Uses a compression ring to create a seal. | Compact, easy to install, adaptable to different materials. | Connecting hoses in hydraulic systems. |

| Flare Fittings | Specialized compression fittings with a flared end for high-pressure systems. | Creates powerful seals, minimal maintenance required. | Industrial and mobile hydraulic equipment. |

| O-Ring Fittings | Utilizes a flexible ring to create a seal. | Leak-resistant, absorbs vibrations, suitable for high-pressure applications. | Machinery subjected to shock and vibration. |

You rely on precision hydraulic fittings to maintain system integrity. Hydraulic hose fittings, high-pressure hose adaptors, and high-pressure fittings play a critical role in supporting high-pressure hose assemblies and high-pressure pumps.

High-Pressure Hose Fitting Applications

High-pressure hose fitting solutions serve essential functions in demanding sectors. You use hydraulic fittings and high-pressure hose in environments where durability and safety matter most. The table below outlines key applications for high-pressure hose fitting in major industries:

| Sector | Application Description |

|---|---|

| Industrial Machinery | Used in construction, mining, and manufacturing for heavy machinery like cranes and presses |

| Automotive Systems | Integral in hydraulic systems for braking and power steering in vehicles |

| Aerospace Industry | Used for aircraft control surfaces, landing gear, and braking systems |

| Agricultural Equipment | Found in tractors and harvesters to provide durability and resistance to corrosion |

| Marine Applications | Used in steering, stabilizing, and lifting operations, resistant to saltwater corrosion |

| Chemical Processing Plants | Essential for handling corrosive chemicals safely in high-pressure environments |

| Oil and Gas Industry | Required in drilling, pipelines, and refineries, capable of withstanding extreme pressures |

| Power Generation | Used in hydroelectric, nuclear, and thermal power plants for controlling turbines |

You depend on high-pressure hose, hydraulic hose fittings, and high pressure valves to keep your high pressure equipment running efficiently. Manufacturers supply high-quality products made from high-quality materials to meet the rigorous demands of industrial hose systems.

Tip: Always match your hydraulic hoses and fittings to the specific requirements of your high pressure equipment. This ensures safety and maximizes operational uptime.

Industry Standards & Certifications

You must verify that hydraulic fittings and high-pressure hose fitting products meet recognized industry standards. Leading manufacturers comply with strict certification requirements to guarantee performance and safety. Look for the following standards and certifications:

- SAE, ISO, DIN, and other industry standards for hydraulic fittings and high-pressure hose.

- Certification for dimensional accuracy, material traceability, and testing practices such as pressure testing and tensile strength.

- Documented certification and batch traceability for regulated or safety-critical systems in aerospace, medical, and energy sectors.

You protect your operations by sourcing hydraulic hose fittings and high pressure hose from manufacturers who prioritize compliance and quality assurance.

Strengths & Differentiators

Quality Assurance

You demand consistent quality from your hydraulic fittings and high-pressure hose suppliers. Leading manufacturers invest in advanced inspection systems and rigorous testing protocols. You see this commitment in their ISO certifications and adherence to industry standards. Manufacturers use automated measurement tools to check fittings for dimensional accuracy. They also perform pressure and leak tests on hydraulic hoses and industrial hose assemblies. You benefit from traceability programs that track products from raw material to finished fittings. This approach ensures that every batch of hydraulic products meets your operational requirements. Quality assurance gives you confidence in the reliability of fittings and hoses for your critical equipment.

Distribution & Logistics

You need fast and reliable delivery of hydraulic fittings, high pressure hose, and related products. Top manufacturers operate extensive distribution networks across North America. You gain access to regional warehouses and fulfillment centers that stock a wide range of hydraulic hoses, fittings, and industrial hose products. These networks support next-day or two-day delivery for urgent orders. Manufacturers use advanced logistics software to optimize inventory and track shipments in real time. You receive live updates on your orders, which helps you plan maintenance and minimize downtime. Efficient distribution ensures that your hydraulic systems stay operational, even in remote mining or agricultural locations.

Custom Solutions

Your projects often require custom hydraulic fittings and high-pressure hose assemblies. Leading manufacturers offer engineering support and design services tailored to your specifications. You collaborate with technical teams to develop fittings for unique hydraulic applications in mining equipment, agricultural machinery, or industrial hose systems. Manufacturers use CAD modeling and rapid prototyping to create custom products quickly. You can request special materials, coatings, or connection types to match your operational environment. Custom solutions help you solve complex challenges and improve the performance of your hydraulic hoses and fittings. This flexibility sets top manufacturers apart in the B2B market.

Tip: Partner with manufacturers who combine quality, logistics, and customization. You will maximize uptime and efficiency for your hydraulic equipment.

Hose Fitting Supply Comparison

Comparison Table

Selecting the right supplier for hydraulic fittings and high-pressure hose fittings can transform your operations. You need a partner who delivers consistent quality, understands your industry, and supports your technical requirements. The following table compares leading hose fitting supply companies across America. You can quickly assess each supplier’s strengths in hydraulic fittings, high-pressure hose, certifications, service, and industry focus.

| Company | Product Range | Certifications | Service Focus | Industry Focus |

|---|---|---|---|---|

| Gates Corporation | Hydraulic and industrial hoses | Extensive R&D capabilities | High-performance solutions | Heavy industry, high-pressure |

| Parker Hannifin | High-performance hoses | Innovation emphasis | Tailored configurations | Various applications |

| Eaton Corporation | Versatile hoses | Integrated safety features | Competitive pricing | Industrial |

| Manuli Hydraulics | Advanced hydraulic hoses | High-pressure applications focus | Robust solutions | Heavy industry |

| Kuriyama of America | Wide range of industrial hoses | Safety standards | Quality assurance | Various industries |

| NovaFlex Group | Specialized hoses | FDA compliance | Chemical resistance | Food and chemical processing |

| Dixon Valve & Coupling | Machined and sanitary fittings | Safe Drinking Water Act compliance | Customer satisfaction | Food, beverage, biotech |

| TitanFittings | Hydraulic adapters and hose fittings | ISO 9001:2015 | Fast shipping, technical support | Energy, marine, chemical |

| Novafit Hydraulic | Hydraulic fittings, industrial hose | IATF16949:2016, ISO 9001:2015 Quality Management, ISO 14001:2015 Environmental Management | Technical expertise, logistics | Industrial, mining, agriculture |

| Brennan Industries | Hydraulic fittings, adapters | Aerospace-quality manufacturing | Full traceability, e-commerce | Engineering, mining, industrial |

You see that Gates Corporation and Manuli Hydraulics excel in high pressure hose fitting for heavy industry. Parker Hannifin and Eaton Corporation offer broad hydraulic solutions for various applications. Kuriyama of America and NovaFlex Group focus on specialized hoses and quality assurance, supporting industrial and food processing sectors. Dixon Valve & Coupling and TitanFittings provide sanitary and hydraulic fittings with strong certifications. Novafit Hydraulic and Brennan Industries stand out for distribution, logistics, and technical support, which is vital for large-scale engineering, mining, and agricultural operations.

Tip: Use this comparison to match your hydraulic fittings and high pressure hose fitting needs with the supplier who best aligns with your sector and operational goals. You gain reliability, quality, and efficiency by choosing a partner who understands your industry.

You can leverage this table to streamline your procurement process. Evaluate each supplier’s product range, certifications, and service focus. You ensure your hydraulic systems run smoothly and meet the demands of high-pressure hose environments. The right choice supports your business in engineering machinery, agricultural machinery, mining equipment, and industrial equipment.

Choosing the Right Supplier

Assessing Application Needs

You must start by identifying the specific requirements of your operation. Consider the type of machinery, the working environment, and the pressure ratings needed for your hydraulic systems. For example, mining equipment often demands fittings that withstand extreme pressure and abrasive conditions. Agricultural machinery may require corrosion-resistant components for exposure to fertilizers and moisture. Industrial equipment in manufacturing plants benefits from fittings that support high-frequency cycles and rapid maintenance. Create a checklist of your technical specifications, including material compatibility, size range, and compliance with industry standards. This approach helps you narrow down suppliers who can deliver products tailored to your sector.

Tip: Engage your engineering team to review operational data and forecast future needs. This proactive step ensures you select hose fittings that support both current and upcoming projects.

Evaluating Capabilities

You should evaluate each supplier’s ability to meet your volume, customization, and quality requirements. Review their manufacturing technologies, such as CNC machining or advanced forging, which impact product precision and durability. Assess their certifications, like ISO 9001 or CE, to confirm adherence to global standards. Large B2B clients benefit from suppliers with robust R&D departments and flexible production lines. Ask about lead times, scalability, and the supplier’s experience with similar projects in your industry.

| Capability | Why It Matters for B2B Clients |

|---|---|

| Production Capacity | Supports large orders and rapid turnaround |

| Custom Engineering | Delivers solutions for unique applications |

| Quality Assurance | Reduces risk and ensures reliability |

| Industry Experience | Provides insight into sector-specific needs |

After-Sales Support

You need reliable after-sales support to maintain uptime and minimize disruptions. Leading suppliers offer technical assistance, training, and rapid response for replacement parts. Look for partners who provide asset management services and proactive maintenance recommendations. Responsive support teams help you troubleshoot issues and optimize system performance. For large-scale operations, after-sales service can include on-site visits, remote diagnostics, and access to digital resources.

- Technical support for installation and troubleshooting

- Training programs for your maintenance staff

- Fast delivery of spare parts and replacements

- Ongoing consultation for system upgrades

Note: Strong after-sales support strengthens your long-term partnership and protects your investment in hydraulic solutions.

You secure reliability and performance for your industrial operations when you select from these top hose fitting supply companies. Each supplier delivers high pressure hose solutions that meet the demands of engineering machinery, agricultural machinery, mining equipment, and industrial equipment. You benefit from ISO 9001:2015 certified partners who focus on quality and provide high pressure hose products with quick turnaround times. Many clients praise the service, noting, “Service is top notch” and “Great people! Will do whatever they can to help you out!”

- Next steps for B2B buyers:

- Request on-time quotes for high-pressure hose assemblies.

- Consult application engineering support for your high-pressure hose needs.

- Build partnerships with suppliers known for high pressure hose quality.

You can use the comparison table and selection criteria to make informed decisions. Choose a supplier who values quality and understands your high-pressure hose requirements.

FAQ

What factors should you consider when selecting a high-pressure hose supplier?

You should evaluate supplier certifications, production capacity, and the ability to deliver high-pressure hose solutions for demanding environments. Consider their experience with engineering machinery, mining equipment, and industrial systems. Reliable after-sales support and technical expertise also play a key role in supplier selection.

How do you ensure compatibility between high-pressure hose fittings and your equipment?

You must match the specifications of your high pressure hose fittings with your machinery’s requirements. Review pressure ratings, material compatibility, and connection types. Consult supplier technical teams to confirm that the high pressure hose assemblies integrate seamlessly with your hydraulic systems.

What maintenance practices extend the life of high-pressure hose assemblies?

You should schedule regular inspections for wear, leaks, and abrasion. Replace high-pressure hose assemblies at the first sign of damage. Use protective sleeves and proper routing to reduce stress. Training your maintenance staff ensures safe handling and maximizes the service life of each high-pressure hose.

Which certifications matter most for high-pressure hose products in industrial applications?

You should look for ISO, SAE, and CE certifications. These standards confirm that your high-pressure hose products meet global safety and quality requirements. Certifications also ensure traceability and compliance for critical applications in mining, agriculture, and heavy industry.

How can you minimize downtime when replacing high-pressure hose assemblies?

You can keep critical high pressure hose assemblies in stock and partner with suppliers who offer rapid delivery. Use quick-connect fittings for faster installation. Establish a preventive maintenance schedule to identify issues early and reduce unplanned downtime in your industrial operations.