Common faults of hydraulic adapters and their prevention methods

Table of Contents

Hydraulic adapters encounter frequent faults in industrial fluid systems. You may face issues such as fluid leakage, cracking, improper sizing, contamination, overheating, incorrect insertion depth, wear, corrosion, thread damage, seal leakage, and pressure fatigue. Problems like over-tightening, cross-threading, incompatible materials, corrosion from environmental factors, manufacturing defects, and overpressure can cause premature hydraulic system failure. The table below shows how these failures impact downtime and costs:

| Evidence Type | Details |

|---|---|

| Downtime Cost | About $20 per minute when the equipment stops during work hours. |

| Production Loss | Around $1,200 per hour is lost in forestry operations. |

| Unplanned Downtime | Hydraulic hose failures cause 37% of unplanned downtime. |

Selecting hydraulic adapters correctly and maintaining compatibility with brands like Novafit hydraulic helps you avoid costly downtime. You will find actionable tips and best practices for prevention throughout this guide.

Hydraulic Adapter Best Practices for Reliable System Performance

- Select the right hydraulic adapters to ensure compatibility and prevent costly downtime. Use precise measurements and reference technical documentation.

- Regular maintenance and inspections are crucial. Check for wear, corrosion, and leaks to catch issues early and extend equipment life.

- Monitor operating temperatures to prevent overheating. Use sensors for real-time tracking and set alerts for temperature spikes.

- Choose high-quality materials for hydraulic adapters. Ensure they are compatible with your hydraulic fluid to avoid degradation and failures.

- Follow proper installation practices to prevent leaks and mechanical damage. Always adhere to manufacturer guidelines for secure connections.

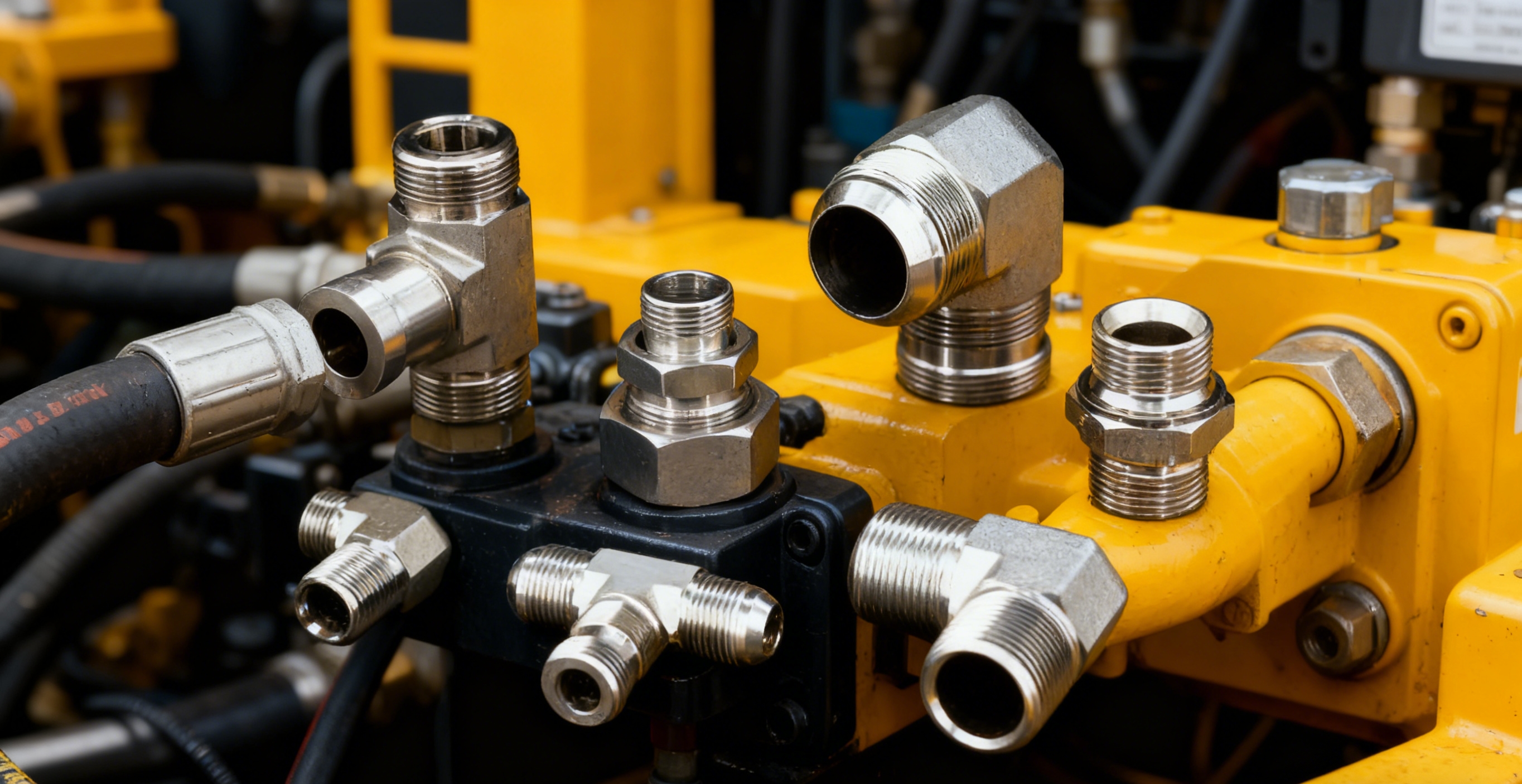

Hydraulic adapters in fluid systems

What are hydraulic adapters?

You use hydraulic adapters to connect different components in hydraulic systems. These adapters play a vital role in ensuring compatibility between pipes, hoses, and equipment. When you select the right hydraulic adapters, you simplify installation and improve system flexibility. The table below highlights how hydraulic adapters contribute to system performance:

| Functionality | Contribution to System Performance |

|---|---|

| Connection | Ensures compatibility between different equipment and pipelines, simplifying installation and enhancing system flexibility. |

| Efficiency | Optimizes fluid transmission paths, reducing pressure and energy loss, thus improving overall system efficiency. |

| Safety | Provides firm and sealed connections to prevent leaks and failures, enhancing operator and equipment safety. |

| Maintenance and Upgrades | Facilitates easy replacement and upgrades of components, reducing time and costs associated with maintenance. |

| Adaptability | Offers diverse designs to meet various application needs, expanding the scope of hydraulic systems. |

| Stability | Enhances system stability by providing stable connections that mitigate the effects of vibration and shock. |

Why reliability matters

Reliable hydraulic adapters protect your equipment and prevent costly downtime. You must consider several characteristics when selecting adapters for industrial applications. The table below outlines key features that define a dependable hydraulic adapter:

| Characteristic | Description |

|---|---|

| Fluid Compatibility | Ensure the adapter material is chemically resistant to the hydraulic fluid. |

| Material Selection | Options include stainless steel for corrosive environments, carbon steel for cost-effectiveness, aluminum for lightweight applications, and specialized alloys for extreme conditions. |

| Thread Type and Dimensional Accuracy | Match thread specifications to existing components and ensure precise machining to prevent leaks. |

| Connection Type and Application | Different types of adapters serve specific applications, such as quick-connect for mobile equipment and flange adapters for high-pressure systems. |

| Environmental and Operational Factors | Consider corrosion resistance, vibration resistance, and weight restrictions based on application needs. |

Choosing adapters with these features helps you maintain system integrity and avoid hydraulic system failure.

Novafit Hydraulic Overview

When you select a reputable brand like Novafit Hydraulic, you gain access to high-quality adapters that enhance reliability and longevity. They provide precision-engineered connectors designed for demanding environments. The brand’s products undergo rigorous hydrostatic pressure and leakage testing to ensure safety. You benefit from strong technical support and comprehensive after-sales service that guides you from design to installation. Using Novafit hydraulic adapters reduces the risk of leaks and failures, helping you maintain optimal performance in your hydraulic systems.

Common hydraulic adapter failure types

Hydraulic adapters play a crucial role in maintaining the integrity of hydraulic systems. You must recognize the most common failure modes to prevent hydraulic system failures and costly downtime. Each failure mode presents unique risks and warning signs.

Fluid leakage

Fluid leakage is the most visible sign of hydraulic adapter failure. You may notice hydraulic fluid pooling around connections or dripping from fittings. Leaks often result from damaged seals, improper installation, or worn adapter surfaces. When fluid escapes, system pressure drops, leading to reduced performance and increased risk of hydraulic pump failure. Even a small leak can contaminate the environment and create safety hazards. Using high-quality adapters reduces the risk of leaks and helps maintain system reliability.

Cracking

Cracking in hydraulic adapters can cause sudden hydraulic system failure. You should watch for fine lines or fractures on the adapter surface. Cracks develop due to several factors:

- External cover abrasion from contact with other components

- Improper bend radius that stresses the adapter

- Excessive heat exposure, which makes materials brittle

- Improper assembly or installation, such as incorrect crimping

- Fluid incompatibility, where chemicals attack the adapter from within

- Age-related deterioration that weakens the structure over time

Cracks compromise the pressure-bearing capacity of the adapter and may lead to catastrophic failure if not addressed promptly.

Wear and corrosion

Wear and corrosion degrade the material integrity of hydraulic adapters, increasing the risk of hydraulic system failures. You should inspect adapters for visible rust, pitting, thinning, discoloration, and leaks around fittings. Common signs include:

- Rust, which weakens the adapter and signals corrosion

- Pitting, creating cavities that can cause leaks

- Thinning of material, reducing pressure resistance

- Leaking fittings, with visible hydraulic fluid around connections

- Corrosion appearing as rust or powdery residue

Adapters exposed to harsh environments or incompatible fluids are more likely to suffer from wear and corrosion. Choosing corrosion-resistant materials and following maintenance schedules can help you avoid hydraulic cylinder failure.

Thread damage

Thread damage is a frequent cause of hydraulic adapter failure. You may encounter stripped, cross-threaded, or uneven threads during installation or maintenance. Damaged threads prevent secure connections and increase the risk of leaks. Over-tightening, contamination, or repeated assembly can accelerate thread wear. When threads fail, you lose the ability to maintain proper pressure and system stability. Selecting adapters with precise machining, such as those from Novafit Hydraulic, helps you avoid thread-related issues.

Seal leakage

Seal leakage allows contaminants to enter hydraulic systems, leading to decreased efficiency and potential system failure. You should monitor for fluid escaping around seals and inspect for signs of contamination. According to industry statistics,

It is a statistical fact that 80% of machine and equipment stoppages and component failures are caused by contaminated lubricants. Many of these contaminated fluids are a direct result of fluid leaks from hydraulic machinery.

Seal leakage can cause wear and damage to internal components, reduce system performance, and create fire risks when hydraulic fluids contact hot surfaces. You must address seal issues quickly to prevent hydraulic system failure and maintain safety.

Pressure fatigue

Pressure fatigue occurs when hydraulic adapters experience repeated or excessive pressure cycles. You should look for the following indicators:

| Sign of Material Fatigue | Description | Causes and Implications |

|---|---|---|

| Discoloration | Color changes on the adapter | Weakening from heat or chemicals |

| Loose or Misaligned Fittings | Movement or wobbling | Improper installation, vibration, or impacts |

| Wear Marks and Abrasion | Scratches or grooves | Friction or abrasive contaminants |

| Leaking Fittings | Fluid around fittings | Worn seals or cracks, leading to leaks and safety hazards |

| Visible Cracks and Fractures | Fine lines or breaks | Excessive pressure or repeated stress |

| Corrosion and Rust | Rust or powdery residue | Weakens structure, causes leaks |

| Deformation and Warping | Bent or distorted fittings | Excessive stress or impacts |

| Worn or Damaged Threads | Stripped or uneven threads | Over-tightening or contamination |

| Unusual Noises | Hissing or grinding sounds | Leaks or internal wear |

Adapters that show these signs may fail under pressure, resulting in hydraulic system failure. You should select adapters rated for your system’s operating pressure and inspect them regularly to prevent fatigue-related issues.

By understanding these common hydraulic adapter failure types, you can take proactive steps to protect your hydraulic systems. Using reliable products following best practices for installation and maintenance will help you avoid costly failures and downtime.

Causes of hydraulic adapter failure

Hydraulic adapters face several common causes that can lead to hydraulic system failure and costly downtime. You must understand these causes to prevent equipment failure and maintain compatibility in your hydraulic systems.

Improper sizing

Improper sizing is one of the most common causes of hydraulic system failure. When you select adapters that do not match your system requirements, you risk turbulence in fluid flow, pressure drops, and decreased efficiency. Oversized fittings create turbulence, while undersized fittings restrict flow and cause overheating. Loose fittings can result in leaks and hazardous conditions. Pressure loss and increased wear on hoses and pumps often occur due to mismatched fittings, which can lead to hydraulic pump failure or even catastrophic failure.

- Turbulence in fluid flow reduces efficiency.

- Restricted flow from undersized fittings causes overheating.

- Loose fittings create leaks and hazardous conditions.

- Pressure loss affects component performance.

- Increased wear leads to frequent repairs.

- Severe sizing errors may cause catastrophic failures.

Selecting hydraulic adapters with the correct size is essential for preventing these issues.

Material compatibility issues

Material compatibility is critical for reliable hydraulic systems. If you use adapters made from incompatible materials, you risk chemical compatibility problems and mismatch issues. Corrosion, wear, and premature failure can result from poor material selection. Always consider the hydraulic fluid type and environmental conditions when selecting hydraulic adapters. Novafit hydraulic offers adapters designed for optimal compatibility, reducing the risk of hydraulic cylinder failure.

Pressure rating errors

Pressure rating errors are a leading cause of hydraulic adapter failure. You must ensure that each adapter meets industry standards for pressure ratings. Proof tests require adapters to withstand at least twice the maximum working pressure, while burst tests demand four times the maximum pressure. Failure to meet these standards exposes components to unsafe conditions and increases the risk of hydraulic valve failure.

| Aspect | Description |

|---|---|

| Pressure Rating Errors | Expose components to pressures beyond their rated capacity, leading to failure. |

| Importance of Standards | Industry standards ensure consistent and safe pressure ratings. |

| Testing Methods | Proof tests (2x working pressure) and burst tests (4x working pressure) verify safety and reliability. |

Correct pressure ratings help you avoid hydraulic system failures and maximize operational uptime.

Contamination

Contamination is a frequent cause of hydraulic hose and fitting failures. Air contamination results in foamy fluid and reduced efficiency. Water contamination leads to corrosion and sludge, impairing lubrication. Chemical contamination occurs as hydraulic fluid degrades. Ingressed contamination, such as sand and dirt, enters during maintenance. Particulate contamination circulates debris that damages system components. Hydraulic fluid contamination can originate from production, fluid transfer, storage, manufacturing, or service activities. You must control contamination to prevent signs of hydraulic system failure.

Overheating

Overheating impacts the structural integrity of hydraulic adapters. When temperatures exceed 180°F (82°C), seals may harden or crack, causing leaks and pressure loss. Prolonged overheating damages precision components and degrades hydraulic oil. You should monitor operating temperatures to prevent hydraulic system failures and maintain compatibility.

Incorrect insertion depth

Incorrect insertion depth compromises connections and can result in hose blow-off, posing safety hazards. You must ensure proper insertion during assembly and follow guidelines to avoid failure. Regular training helps maintain secure connections and prevents hydraulic system failure.

Wear, corrosion, thread damage, seal leakage, and pressure fatigue also contribute to hydraulic adapter failure. Wear and corrosion arise from harsh environments and incompatible fluids. Thread damage results from over-tightening or contamination. Seal leakage allows contaminants to enter, while pressure fatigue develops from repeated stress cycles. Addressing these causes helps you avoid common causes of hydraulic system failure and maintain reliable performance with Novafit hydraulic adapters.

Prevention methods for hydraulic adapter failure

You can prevent hydraulic adapter failure by implementing targeted measures at every stage of system design, installation, and operation. These proactive measures for hydraulic system maintenance will help you avoid hydraulic system failure, reduce downtime, and extend the life of your equipment.

Correct sizing and selection

Selecting the right hydraulic adapters is the foundation of a reliable system. You must evaluate system requirements, including pressure rating, material, and compatibility, to ensure optimal performance. The following table summarizes best practices for sizing and selection:

| Best Practice | Description |

|---|---|

| Evaluate system requirements | Assess factors like material, pressure rating, and compatibility to meet system demands. |

| Proper installation practices | Follow manufacturer guidelines to avoid over-tightening or misalignment, which can lead to failures. |

| Regular maintenance | Establish a schedule for inspections to catch wear and tear before it escalates into major issues. |

You should always consult manufacturer guidelines, such as those provided by Novafit Hydraulic, to match adapters with your system’s specifications. Using high-quality counterparts ensures that you minimize the risk of failure and maintain system integrity.

Tip: Never guess adapter size. Use precise measurements and reference technical documentation to avoid costly mistakes.

Ensuring material compatibility

Material compatibility plays a critical role in preventing premature failure. You need to select adapters made from appropriate materials and coatings to withstand your hydraulic fluid and operating environment. Consider the following measures:

- Choose quality products with suitable materials and protective coatings.

- Verify that all materials are compatible with the hydraulic fluid to avoid degradation.

- Use components from the same product line to enhance reliability and reduce the risk of failure.

- Check material compatibility to prevent degradation and prolong system life.

Regular maintenance and inspection

Routine maintenance and inspection are essential measures to detect early signs of failure. You should create a tailored inspection schedule based on your operating conditions. Increase inspection frequency for high-pressure or extreme temperature environments. Follow these steps:

- Conduct regular inspections to identify visible damage such as cracks, corrosion, or deformation.

- Pay special attention to connection points, which are prone to stress.

- Use a flashlight to check hard-to-reach areas for leaks.

- Document findings to track wear patterns and plan replacements.

- Look for signs of wear like discoloration, pitting, or rust, which indicate material degradation.

- Listen for unusual noises during operation, as they may signal leaks.

Preventive maintenance helps you catch problems before they escalate, reducing the risk of hydraulic system failure.

Note: Always keep detailed records of inspections and repairs. This practice supports long-term reliability and helps you plan future measures.

Proper installation practices

Correct installation prevents leaks and mechanical damage. You must follow manufacturer guidelines and use the right tools. The following ordered steps outline effective installation practices:

- Hydraulic Power-Off: Isolate the system from its energy source.

- Depressurization: Open bleed valves or use pressure relief mechanisms.

- Verify Zero Pressure: Check with gauges—never assume a system is depressurized.

- Align the Flange Faces: Use alignment tools to ensure no misalignment.

- Insert and Center the Gasket or O-ring: Ensure proper placement to avoid uneven compression.

- Torque in Multiple Passes: Use a calibrated torque wrench and follow a specific sequence to ensure even pressure distribution.

- Avoid Common Mistakes: Be aware of over-tightening and under-tightening to prevent leaks.

You should always reference manufacturer guidelines, such as those from Novafit Hydraulic, to ensure proper installation and minimize the risk of failure.

Using clean fluids and filtration

Contamination is a leading cause of hydraulic adapter failure. You must use high-quality, clean hydraulic fluids designed for your machinery. Implementing proper filtration systems is one of the most effective measures to prevent contamination. Consider these steps:

- Use fluids that meet your hydraulic system’s specifications and are free from impurities.

- Install and maintain filtration systems to remove solid particles and prevent slime accumulation.

- Replace filters regularly to maintain fluid cleanliness.

- Monitor fluid condition and schedule periodic fluid analysis.

At least 75% of all hydraulic systems fail due to aging or contaminated hydraulic fluid. Contaminated fluid causes degradation, increases internal leakage, and lowers the efficiency of motors, cylinders, and pumps. By maintaining clean fluids, you reduce the risk of failure and protect your hydraulic adapters.

Alert: Solid particles can erode valve interiors and cause operational failures. Always prioritize fluid cleanliness as part of your preventive measures.

Monitoring operating temperatures

Overheating can lead to adapter failure and hydraulic system failure. You need to monitor operating temperatures to ensure safe and efficient performance. Use the following measures:

- Install temperature sensors to track fluid and component temperatures.

- Use flow meters to detect blockages or inefficiencies that could cause overheating.

- Employ real-time temperature sensors for continuous monitoring and early detection of anomalies.

- Consider advanced tools like the SensoNODE Blue Temperature Sensor, which transmits data wirelessly and provides alerts for temperature fluctuations.

Monitoring hydraulic pressure and temperature helps you identify problems before they fail. Novafit hydraulic adapters are designed to withstand demanding conditions, but you must still implement these measures to maintain system reliability.

Tip: Set up automated alerts for temperature spikes. Early intervention prevents costly damage and supports long-term system health.

By following these measures, you can significantly reduce the risk of hydraulic adapter failure. Implementing proactive measures for hydraulic system maintenance, referencing manufacturer guidelines, and choosing high-quality counterparts will help you maintain compatibility and ensure reliable operation.

Best practices for selecting hydraulic adapters

Selecting hydraulic adapters for your fluid system requires a structured approach. You must focus on compatibility, maintenance, and proper training to ensure reliable operation and prevent costly failures. Following industry standards and manufacturer guidelines helps you achieve optimal performance.

Compatibility checklist

You need to verify several criteria before installing hydraulic adapters. A compatibility checklist ensures that each component matches your system’s requirements. Review the table below to guide your selection process:

| Criteria | Description |

|---|---|

| Media Compatibility | Confirm the adapter can handle the specific hydraulic fluid in your system. |

| Working Pressure | Ensure the adapter withstands the maximum system pressure. |

| Abrasion Resistance | Select adapters designed for environments with high wear and tear. |

| Temperature Resistance | Choose adapters that perform well under your application’s temperature conditions. |

| Application-Specific Standards | Verify compliance with relevant certifications and safety standards. |

You should also consider pressure rating, vibration resistance, and application-specific design. These factors help you maintain secure seals and prevent leaks, especially in demanding environments.

Maintenance schedule

A structured maintenance schedule extends the life of your hydraulic adapters and reduces the risk of unexpected downtime. You should follow these best practices:

- Inspect adapters regularly for signs of wear, corrosion, or leaks.

- Replace worn or damaged components promptly to prevent system failure.

- Adjust maintenance intervals based on your operating conditions and experiences.

- Refer to OEM datasheets for specific instructions and service intervals.

For piston pumps, a service interval of 10,000 hours is generally recommended. Prioritizing maintenance helps you avoid costly repairs and keeps your hydraulic system running smoothly.

Training and documentation

Proper training and documentation support safe and effective use of hydraulic adapters. You should invest in comprehensive training programs that cover the basics of hydraulics, safe operation, system maintenance, and troubleshooting. Both beginners and experienced operators benefit from ongoing education.

Key steps for installation and maintenance include:

- Select the appropriate fitting for your application.

- Cut and prepare the hose correctly.

- Crimp or assemble the fitting according to manufacturer guidelines.

- Conduct a visual inspection to check for damage or misalignment.

- Install protective caps and test the connection for leaks.

Maintaining accurate records of inspections and repairs improves reliability and supports future decision-making. By following these best practices, you ensure compatibility and long-term performance when selecting hydraulic adapters for your system.

You can prevent hydraulic adapter failure by focusing on proactive maintenance, correct selection, and compatibility. Regular inspections and proper installation help you catch issues early and extend equipment life. Choosing quality brands like Novafit hydraulic ensures reliable performance in demanding environments.

Tip: Use a checklist for ongoing prevention:

- Daily fluid level and leak checks

- Weekly system performance analysis

- Monthly hose and fitting service

- Quarterly reliability assessment

FAQ

What causes hydraulic adapter leaks?

You often see leaks from damaged seals, improper installation, or worn surfaces. Always select hydraulic adapters with proven sealing technology to reduce leak risks.

Tip: Inspect connections regularly to catch leaks early.

How do you choose the right hydraulic adapter size?

You must measure your hose and fitting dimensions accurately. Reference manufacturer charts and technical documentation.

- Use calipers for precise measurement

- Confirm pressure rating and compatibility

Selecting hydraulic adapters with the correct sizing prevents system failure.

Why is material compatibility important for hydraulic adapters?

Material compatibility protects your system from corrosion and chemical damage. You should match adapter materials to your hydraulic fluid and environment.

| Adapter Material | Best Use Case |

|---|---|

| Stainless Steel | Corrosive fluids |

| Carbon Steel | General applications |

| Aluminum | Lightweight systems |

How often should you inspect hydraulic adapters?

You need to inspect adapters monthly for signs of wear, corrosion, or leaks. Increase inspection frequency in high-pressure or harsh environments.

What are the benefits of using Novafit hydraulic adapters?

Novafit hydraulic adapters offer precision engineering, rigorous testing, and strong technical support. You gain reliable performance, reduced downtime, and enhanced safety.

- Leak prevention

- High-pressure resistance

- Compatibility with various fluids