What Global Buyers Should Consider When Comparing Hydraulic Adapter Manufacturers in Asia?

Table of Contents

When you compare hydraulic adapter manufacturers in Asia, you need to focus on several key factors that impact performance and reliability. The table below highlights the most common criteria global buyers use to evaluate leading hydraulic adapter manufacturers:

| Factor | Description |

|---|---|

| Quality Certifications | Shows commitment to quality and compliance with global standards. |

| Experience and Reputation | Reflects reliability built through years in the hydraulic industry. |

| Customer References | Offers real-world insights into strengths and weaknesses. |

| Product Quality | Ensures hydraulic adapters deliver consistent performance. |

| Materials and Processes | Impacts the durability and reliability of hydraulic solutions. |

| Testing and Traceability | Guarantees safety through rigorous hydraulic testing. |

| Customer Service | Provides ongoing support after sourcing hydraulic adapters. |

Selecting the right manufacturer ensures quality, reliability, and strong support for your hydraulic systems. Brands like Novafit hydraulic adapter have built a reputation for excellence in sourcing and delivering high-performance hydraulic solutions.

Key Factors Buyers Should Evaluate When Choosing Hydraulic Adapter Manufacturers

- Focus on quality certifications like ISO 9001 to ensure reliable and safe hydraulic adapters.

- Evaluate the manufacturer’s experience and reputation to gauge their reliability in the hydraulic industry.

- Request detailed material specifications to assess product quality and compatibility with your systems.

- Consider delivery reliability and lead times to avoid project delays and maintain operational efficiency.

- Look for transparent pricing structures to avoid hidden costs and ensure value for your investment.

Quality Standards for Hydraulic Adapter Manufacturers

When you compare hydraulic adapter manufacturers in Asia, you must focus on quality standards. These standards determine the performance, reliability, and safety of your hydraulic systems. Leading manufacturers invest in quality certifications, advanced engineering, and rigorous quality control to deliver high-quality products. Novafit hydraulic adapter stands out as a comprehensive source for hydraulic adapters, known for engineering excellence and strict adherence to international standards.

Material Selection

Material selection plays a critical role in the durability and performance of hydraulic adapters. You should assess product quality by examining the materials used by hydraulic fitting manufacturers. The right material ensures safety and reliability in high-performance fluid transfer systems.

Tip: Always request detailed material specifications from your supplier to assess product quality and ensure compatibility with your engineering requirements.

Here is a comparison of commonly used materials and their impact on performance and durability:

| Material | Properties | Impact on Durability and Performance |

|---|---|---|

| Stainless Steel | Strength, corrosion resistance | Excellent for high-pressure, corrosive environments |

| Carbon Steel | High strength, moderate corrosion resistance | Ideal for heavy-duty applications |

| Aluminum | Lightweight, robust, corrosion-resistant | Suitable for aerospace and mobile equipment |

| Brass | Corrosion-resistant, low vibration | Best for HVAC and light machinery |

| Polyurethane | Enhanced durability, wear resistance | High durability in demanding conditions |

| Rubber | Flexibility, shock absorption | Good for flexible applications |

| Specialized Alloys | Withstand extreme temperatures and pressures | Used in aerospace and subsea oil rigs |

You will find that steel and stainless steel adapters offer the highest reliability for demanding hydraulic applications. Aluminium provides weight savings for mobile equipment, while brass works well in low-pressure systems. Polyurethane and rubber components add flexibility and shock absorption, enhancing overall system performance.

ISO Certifications

ISO certifications serve as a benchmark for quality and reliability among hydraulic adapter manufacturers. You should always verify the quality certifications held by your supplier. These certifications demonstrate a commitment to engineering excellence and consistent product quality.

| ISO Certification | Description |

|---|---|

| ISO 9001 | Recognises dedication to quality management systems, ensuring consistent products that meet regulatory requirements. |

| ISO 14001 | Highlights commitment to environmental management, striving to reduce environmental impact and promote sustainability. |

| ISO 45001 | Underscores focus on occupational health and safety, emphasising the importance of creating safe work environments for all employees. |

Manufacturers with ISO certifications, such as Novafit hydraulic adapter, deliver high-quality products that meet international standards. ISO 9001 certification, in particular, assures you of rigorous quality control and reliable performance. When you choose a supplier with these certifications, you gain confidence in the safety and reliability of your hydraulic systems.

Quality Control

Rigorous quality control processes ensure that every hydraulic adapter meets strict engineering and performance standards. You should assess product quality by reviewing the manufacturer’s quality control procedures. Leading hydraulic adapter manufacturers in Asia implement advanced inspection systems and maintain quality certifications to guarantee consistent results.

| Quality Control Process | Description |

|---|---|

| Thorough Quality Review | Every product undergoes a quality review before packaging and shipping. |

| Inspections at Every Stage | Checks include material surface, hardness, dimensions, and threads. |

| Advanced Tools Usage | Utilises CMM, 3D measurement systems, and thread gauges for inspections. |

| Consistent High Quality | All threads, dimensions, and surface treatments meet strict standards. |

| Specialisation in Stainless Steel | Focus on stainless steel for higher precision and better quality control. |

| Strong After-Sales Support | Free replacement or credit for defective products. |

You benefit from high-performance engineering support when you select manufacturers with robust quality control systems. These processes help prevent defects, reduce downtime, and ensure the long-term performance of your hydraulic equipment. Novafit hydraulic adapter exemplifies this commitment by maintaining comprehensive quality certifications and offering reliable after-sales support.

Capacity and Lead Times

When you evaluate hydraulic adapter manufacturers in Asia, you must consider both capacity and lead times. These factors directly impact your ability to maintain a steady supply and meet project deadlines. Leading hydraulic adapter manufacturers in Asia invest in advanced engineering and large-scale production facilities to deliver consistent performance and reliable delivery.

Scalability

Scalability determines how well a manufacturer can handle changing order volumes. You need a partner who can ramp up production quickly for large projects or urgent requirements. Many top hydraulic adapter manufacturers in Asia operate expansive factories and use dedicated production lines for both standard and custom hydraulic fittings. For example, Letone produces 30 million meters of hydraulic hoses and industrial hoses annually, with plans to quadruple this output as its industrial park reaches full capacity. They also manufacture 25,000 tons of rubber compounds and 20 million rubber seals per year, with future projections set even higher.

You can see how leading manufacturers support scalability in the table below:

| Feature | Description |

|---|---|

| Factory Area | Exceeds 10,000 m² |

| Dedicated Production Lines | Separate lines for standard and custom fittings |

| Automated Inventory Management | Efficient order handling and tracking |

| Example Manufacturer | Ningbo Ningji Yuli with a 30,000+ m² plant |

| Workforce | Over 170 employees for flexible scaling |

This level of scalability ensures you receive consistent engineering support and uninterrupted hydraulic supply, even during peak demand.

Delivery Reliability

Reliable delivery schedules are essential for your project planning and operational efficiency. Top hydraulic adapter manufacturers in Asia maintain high inventory levels of popular hydraulic fittings and raw materials. This approach allows them to respond quickly to urgent orders and minimise lead times. Some manufacturers have achieved a 99.99% on-time delivery rate for three consecutive years, demonstrating a strong commitment to customer satisfaction.

Key practices that support delivery reliability include:

- Maintaining a stock of popular hydraulic adapter sizes.

- Ensuring a ready supply of essential materials for expedited production.

- Offering quick delivery times for urgent hydraulic orders.

A strict quality assurance program further guarantees that every shipment meets your performance expectations. When you choose a manufacturer with proven delivery reliability, you reduce the risk of project delays and gain confidence in your hydraulic supply chain. This reliability is a hallmark of the best hydraulic adapter manufacturers in Asia and should be a top priority in your selection process.

Pricing and Sourcing Transparency

When you evaluate hydraulic adapter manufacturers in Asia, you must prioritise pricing and sourcing transparency. Transparent pricing helps you avoid unexpected expenses and supports a strategic sourcing approach. You need clear information on every cost component to build a reliable global supplier portfolio and maintain a consistent hydraulic supply.

Price Structure

You should always request a detailed breakdown of the pricing structure from your hydraulic adapter manufacturers. Transparent pricing allows you to compare offers accurately and align your sourcing strategy with your project budget. Leading manufacturers provide clear quotes that include unit price, tooling fees, packaging, and logistics. This level of transparency ensures you understand the total cost of ownership and can make informed decisions for your hydraulic engineering needs.

Hidden Costs

Many buyers focus only on the quoted price, but hidden costs can quickly erode your savings. For example, a hydraulic adapter priced at $0.80 per piece may rise to $1.50 after adding mould fees, express shipping, customs duties, and other charges. You must analyse all potential expenses to avoid surprises in your sourcing process.

| Hidden Cost Type | Description |

|---|---|

| Minimum Order Quantities (MOQs) | Some factories require orders of 50 to 500+ units, affecting the total cost. |

| Handling Surcharge | Smaller orders may incur a 5–10% handling surcharge. |

| Lead Times | Cheaper quotes may come with long lead times; expedited options may cost more. |

| Freight and Customs Duties | Proximity to ports affects landed cost; additional shipping costs can erode savings. |

| Warranty and Support Costs | Manufacturers with better support may charge more but reduce long-term risks. |

You should also consider these common hidden costs:

- Tooling costs (mould fees)

- Logistics expenses (express shipping)

- Customs brokerage fees and import duties

- Packaging charges

- Bank transfer and currency exchange fees

- Additional tax documents for customs clearance

Tip: Always ask for a comprehensive cost estimate before finalizing your hydraulic sourcing agreement.

Value for Money

You achieve value for money by looking beyond the lowest price. Assess the quality of materials, supplier reliability, compliance with industry standards, and after-sales service. A low initial price may lead to higher long-term costs if the hydraulic adapters fail to meet performance expectations or lack proper support. Strategic sourcing means you balance pricing with quality and reliability to ensure the best outcome for your hydraulic systems.

By focusing on pricing and sourcing transparency, you strengthen your global supplier portfolio and improve the performance of your hydraulic supply chain.

After-Sales Support and Communication

When you compare hydraulic adapter manufacturers in Asia, you must look beyond product delivery. Strong after-sales support and clear communication channels set leading manufacturers apart. These factors ensure you receive ongoing assistance, maintain system reliability, and maximise the performance and support of your hydraulic equipment.

Responsiveness

You need a manufacturer who responds quickly to your questions and concerns. Fast and effective communication helps you solve technical issues, track orders, and manage your hydraulic supply chain. Leading hydraulic adapter manufacturers in Asia use multiple channels to provide support. The table below shows the most effective communication channels for after-sales support:

| Communication Channel | Importance |

|---|---|

| Phone | Ensures direct and immediate support |

| Allows for detailed communication and documentation | |

| Chat | Provides quick responses and accessibility |

You should choose a supplier who offers all these channels. This approach guarantees you can reach the support team when you need help with hydraulic engineering or urgent supply issues. Quick responses reduce downtime and improve the overall performance of your hydraulic systems.

Tip: Always test the responsiveness of a manufacturer’s support team before finalizing your order. Fast replies signal a commitment to quality and customer care.

Warranty Policies

Warranty policies protect your investment and reflect the manufacturer’s confidence in their hydraulic products. You should review the warranty terms before making a decision. For example, THM Huade Hydraulics provides a clear warranty policy that outlines the terms and conditions agreed upon at the time of purchase. This agreement helps you understand the coverage and the process for claiming support if you encounter any issues with hydraulic adapters.

Many reputable hydraulic adapter manufacturers in Asia also demonstrate their commitment to quality and reliability through certifications and industry memberships:

- Laike Hydraulics has obtained ISO9001:2000 certification.

- The company is RoHS compliant.

- Laike is a member of CHPSA and has served as the trustee of NHPSA.

These credentials show that the manufacturer values quality and offers strong after-sales support. When you select a supplier with robust warranty policies and industry recognition, you gain peace of mind and ensure long-term performance for your hydraulic systems.

Choosing a manufacturer with responsive support and clear warranty policies gives you a competitive edge. You secure reliable engineering assistance, maintain high system performance, and protect your investment in hydraulic adapters.

Reputation of Leading Hydraulic Adapter Manufacturers

When you select hydraulic adapter manufacturers in Asia, you gain significant advantages by choosing companies with a strong reputation. Leading hydraulic adapter manufacturers have proven track records in delivering quality, reliability, and consistent hydraulic supply. Their experience and customer satisfaction set them apart in a competitive market.

Industry Experience

You should always consider the years of experience a manufacturer brings to the hydraulic industry. Companies with long-standing operations have refined their engineering processes and quality control systems. They understand the demands of global hydraulic markets and can adapt to changing requirements. Leading hydraulic adapter manufacturers often invest in advanced technology and skilled teams to ensure every hydraulic product meets strict standards. This experience translates into better technical capability, faster delivery times, and improved communication efficiency.

Customer Feedback

Customer feedback gives you valuable insights into the strengths and weaknesses of hydraulic adapter manufacturers. You can evaluate quality, reliability, and service by reviewing what other buyers have experienced. The table below summarises common themes in customer feedback for hydraulic adapter manufacturers in Asia:

| Theme | Description |

|---|---|

| Quality | Customers praise the durability and reliability of products. |

| Customer Service | Responsiveness and willingness to address issues are highlighted positively. |

| Price | Some customers express concerns about higher prices compared to competitors. |

You see that quality and reliability receive the most positive attention. Customers also value responsive service, which helps resolve hydraulic supply issues quickly. However, some buyers note that prices may be higher than those of less established competitors. This feedback helps you balance cost with the assurance of dependable hydraulic performance.

Note: Always review customer testimonials and third-party reviews before making a decision. These sources reveal how manufacturers handle real-world hydraulic challenges.

References

Checking references and case studies strengthens your confidence in a manufacturer’s ability to deliver quality hydraulic solutions. Leading hydraulic adapter manufacturers provide detailed case studies that showcase their engineering expertise and successful hydraulic projects. You should request references from similar industries or applications to verify reliability and performance. This step ensures you partner with a manufacturer who can meet your specific hydraulic requirements and maintain a steady supply.

By focusing on reputation, you reduce risks and secure a reliable partner for your hydraulic systems. Leading hydraulic adapter manufacturers in Asia combine experience, positive customer feedback, and strong references to deliver the quality and reliability your projects demand.

Compliance and Documentation

When you evaluate hydraulic adapter manufacturers in Asia, you must verify their compliance and documentation capabilities. These factors play a crucial role in international sourcing and strategic sourcing decisions. Manufacturers who excel in export experience and maintain proper certifications help you avoid delays and ensure smooth customs clearance.

Export Experience

Export experience demonstrates a manufacturer’s ability to navigate complex international regulations and deliver hydraulic adapters to global markets. You should assess the breadth of their export markets and the support they offer. Manufacturers with extensive export experience provide one-stop solutions, including OEM/ODM design, custom packaging, rapid sample delivery, and full technical after-sales service. The table below highlights how leading hydraulic adapter manufacturers in Asia showcase their export expertise:

| Manufacturer | Export Markets | Key Features |

|---|---|---|

| Jiayuan | Japan, Germany, USA, UK, France, South Korea, Australia, Canada, Brazil, Russia | One-stop support, OEM/ODM design, custom packaging, rapid sample delivery, technical after-sales service |

| XCD | Europe, North America, Southeast Asia | High-quality hydraulic components, serving various industries |

| Ruihua | Europe, Asia, the Middle East, North and South America, Africa | Strict quality control systems, diverse technical capabilities |

| PEHEL | Europe, North America, the Middle East, Southeast Asia | Modern factories, advanced testing, ISO-based QC processes |

| QC Hydraulics | North America, Western Europe, Australia, Japan, Southeast Asia, the Middle East | OEM/ODM services, interchangeable products, high export percentage, responsive support |

You gain confidence in your hydraulic supply chain when you choose manufacturers with proven export experience. This expertise ensures timely delivery and compliance with destination country regulations.

Certifications

Certifications validate a manufacturer’s commitment to quality and regulatory standards. You should request documentation that proves compliance with international requirements for hydraulic adapters. The following table outlines essential documentation for exporting hydraulic adapters from Asia:

| Documentation Type | Description |

|---|---|

| ISO 9001 | Certification for quality management systems |

| CE marking | Conformity with health, safety, and environmental protection standards |

| Local Regulations | Additional certifications required by specific markets, such as the EU |

Manufacturers often hold multiple certifications to meet the demands of different industries. You should look for the following certifications when sourcing hydraulic adapters:

- ISO certifications: Indicate adherence to internationally recognised quality standards.

- Industry-specific standards: Ensure suitability for specialised applications.

- IATF 16949: Required for automotive hydraulic adapter manufacturers.

- ISO 14001: Focuses on environmental management systems.

Tip: Always request copies of certifications and export documentation before finalizing your hydraulic sourcing agreement. This step protects your investment and streamlines customs clearance.

By prioritising compliance and documentation, you minimise risks and ensure your hydraulic adapters meet global standards. This approach supports strategic sourcing and strengthens your position in the international market.

Choosing the Right Hydraulic Adapters Manufacturer

When you start choosing the right hydraulic adapters manufacturer, you must focus on how well their products fit your hydraulic systems. Compatibility ensures you avoid costly downtime and system failures. Manufacturers in Asia offer a wide range of hydraulic adapters, but you need to verify several technical details before making your decision.

Compatibility with Systems

You should check the compatibility of hydraulic adapters with your existing equipment. Mismatched fittings can lead to leaks, poor performance, and financial loss. Here are key points to consider:

- Thread type: Confirm that the thread type matches your fittings, tools, and hoses. Common thread types include NPT, BSP, SAE, and metric.

- Thread compatibility: Ensure the adapter’s threading aligns with your system to prevent leaks and failures.

- Fitting style and threading: Select the correct fitting style to avoid system breakdowns.

Tip: Request technical drawings and specifications from the manufacturer to verify compatibility before placing an order.

Pressure Ratings and Fluid Types

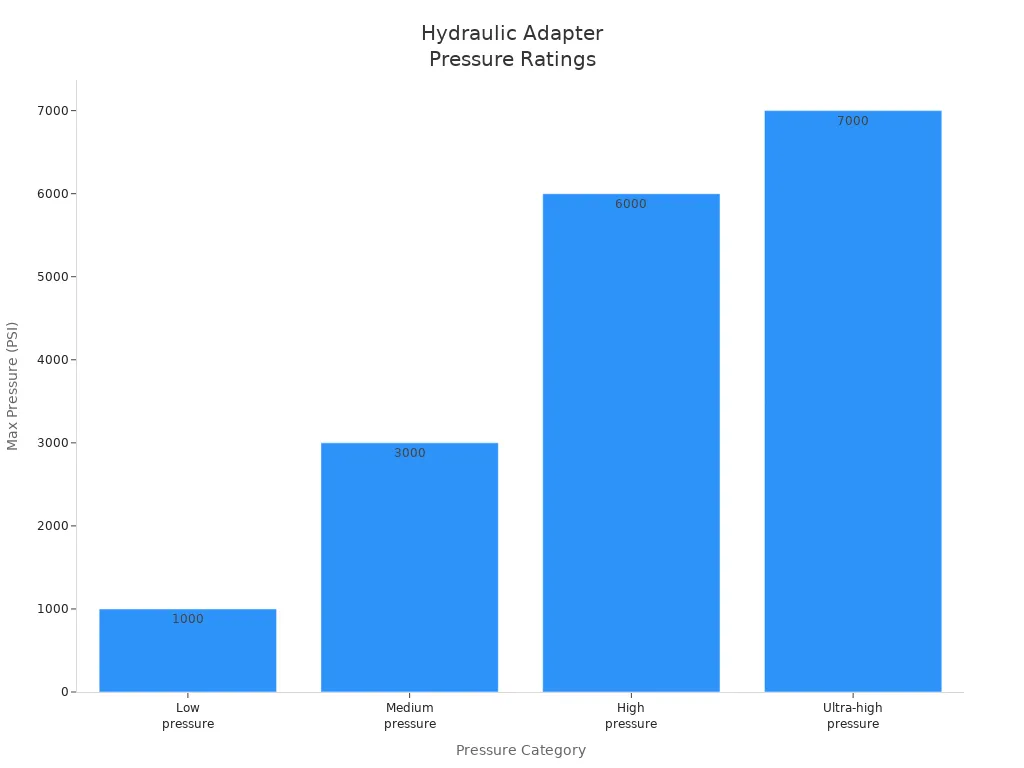

Hydraulic systems operate under different pressure ranges. You must choose adapters that meet your system’s pressure requirements. Leading hydraulic adapter manufacturers in Asia provide products for a wide spectrum of pressure categories:

| Pressure Category | Pressure Range |

|---|---|

| Low pressure | Up to 1,000 PSI (69 bar) |

| Medium pressure | 1,000-3,000 PSI (69-207 bar) |

| High pressure | 3,000-6,000 PSI (207-414 bar) |

| Ultra-high pressure | Above 6,000 PSI (414+ bar) |

You also need to confirm that the hydraulic adapters are compatible with the fluid types in your system, such as oil, water, or synthetic fluids. Manufacturers with strong engineering capabilities can provide guidance on material selection for optimal quality and performance.

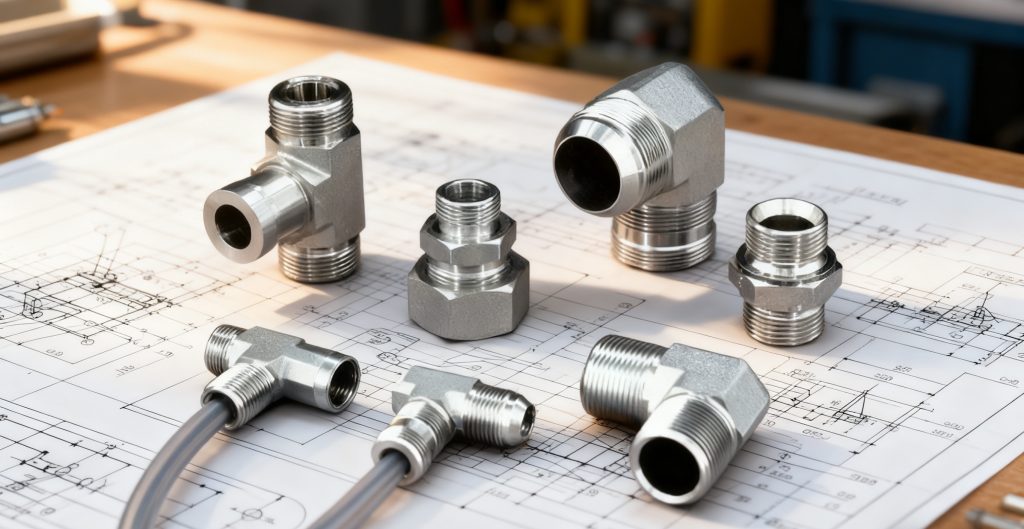

Connection Styles

Connection style affects installation speed and reliability. You should select hydraulic adapters with connection styles that match your system requirements. Common styles include straight, elbow, tee, and cross adapters. Each style serves a specific function in hydraulic engineering and impacts system layout.

- Straight adapters: Used for direct connections.

- Elbow adapters: Allow for changes in direction.

- Tee adapters: Split flow between multiple lines.

- Cross adapters: Connect four lines at a single point.

Choosing the right hydraulic adapters manufacturer means you get products that fit your system, meet pressure demands, and support your engineering goals. Manufacturers in Asia vary in price, delivery time, technical capability, and communication efficiency. Always compare these factors to ensure you receive the best hydraulic solution for your needs.

When you compare hydraulic adapter manufacturers in Asia, you should focus on quality, certifications, sourcing transparency, after-sales support, reputation, and system compatibility. Use a checklist to evaluate engineering, supply, and performance. The table below highlights essential criteria for reliability:

| Criteria | Description |

|---|---|

| Quality Assurance | Certifications like ISO 9001 and IATF 16949 ensure high standards. |

| Expertise | Proven track record and custom hydraulic solutions. |

| Cost Effectiveness | Competitive pricing with reliable hydraulic supply. |

| Support Services | Technical support and warranty coverage. |

| Reputation | Strong industry feedback and client satisfaction. |

Novafit hydraulic adapter matches industry standards for reliability and performance. You gain confidence in your hydraulic sourcing when you choose brands with strong engineering and support.

FAQ

What factors should you prioritise when comparing Hydraulic Adapter Manufacturers in Asia?

You should focus on product quality, price transparency, delivery reliability, technical capability, and communication efficiency. These criteria help you select the best hydraulic adapter manufacturer for your project needs.

How do ISO certifications impact your choice of hydraulic adapter supplier?

ISO certifications show a manufacturer’s commitment to quality and safety. You gain confidence in product reliability and international compliance when you choose certified hydraulic adapter manufacturers in Asia.

Why does delivery time matter when sourcing hydraulic adapters?

Fast delivery times reduce project delays and keep your hydraulic systems running smoothly. Leading hydraulic adapter manufacturers in Asia maintain high inventory levels and efficient logistics to support urgent orders.

What technical support should you expect from reputable hydraulic adapter manufacturers?

You should expect detailed product specifications, engineering guidance, and responsive after-sales support. Top hydraulic adapter manufacturers in Asia provide technical expertise to help you solve installation and compatibility challenges.

How can you avoid hidden costs when sourcing hydraulic adapters from Asia?

Tip: Always request a comprehensive price breakdown, including shipping, customs, and warranty fees. Transparent hydraulic adapter manufacturers in Asia help you avoid unexpected expenses and optimize your sourcing budget.