Global Hose and Fitting Supply for Construction & Mining Equipment

Table of Contents

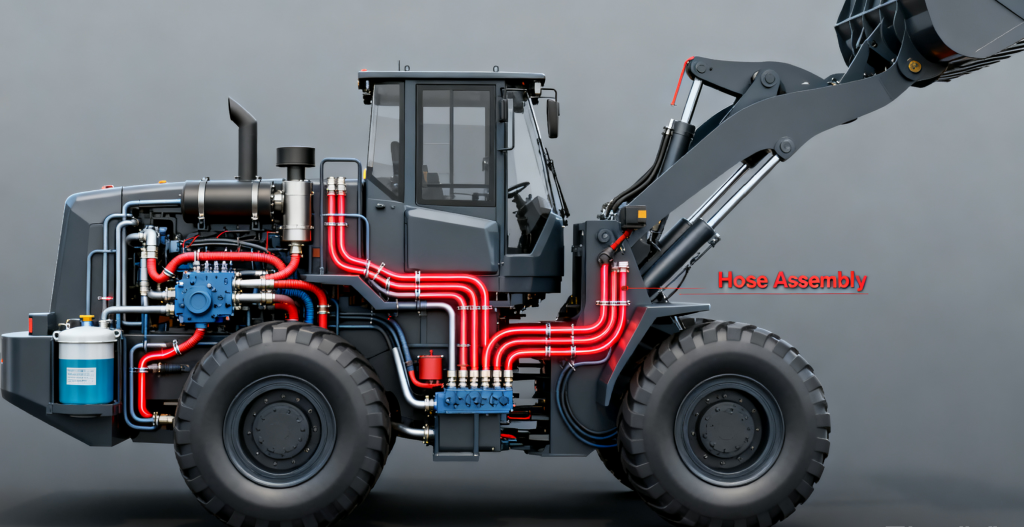

You face growing demand for reliable hose and fitting supply in construction and heavy machinery worldwide.

- Rapid industrialization in the Asia Pacific is driving demand for custom hose assemblies across excavators, loaders, and drilling machines.

- Custom hose assembly solutions restore uptime, prevent lost production, and deliver consistent performance in demanding applications.

- High-pressure hydraulic hose assemblies ensure safety, as fluid power failures account for over 10% of incidents in mining.

- Expert installation, careful material selection, and trusted brands like Novafit guarantee quality and performance for your applications.

Custom hose assembly keeps your construction operations running smoothly and protects equipment performance.

| Key Benefits of Custom Hose Assembly | Impact on Performance |

|---|---|

| Reduced downtime | Reliable power |

| Quick repairs | Enhanced safety |

| Compatibility across applications | Consistent quality |

Custom Hose Assembly: Key Insights for Boosting Performance, Reliability, and Long-Term Efficiency

- Custom hose assemblies enhance equipment performance by ensuring a precise fit and reducing downtime.

- Selecting the right materials for hydraulic hoses is crucial for durability and reliability in harsh environments.

- Regular inspections and preventive maintenance practices can significantly extend the life of hydraulic hose assemblies.

- Partnering with trusted brands like Novafit ensures access to quality products and expert support for your projects.

- Understanding pressure and temperature ratings is essential for selecting the right hydraulic hose for your equipment.

Global Supply for Construction Equipment

Bulk Hydraulic Hose Assemblies

You need reliable hydraulic hose assemblies to keep your construction and heavy machinery operating at peak performance. Bulk supply options allow you to maintain inventory and respond quickly to unexpected fluid power failures. You can choose from several types of hydraulic hose assemblies for large-scale projects:

- Rubber hoses deliver flexibility, strength, and resistance to harsh conditions.

- Thermoplastic hoses provide lightweight solutions for low-temperature or high-pressure fluid applications.

- Teflon (PTFE) hoses offer excellent chemical resistance, making them ideal for aggressive fluids.

- Stainless steel hoses withstand high temperatures and corrosion, ensuring long-term performance in extreme environments.

Custom solutions help you match the right hydraulic hose assemblies to your equipment, improving compatibility and reducing downtime. By working with bulk suppliers, you can streamline repairs and keep your operations running smoothly.

International Sourcing and Logistics

Global hose and fitting supply chains face unique challenges. You may encounter material shortages, rising costs, and transportation bottlenecks that disrupt production schedules. Tariffs and regulatory hurdles can also affect pricing and availability. Many manufacturers report unstable raw material costs and steel price fluctuations, which impact your ability to source hydraulic hose assemblies efficiently.

To overcome these obstacles, leading suppliers use real-time supply tracking and logistics software. These tools help you monitor shipments, simulate potential delays, and make informed decisions about alternative sourcing. Predictive maintenance systems alert you when to restock, supporting planned maintenance and reducing the risk of fluid power failures. Contingency planning ensures your supply chain remains resilient, even when disruptions occur.

International sourcing can also benefit you through competitive pricing and advanced quality assurance. Manufacturers in China, for example, use automated systems to test hose strength and flexibility, ensuring that hydraulic hose assemblies meet international standards. This approach delivers high performance and reliability without sacrificing quality.

Trusted Brands for Hose and Fitting Supply

Choosing the right partner for your hydraulic hose assemblies is essential for safety and performance. Trusted brands like Novafit, Gates, Eaton, and RYCO offer proven solutions for construction and mining equipment. These companies provide:

| Benefit | Description |

|---|---|

| Quality Assurance | Compliance with industry standards and rigorous testing. |

| Efficient Distribution | Fast, reliable delivery of hydraulic fittings and hoses. |

| Custom Solutions | Engineering support tailored to your operational needs. |

| Strong After-Sales Support | Robust support to protect your investment and ensure long-term performance. |

Novafit stands out for its commitment to quality and custom hose assembly solutions. By partnering with reputable brands, you gain access to expert support, advanced materials, and consistent performance for your construction projects.

Custom Hose Assembly Solutions

Custom Hydraulic Hose Assemblies for Excavators and Loaders

You rely on custom hydraulic hose assemblies to maximize the performance and reliability of your construction and heavy machinery. Custom solutions ensure that every hose fits the exact dimensions and requirements of your excavators and loaders. This precision minimizes wear and tear, reduces the risk of leaks, and extends the operational life of your equipment.

When designing custom hydraulic hose assemblies, you must consider several key factors:

- Flexibility and bend radius help you fit hoses into confined spaces and reduce stress on fittings.

- Assembly integrity guarantees leak-free connections, even under high pressure.

- Testing and validation confirm that hoses perform reliably in real-world conditions.

- Pressure rating protects your equipment from failures during peak operation.

- The temperature range maintains consistent performance across varying environments.

- Fluid compatibility ensures that hose materials resist degradation from hydraulic fluids.

Custom hoses are made to exact specifications, preventing twisting or tangling with other hoses. This reduces friction and increases lifespan. You benefit from reduced maintenance and easier replacement, improving operational efficiency. By choosing custom hydraulic hose assemblies, you address the unique challenges of your machinery and applications, ensuring optimal power delivery and safety.

High-Pressure Hose Solutions for Drilling Machines

Drilling machines in mining demand hydraulic hose assemblies that withstand extreme pressure and harsh environments. You must select hoses engineered for high-pressure applications, as these machines operate in conditions that combine abrasion, mechanical stress, humidity, and high temperatures.

Mining and drilling applications can have some of the toughest environmental and mechanical conditions that include combinations of factors such as tough abrasion and mechanical movement stress. Add to this factors such as humidity and high temperature environments along with the need for fire resistant products.

To meet these demands, you should follow these technical requirements:

- Material selection is critical. Durable hoses resist abrasion, chemicals, and extreme temperatures.

- Design considerations include reinforcement layers, wall thickness, and fitting types to withstand pressure and external forces.

- Operational requirements focus on temperature range, pressure rating, and compatibility with hydraulic fluids and mining materials.

- Specialized hoses, such as flame-resistant or static-dissipative types, help you comply with safety standards.

- Flexibility and bend radius allow hoses to accommodate equipment movement without sacrificing performance.

- Warranty and lifespan from the manufacturer assure long-term reliability.

Custom hose assembly solutions for drilling machines ensure that you maintain consistent hydraulic power and performance, even in the most demanding applications. You protect your equipment and workforce by choosing hoses designed for high-pressure environments.

Material Selection and Durability

Material selection plays a vital role in the durability and reliability of hydraulic hose assemblies. You must match the hose material to the specific requirements of your machinery and applications. Selecting the appropriate hose material based on chemical compatibility is crucial for creating effective and reliable hose assemblies. Understanding the specific requirements of the machine and environment ensures that the selected materials will withstand the operational conditions, thereby enhancing durability and reliability.

| Material Type | Impact on Durability | Impact on Reliability |

|---|---|---|

| High-Temperature Resistant | Essential for high-temperature applications | Prevents failure due to thermal stress |

| Chemical Resistant | Necessary for aggressive chemical environments | Reduces risk of degradation and leaks |

| Flexible Materials | Important for dynamic applications | Ensures performance under movement |

You can choose from several durable materials for hydraulic hose manufacturing:

| Material | Description |

|---|---|

| Stainless Steel | Used in extreme temperatures and corrosive environments, ideal for transporting aggressive fluids. |

| Nitrile Rubber | Commonly used due to compatibility with hydraulic fluids, reinforced for pressures up to 7,000 PSI. |

| Thermoplastic Polyurethane (TPU) | Constructed with a nylon tube and synthetic fiber, suitable for basic hydraulic applications. |

| Teflon (PTFE) | Offers chemical compatibility and corrosion resistance, effective in high temperatures up to 450°F. |

The choice of fitting material affects system reliability. Corrosion or damage can lead to leaks and system failures. Proper material selection minimizes maintenance and downtime, ensuring that your hydraulic hose assemblies deliver consistent performance in all applications.

You benefit from advanced options such as steel wire braided hoses for strength and pressure resistance, and spiral wire reinforced hoses for flexibility and demanding applications. By working with trusted brands like Balflex and Novafit, you gain access to custom hose assembly solutions that meet the highest standards for durability and reliability.

Custom hydraulic hose assemblies tailored to your equipment and operational needs provide superior performance, safety, and longevity. You secure the success of your construction and mining projects by investing in the right hose and fitting supply for every application.

Key Factors in Hydraulic Hose Selection

Pressure and Temperature Ratings

Selecting the right hydraulic hose for your construction equipment starts with understanding pressure and temperature ratings. You must ensure that each hose’s maximum working pressure is at least 25% higher than your system’s peak operating pressure. This safety margin protects your hydraulic hose assemblies from unexpected surges and helps maintain performance in demanding applications. Temperature also plays a critical role. Hydraulic hoses must handle both the fluid temperature and the ambient environment. For example, a hose rated for 5,000 psi at 70°F may only support 3,500 psi at 180°F. High temperatures can weaken hose materials, so always check the manufacturer’s derating guidelines. By considering these factors, you extend the life of your custom hose assembly and reduce the risk of failure in fluid power systems.

Fitting Types and Compatibility

You need to match fittings carefully to your hydraulic hose assemblies to prevent leaks and ensure reliable performance. Several fitting types are common in construction and mining applications:

- Brass fittings offer corrosion resistance and strength.

- NPT and NPTF fittings use tapered threads for secure sealing.

- ORB and ORFS fittings provide excellent leak prevention, especially in high-pressure or high-vibration environments.

- JIC and BSP fittings are widely used for their versatility and compatibility.

- Quick couplers and compression fittings allow for fast installation and maintenance.

Always confirm that the fitting size matches your hose’s inner diameter and flow requirements. Proper compatibility ensures your custom hose assembly delivers consistent performance across all applications.

Installation and Expert Tips

Proper installation of hydraulic hose assemblies is essential for safety and performance. You should:

- Replace hoses every 2-3 years or sooner if exposed to harsh environments.

- Follow manufacturer guidelines for installation and tightening torque.

- Keep hoses clean and free of debris to protect fluid quality.

- Inspect hoses and fittings regularly for wear, damage, or leaks.

- Select hoses based on fluid type, temperature, pressure, and environmental conditions.

Tip: Regular maintenance and inspection help you avoid costly downtime and keep your hose and fitting supply in top condition for all applications.

By following these expert tips, you maximize the reliability and performance of your custom hydraulic hose assemblies in every construction project.

Standards and Testing for Safety

Industry Certifications for Hydraulic Assemblies

You must rely on international standards to guarantee the safety and reliability of hydraulic hose assemblies. These certifications set strict requirements for pressure, temperature, and compatibility. When you choose a Hose and Fitting Supply partner, you should confirm that their products meet these standards. The following table shows the most recognized certifications for hydraulic hose assemblies:

| Standard | Description |

|---|---|

| SAE J517 | Provides standards for hydraulic hose assemblies, including testing requirements for pressure, temperature, and compatibility. |

| ISO 6803 | Outlines methods for testing rubber or plastic hoses under steady pressure conditions, including burst and impulse tests. |

| EN 853 & EN 854 | Specifies requirements for rubber hoses and hose assemblies, covering pressure, temperature, and electrical conductivity tests. |

You protect your equipment and workforce by selecting certified hydraulic hose assemblies. These standards help you maintain consistent fluid power and ensure your custom hose assembly performs under demanding conditions.

Testing Procedures and Quality Assurance

Rigorous testing procedures confirm the reliability of every hydraulic hose assembly. You need to verify that your custom hose assembly passes all required tests before installation. The table below highlights common testing procedures in construction and mining:

| Testing Procedure | Description |

|---|---|

| Burst Pressure Testing | Involves increasing pressure until the hose bursts to determine its maximum pressure capacity. |

| Proof Pressure Testing | Test the hose at 1.5 to 2 times its working pressure for a specified duration to check for leaks. |

| Impulse Testing | Simulates pressure cycles to assess the hose’s durability under repeated stress. |

| Leakage Testing | Checks for any leaks during pressure application to ensure the integrity of the hose. |

| Hydrostatic Pressure Testing | Verifies structural integrity by applying pressure without causing permanent damage to the hose. |

You benefit from quality assurance practices that identify weaknesses before you use the hydraulic hose assembly. These practices include:

- Impulse testing finds defects in hose construction, ensuring compliance with performance specifications.

- Performance validation checks the hose’s ability to handle pressure variations, supporting a reliable hydraulic system.

- Safety and reliability measures reduce the risk of failures, preventing machinery damage and injury.

You should always demand custom hose assembly solutions that meet or exceed these standards. By working with suppliers who prioritize quality, you secure the long-term performance of your hydraulic systems and maintain safe fluid power operations.

Troubleshooting and Maintenance

Common Issues with Hydraulic Hose Assemblies

You encounter several common issues with hydraulic hose assemblies in construction and mining equipment. Addressing these problems quickly helps you maintain safe and efficient operations. The most frequent issues include:

- Leaks: Hydraulic leaks often result from punctured hoses, loose connections, or worn seals. Leaks reduce hydraulic pressure and create safety hazards in your fluid power systems.

- Cracks and Breaks: Constant pressure and bending can cause hoses to crack or break. Extreme temperatures and repeated stress increase the risk of failure in demanding applications.

- Clogs and Blockages: Debris entering the hydraulic system can clog hoses. Blockages restrict fluid flow and negatively impact system performance.

Tip: Early detection of these issues prevents costly downtime and protects your equipment.

Preventive Maintenance Practices

You can extend the life of your hydraulic hose assemblies by following proven preventive maintenance practices. Consider these steps:

- Regular Inspections: Check hoses for wear, abrasion, and leaks.

- Proper Installation: Install hoses according to the manufacturer’s instructions to avoid kinking or twisting.

- Guard Against Abrasion: Use protective sleeves and guards to shield hoses from abrasive elements.

- Maintain Optimal Pressure: Monitor system pressure to prevent hose failure in all applications.

- Minimize Hose Movement: Secure hoses to reduce excessive flexing.

- Keep Hoses Clean: Clean hoses regularly to prevent premature wear from contaminants.

- Implement Preventive Maintenance: Create a maintenance plan with routine inspections and proactive repairs.

- Train Operators and Maintenance Personnel: Educate your team on proper hose handling and inspection techniques.

- Monitor Hose Age and Usage: Track hose age and service history for timely replacements.

A strong maintenance program ensures your custom hose assembly and Hose and Fitting Supply solutions deliver reliable performance in every application.

When to Consult a Global Supplier

You should consult a global supplier when your hydraulic hose assemblies face persistent issues or when your equipment operates in harsh environments. Mining operations require durable and reliable hydraulic solutions due to extreme conditions. Expert support ensures your assemblies meet the demands of challenging applications. Global suppliers like Gemco and Novafit offer decades of experience, strict quality control, and products recognized for reliability. Their professional teams provide installation and maintenance support, which is crucial for troubleshooting complex hydraulic systems. When you need custom hose assembly solutions tailored to your unique requirements, a global Hose and Fitting Supply partner delivers the expertise and resources you need.

You gain significant advantages by sourcing custom hose assembly solutions from global suppliers for your construction and mining projects.

- You receive consistent quality through certified products and documented test reports.

- Expert support from trusted brands like Novafit enhances safety and operational efficiency.

- You minimize downtime and service costs by choosing reliable Hose and Fitting Supply partners.

| Key Factor | Description |

|---|---|

| Certifications | ISO 9001, ISO 14001, and CE ensure product quality and safety. |

| Service | Responsive support for all construction equipment needs. |

Contact a global supplier today to secure high-quality hydraulic solutions for your next project.

FAQ

What is the main advantage of using a Custom Hose Assembly for construction equipment?

You gain precise fit and enhanced reliability. Custom Hose Assembly solutions match your equipment’s specifications, reduce downtime, and improve safety. You ensure optimal performance for excavators, loaders, and drilling machines.

How do I choose the right Hose and Fitting Supply partner?

You should select a supplier with proven experience, certified products, and strong after-sales support. Trusted brands offer quality assurance, fast delivery, and technical expertise for your hydraulic systems.

How often should I replace hydraulic hoses in mining equipment?

You should inspect hoses regularly and replace them every two to three years. Harsh environments may require more frequent changes. Early replacement prevents leaks and protects your equipment.

What testing procedures confirm hose reliability?

You benefit from burst pressure, impulse, and leakage testing. These procedures verify that your Custom Hose Assembly meets safety standards and performs under demanding conditions.

Can I get support for installation and maintenance?

You receive expert guidance from Hose and Fitting Supply specialists. They help with installation, preventive maintenance, and troubleshooting to keep your hydraulic systems running efficiently.