How to Evaluate Value vs. Price from a New Hydraulic Hose Fitting Manufacturer?

Table of Contents

You face a real challenge when evaluating value versus price from a new hydraulic hose fitting manufacturer. Price alone does not guarantee the best outcome for your operation. You need to look beyond the cheapest offer and consider long-term quality, reliability, and total cost of ownership. A structured evaluation process helps you avoid costly mistakes and ensures you select a partner who meets your technical and budget requirements.

What Makes a Hydraulic Hose Fitting Manufacturer Worth Your Investment?

- Evaluate both value and price when choosing hydraulic fittings. Focus on long-term benefits, not just upfront costs.

- Prioritize quality over price. High-quality fittings reduce leaks and downtime, saving money in the long run.

- Consider the total cost of ownership. Include installation, maintenance, and replacement costs in your evaluation.

- Check for certifications and standards. Ensure the manufacturer meets industry requirements for safety and reliability.

- Assess manufacturer support. Strong after-sales service can enhance product performance and reduce operational disruptions.

Understanding Value in Hydraulic Hose Fittings

Defining Value vs. Price

When you start to evaluate value vs. price from a New Hydraulic Hose Fitting Manufacturer, you need to understand what each term means for your operation. Price is the amount you pay upfront for hydraulic fittings. Value goes beyond the initial cost. It includes the performance, durability, and reliability you receive over time. If you focus only on the cheapest vs. best hydraulic fittings, you may miss hidden costs that affect your budget and system efficiency.

Consider this procurement guide for hydraulic fittings:

- Value includes the lifespan of the fitting, the frequency of replacements, and the impact on your system’s uptime.

- Price is just one part of the equation.

- You should evaluate value vs. price by looking at the total cost of ownership, not just the sticker price.

Tip: Always compare the long-term benefits and risks before making a decision. A fitting with a higher price may deliver greater value through fewer failures and lower maintenance costs.

Why Quality Matters for Value

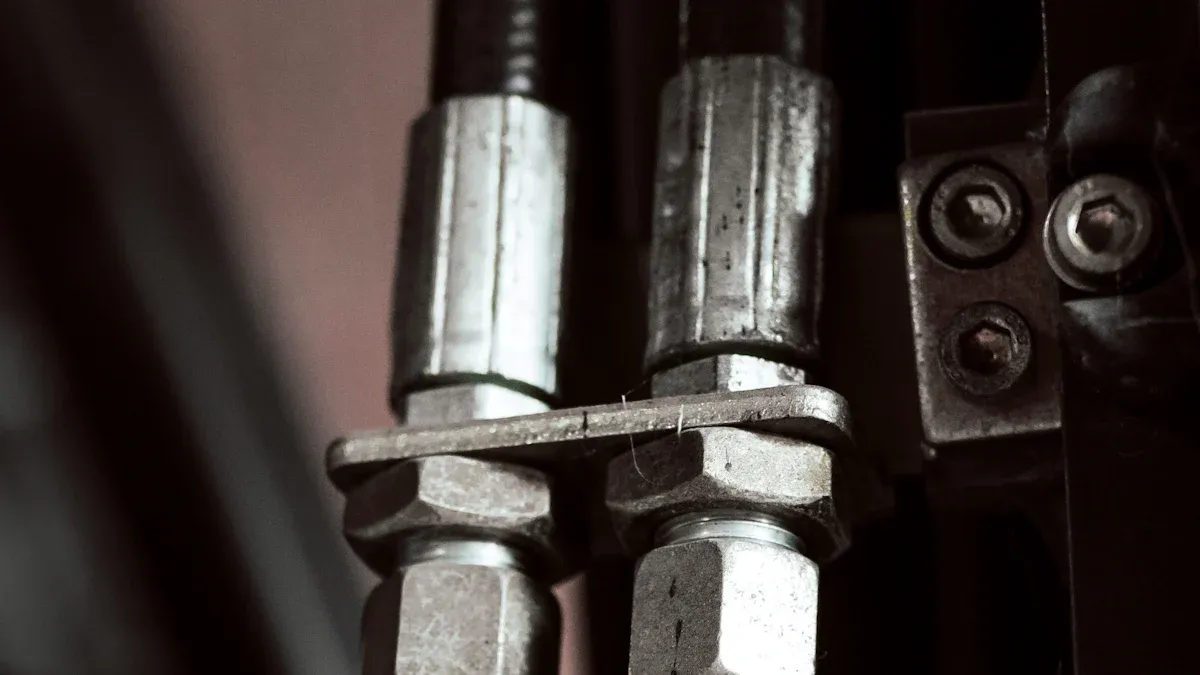

Quality is the foundation of value in hydraulic hose fittings. When you choose fittings with high quality, you protect your operation from leaks, breakdowns, and safety hazards. The integrity of hydraulic hose fittings is essential for operational safety and performance. High-quality fittings are designed to prevent leaks and withstand high pressures, which is critical in reducing the risk of accidents and system downtime. Proper selection and installation of these fittings ensure that they can handle the operational environment and fluid characteristics, thus maintaining the overall reliability of the hydraulic system.

You face budget pressure, but sacrificing quality for a lower price can lead to costly repairs and lost productivity. Reliable fittings from a reputable New Hydraulic Hose Fitting Manufacturer add value by minimizing downtime and extending equipment life. When you evaluate value vs. price, always prioritize quality to maximize your investment and safeguard your operation.

| Factor | Price Impact | Value Impact |

|---|---|---|

| Material | Low | High |

| Manufacturing Process | Medium | High |

| Certification | Low | High |

This table shows how different factors affect both price and value. Quality influences every aspect of value, making it a critical consideration in your procurement guide for hydraulic fittings.

Key Factors to Evaluate a Hydraulic Hose Fitting Manufacturer

Choosing a new hydraulic hose fitting manufacturer requires a thorough evaluation of several critical factors. You need to look beyond price and focus on the elements that impact performance, reliability, and long-term value. This section will guide you through the most important aspects to consider when you evaluate value vs. price and select the best partner for your operation.

Assessing Quality of Hydraulic Fittings

You should start by examining the quality of hydraulic fittings. Material selection plays a major role in both price and value. High-quality materials ensure durability and reliability, which directly affect the lifespan and safety of your hydraulic systems. The table below summarizes the most common materials used by a manufacturer of hydraulic hoses and their key properties:

| Material | Properties |

|---|---|

| Stainless Steel | High strength and corrosion resistance |

| Brass | Suitable for less demanding conditions |

| Monel | Necessary for extreme environments |

| Hastelloy | Ideal for harsh conditions |

| Steel | Commonly used for durability |

| Aluminum | Lightweight and resistant to corrosion |

When you assess a hydraulic hose fitting manufacturer, consider how the choice of material impacts both the initial price and the long-term value. Stainless steel and Monel offer superior reliability in tough environments, while brass and aluminum may suit less demanding applications. Always match the material to your system’s pressure, fluid type, and operating environment.

Size, pressure rating, and connection type also influence the quality of hydraulic fittings. A reputable manufacturer of hydraulic hoses will provide clear specifications and testing data for each product. You should request this information to ensure the fittings meet your operational requirements and deliver consistent performance.

Tip: Never compromise on material quality or proper sizing. These factors determine the durability and reliability of your hydraulic hose fittings.

Certifications and Standards

Certifications and adherence to industry standards are essential indicators of a manufacturer’s commitment to quality and safety. When you evaluate a new hydraulic hose fitting manufacturer, check for compliance with recognized standards. These certifications demonstrate that the manufacturer follows strict guidelines for design, manufacturing, and testing.

| Certification | Description |

|---|---|

| ISO 18752 | Focuses on requirements for hydraulic hose assemblies used in mobile and industrial applications. |

| SAE J517 | Defines minimum requirements for construction, pressure ratings, and performance of hydraulic hoses. |

| SAE 100R series | Ensures hoses have been tested according to the Society of Automotive Engineers’ standards. |

Manufacturing standards such as those from SAE and ISO set performance benchmarks for hydraulic components. They ensure consistent quality and safety across all products. Compliance with these standards is crucial for maintaining the integrity and durability of your hydraulic hose fittings. Non-compliance can lead to failures under pressure, resulting in costly downtime and repairs. Advancements in materials and engineering, driven by these standards, enhance the longevity and reliability of your hydraulic systems.

Note: Always verify that your hydraulic hose fitting manufacturer holds up-to-date certifications. This step protects your investment and ensures ongoing reliability.

Manufacturer Support and Service

Supplier support is a key factor in long-term satisfaction and operational success. Leading manufacturers offer a range of after-sales services that go beyond the initial purchase. You should evaluate the level of support provided by your chosen manufacturer of hydraulic hoses. Look for the following types of support:

- Technical support for installation and troubleshooting

- Training programs for your maintenance staff

- Fast delivery of spare parts and replacements

- Ongoing consultation for system upgrades

Supplier support ensures product quality and reliability throughout the lifecycle of your equipment. Effective maintenance and aftermarket services, such as quick availability of spare parts and technical support, are highly valued by customers. These services help you minimize downtime and maintain peak performance. Compliance with international safety and environmental standards also influences purchasing decisions and builds customer loyalty.

Callout: Strong manufacturer support can make the difference between a smooth operation and frequent disruptions. Choose a hydraulic hose fitting manufacturer that stands behind its products and offers comprehensive after-sales service.

When you balance price and value, remember that the cheapest vs. best hydraulic fittings debate often comes down to the level of support and reliability you receive. A procurement guide for hydraulic fittings should always include an assessment of supplier support, certifications, and material quality. By focusing on these key factors, you can confidently select a manufacturer that delivers both immediate and long-term value.

Comparing Costs: Upfront vs. Lifetime Value

When you evaluate value vs. price from a new hydraulic hose fitting manufacturer, you face a critical decision. Procurement teams often feel pressure to reduce costs, but the lowest price does not always deliver the best outcome. You need to balance upfront expenses with the long-term value that quality fittings provide. Understanding how hydraulic hoses are priced and what determines the price of hydraulic hoses will help you make informed choices that protect your operation and your budget.

Total Cost of Ownership

You should never judge hydraulic hose cost by the initial invoice alone. The total cost of ownership includes every expense you incur throughout the product’s lifecycle. This approach gives you a clearer picture of the real value behind each price tag.

Key factors that contribute to the total cost of ownership include:

- Initial investment costs

- Installation costs

- Maintenance and repair costs

- Durability and performance under harsh conditions

- Quality of hoses used

- Energy savings

- Reduced labor costs

- Lower inventory requirements

- Environmental impacts

- Long-term savings through reduced replacement frequency

When you ask, “How is hydraulic hose priced?” or “What determines the price of hydraulic hose?”, you must look beyond the sticker price. Premium fittings may cost more upfront, but they often deliver energy savings, require less labor for maintenance, and reduce the need for frequent replacements. These benefits lower your operational expenses over time.

Tip: Calculate the total cost of ownership before making a purchase. A higher initial price can lead to significant savings in maintenance, labor, and downtime.

You also need to consider the price of hydraulic hoses in relation to their expected lifespan. Durable fittings reduce the frequency of replacements, which means fewer disruptions and lower inventory requirements. This approach aligns with a smart procurement guide for hydraulic fittings, helping you avoid the trap of the cheapest vs. best hydraulic fittings debate.

Downtime and Maintenance Risks

Downtime is one of the most expensive risks you face when choosing hydraulic hose fittings. A failure can halt production, delay delivery, and cause significant financial losses. The true cost of downtime often exceeds the savings from selecting a lower-priced product.

The following table highlights the impact of hydraulic hose fitting failures in different industries:

| Industry | Average Downtime Cost | Downtime Hours per Month | Annual Productivity Loss |

|---|---|---|---|

| Forestry | $1,200 per hour | 10-15 hours | Over $130 million |

| Cost per Minute | $20 per minute |

You can see that even a short period of downtime can result in thousands of dollars in lost productivity. When you focus only on price, you risk frequent failures and higher maintenance costs.

The choice between premium and budget fittings has a direct impact on your maintenance risks:

| Aspect | Premium Fittings | Budget Fittings |

|---|---|---|

| Reliability | High reliability with advanced materials | Lower reliability, prone to failures |

| Longevity | Longer lifespan, fewer replacements | Shorter lifespan, frequent replacements |

| Maintenance Costs | Lower due to fewer breakdowns | Higher due to frequent failures |

| Total Cost of Ownership | Higher upfront cost, lower long-term cost | Lower upfront cost, higher long-term cost |

Premium fittings reduce maintenance costs because you spend less time and money on repairs. You also benefit from fewer breakdowns and less labor required for replacements. Budget fittings may seem attractive due to their low price, but they often lead to premature failure and higher replacement rates. Over time, these hidden costs can far exceed the initial savings.

Note: Investing in reliable fittings from a reputable new hydraulic hose fitting manufacturer can increase your return on investment. You gain peace of mind, knowing your system will run smoothly and your delivery schedules will stay on track.

When you evaluate value vs. price, remember that the true cost includes both the visible and hidden expenses. Consider how hydraulic hoses are priced, what determines the price of hydraulic hoses, and how each decision affects your operation’s efficiency. By focusing on the total cost of ownership and minimizing downtime, you can make smarter procurement decisions that support your long-term goals.

How to Assess a New Manufacturer

Questions to Ask

When you evaluate a New Hydraulic Hose Fitting Manufacturer, you need to ask targeted questions to uncover their capabilities and reliability. These questions help you compare the cheapest vs. best hydraulic fittings and guide your sourcing decisions:

- Do you offer one- or two-piece hose fittings?

- Are your fittings compatible with the hoses you supply?

- Should I skive the hose for your fittings, or is it unnecessary?

- What fitting material do you recommend for my application?

- Can you provide bulk pricing options for mass production?

- How do you ensure timely delivery, especially during peak marketing activities?

- What customization options do you offer for specific market requirements?

- Which certifications do you hold for different regions?

- How responsive is your after-sales service team?

Tip: Asking these questions helps you prevent unexpected issues and cut downtime costs by selecting a manufacturer who meets your operational needs.

Data and Documentation to Request

Requesting the right documentation is essential for preventing potential leakage and ensuring product quality. You should ask for the following records before finalizing your procurement guide for hydraulic fittings:

| Type of Evidence | Description |

|---|---|

| Hydrostatic Pressure Testing | Confirms no leaks or deformation by applying 1.5 times the rated working pressure. |

| Leakage Testing | Assesses the adapter’s ability to retain fluid under real-world conditions. |

| Traceability Documentation | Includes steel mill certificates, seal information, and quality inspection reports for accountability. |

| Testing Records | Detailed records that verify the manufacturer’s commitment to quality and leak-free performance. |

- Always request detailed testing records.

- Ask for traceability documents to ensure accountability.

- Confirm that the manufacturer performs rigorous testing to guarantee quality and prevent leakage.

Verifying Quality Claims

You need to verify the manufacturer’s quality claims using third-party test results and certifications. Independent testing provides confidence that the fittings meet industry standards and perform reliably. The following table shows how third-party testing benefits different stakeholders:

| Stakeholder | Benefit of Third-Party Testing |

|---|---|

| Manufacturers | Ensures products meet standards and minimize liability. |

| Distributors | Maintains customer trust and satisfaction. |

| Designers | Confirms products meet performance criteria for specific applications. |

| Consultants | Supports analysis of product or installation failures. |

| Installers | Reduces errors and supports successful project results. |

| End Users | Offers peace of mind by confirming an independent evaluation for performance and safety. |

You should always verify that the manufacturer’s claims align with third-party results. This step helps you avoid sourcing products that may cause leakage and ensures you select fittings that cut downtime costs.

Practical Tips for Balancing Price and Value

Setting Evaluation Criteria

You face constant pressure to control costs, but you cannot ignore the risk that the cheapest hydraulic hose fittings may lead to poor performance and higher long-term expenses. To evaluate value vs. price from a New Hydraulic Hose Fitting Manufacturer, you need clear criteria that balance budget and reliability. Start by focusing on quality assurance, technical specifications, and total cost of ownership. These factors help you avoid costly mistakes and ensure your procurement guide for hydraulic fittings delivers results.

Consider the following criteria when you compare suppliers:

| Criteria | Description |

|---|---|

| Scalability | Can the solution grow with your operational needs? |

| Compliance | Does it meet current and upcoming regulatory standards? |

| Innovation | Are digital features or advanced materials incorporated? |

| Long-term ROI | Will the investment reduce downtime and maintenance costs? |

You should also prioritize certifications, traceability, and material compatibility. Quality certifications such as ISO 9001, ISO 14001, and ISO 45001 signal a supplier’s commitment to reliability. Always request material test reports, pressure test certificates, and dimensional inspection reports to verify claims.

Tip: Set your evaluation criteria before you start supplier discussions. This approach helps you compare the cheapest vs. best hydraulic fittings with confidence.

Building a Supplier Checklist

A structured checklist streamlines your vendor evaluation process and helps you balance price with value. You can use this checklist to assess each New Hydraulic Hose Fitting Manufacturer and avoid common procurement pain points.

| Checklist Item | Description |

|---|---|

| Supplier Experience | Evaluate supplier experience and track record in your industry. |

| Technical Expertise | Verify technical expertise and custom engineering capabilities. |

| Inventory Depth | Assess inventory depth and emergency response times. |

| Quality Certifications | Review quality certifications and testing procedures. |

| Customer Service | Examine customer service responsiveness and support systems. |

| Pricing Transparency | Compare pricing transparency and total cost of ownership. |

Follow these steps to improve your supplier selection outcomes:

- Verify certifications for hydraulic products.

- Review documented quality control processes.

- Request sample testing results for hydraulic fittings.

- Check warranty terms and compliance with hydraulic standards.

- Evaluate customer service and technical support responsiveness.

- Ensure transparent pricing and clear contract terms.

- Ask for references from other hydraulic users.

Note: A comprehensive checklist reduces risk and helps you select a supplier who delivers both immediate savings and long-term value.

By using these practical tips, you can confidently evaluate value vs. price, avoid the pitfalls of choosing the cheapest vs. best hydraulic fittings, and build a reliable procurement guide for hydraulic fittings.

You need to evaluate value vs. price when choosing a New Hydraulic Hose Fitting Manufacturer. Focusing only on the cheapest vs. best hydraulic fittings can lead to higher failure rates and costly downtime. The table below highlights the impact of premium versus standard components:

| Component Type | Initial Purchase Price | Failure Rate | Annual Downtime Cost | Annual Savings |

|---|---|---|---|---|

| Standard Components | Lower | 35-50% more failures | $172,800 | N/A |

| Premium Components | Higher | Significantly reduced | $112,320 | $60,480 |

You should use a procurement guide for hydraulic fittings that considers the total cost of ownership, supplier scorecards, and structured evaluation processes.

Tip: Build your supplier checklist with criteria like value, stability, communication, and technical support. This approach helps you secure reliable performance and long-term savings.

FAQ

What are the main factors affecting hydraulic hose prices?

You should consider material, size, pressure rating, and connection type. These factors affecting hydraulic hose prices impact both initial cost and long-term costs. Always evaluate value vs. price to avoid unexpected downtime and higher costs over time.

How much does it cost to replace a hydraulic hose?

Replacement costs depend on the hose type, fitting quality, and labor. You may pay more upfront for premium fittings, but you reduce downtime and maintenance costs. Always ask your New Hydraulic Hose Fitting Manufacturer for a detailed breakdown.

How can I minimize unplanned downtime with hydraulic hose fittings?

You can minimize unplanned downtime by choosing high-quality fittings, following a procurement guide for hydraulic fittings, and verifying supplier certifications. Reliable products cut downtime and lower costs, improving your operational reliability benefits and overall roi.

Why should I focus on total cost instead of just price?

Focusing on total cost helps you avoid the cheapest vs. best hydraulic fittings trap. You reduce unplanned downtime, lower maintenance costs, and improve roi. Always evaluate value vs. price for long-term savings and operational reliability.

What support should I expect from a New Hydraulic Hose Fitting Manufacturer?

You should expect technical support, fast delivery, and clear documentation. Strong support reduces downtime and costs. It also helps you evaluate value vs. price and ensures your procurement guide for hydraulic fittings delivers the best results.