How to Select a Hydraulic Adapter Manufacturer?

Table of Contents

When evaluating hydraulic adapter manufacturers, focus on quality certifications, compatibility, reliability, and strong after-sales support. Selecting the right hydraulic adapter manufacturer directly impacts system reliability and operational safety. Poor-quality adapters can cause leaks or equipment failure, leading to costly repairs and downtime. High-quality hydraulic adapters from a reliable hydraulic adapter supplier enhance system reliability, minimise maintenance, and ensure seamless fluid flow. Choosing a trusted name in fluid power solutions that leverages cutting-edge technology sets your operation apart. Leading hydraulic parts suppliers help you avoid expensive disruptions and provide confidence in every connection.

Key Factors to Consider When Evaluating Hydraulic Adapter Manufacturers for Your Industrial Applications

- Identify your specific application requirements to choose the right hydraulic adapters for your industry.

- Verify that manufacturers comply with essential quality certifications to ensure safety and reliability.

- Consider order volume and minimum order quantities to optimise costs and avoid excess inventory.

- Request product samples to assess quality and ensure they meet your technical specifications.

- Use a structured checklist to compare manufacturers and make informed decisions for your hydraulic needs.

Define Your Needs

Application Requirements

Before you select a hydraulic adapter manufacturer, you need to clarify your application requirements. Each industry has unique demands for hydraulic adapters. For example, construction equipment faces extreme vibrations and heavy loads, while agricultural machinery often requires quick-connect adapters for frequent changes. The table below summarises common requirements across major industries:

| Industry | Common Application Requirements |

|---|---|

| Construction Equipment | Connects cylinders, pumps, and motors; withstands extreme vibrations and loads. |

| Agricultural Machinery | Connects implements and hydraulic lines; quick-connect adapters for frequent attachment changes. |

| Aerospace and Defence | Must meet strict safety standards; used in landing gear, brakes, and steering systems. |

| Oil and Gas Industry | Handles extreme pressures and corrosive environments; stainless steel and weld-on adapters. |

| Automotive and Heavy Trucks | Used in hydraulic braking, steering, and suspension systems; SAE and metric adapters. |

| Marine and Offshore Engineering | Used in winches, cranes, and propulsion systems; stainless steel and nickel-plated adapters. |

Tip: Identify your system’s pressure, temperature, and environmental conditions to ensure you choose adapters that match your operational needs.

Standards and Certifications

You should always verify that your chosen manufacturer complies with essential international standards and certifications. This step guarantees safety, compatibility, and smooth customs clearance. Look for the following:

- ISO and SAE specifications for product design and performance.

- Local regulations on pressure ratings, thread types, and material grades.

- ISO 9001:2015 for quality management and ISO 14001:2015 for environmental management.

- IATF 16949 for disciplined manufacturing processes.

- ISO 8434-1 and SAE J514 for thread and port compatibility.

Note: Adapters that meet these standards perform reliably under demanding conditions and help you avoid costly compliance issues.

Order Volume

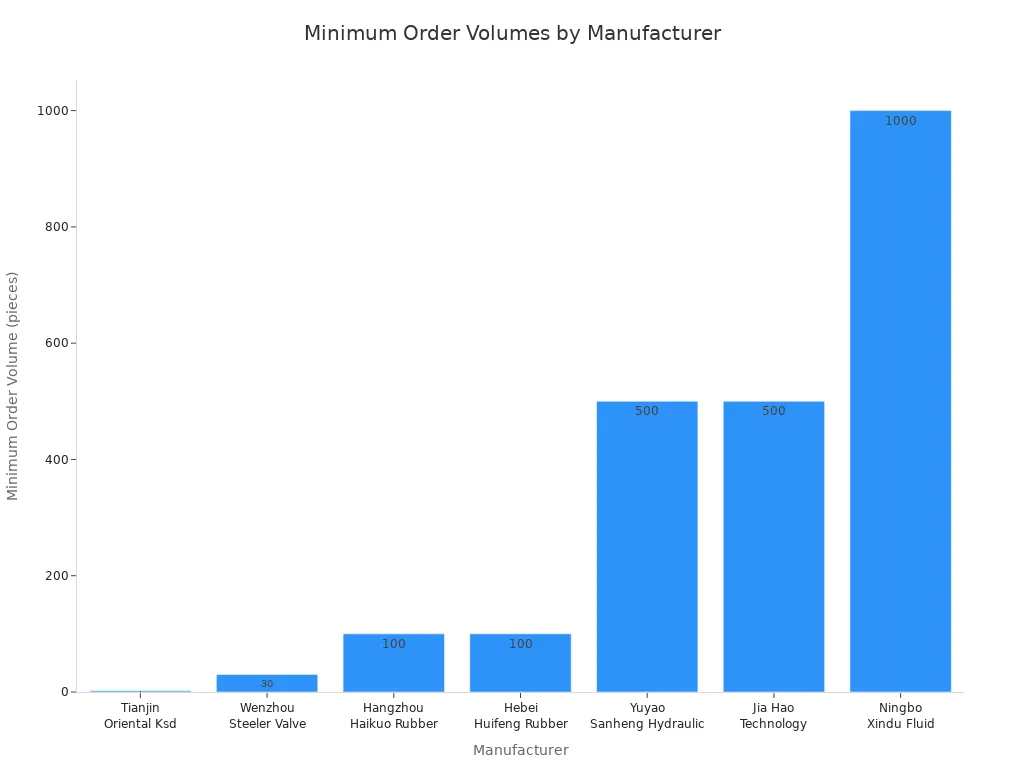

Order volume impacts your purchasing strategy and supplier selection. Leading manufacturers set different minimum order quantities (MOQs), which can affect your budget and inventory planning. Review the table below for a quick comparison:

| Manufacturer | Minimum Order Volume | Price Range |

|---|---|---|

| Wenzhou Steeler Valve Co., Ltd. | 30 pieces | N/A |

| Hangzhou Haikuo Rubber And Plastic Products | 100 pieces | $0.30-1.90 |

| Yuyao Sanheng Hydraulic Pipe Fitting Co., Ltd | 500 pieces | $1.50-2 |

| Jia Hao Technology Co., Ltd. | 500 pieces | $0.50-2.89 |

| Hebei Huifeng Rubber & Plastic Products | 100 pieces | $0.19-0.28 |

| Ningbo Xindu Fluid Technology Co., Ltd. | 1000 pieces | $0.23-0.29 |

| Tianjin Oriental Ksd Technology Development | 2 pieces | $5.43 |

You should match your expected order size with the manufacturer’s MOQ to optimise costs and avoid excess inventory.

Leading Hydraulic Adapter Manufacturers

Top Global Brands

When you evaluate hydraulic adapters manufacturer options, you should start with the most recognised names in the industry. These companies set the benchmark for quality, innovation, and reliability. Here are the top five global hydraulic adapter manufacturer brands by market share:

- AIR-WAY – Known for a broad product range and strong global presence.

- LAIKE – Delivers consistent quality and advanced manufacturing processes.

- Topa – Offers a wide selection of hydraulic adapters for diverse applications.

- UNISOURCE – Focuses on durability and custom solutions.

- BRENNAN – Renowned for precision engineering and robust supply chains.

You will also find other reputable hydraulic adapter manufacturers such as Parker, QMM, QC, HGW Hydraulic, Yuyao Tonghui, Gates, Eaton, RYCO, Manuli, StrongFlex, and Novafit Hydraulic. Each of these brands has earned a reputation for delivering reliable products and excellent customer support. Many leading hydraulic hose fittings manufacturers also produce adapters, ensuring compatibility across your hydraulic systems.

Choosing an established hydraulic adapter manufacturer gives you access to proven designs, certified materials, and global support networks. You reduce the risk of system failures and benefit from streamlined logistics. Leading hydraulic fittings manufacturers often provide technical expertise and after-sales service, which can be critical for complex projects.

Market Trends and Growth

The global hydraulic market continues to expand, driven by infrastructure development and industrial automation. You can expect the hydraulic adapter industry to grow at a compound annual growth rate (CAGR) of 5.4% from 2025 to 2035. The market size is projected to reach approximately 3,500 million USD by 2035, up from 1,951.2 million USD in 2024.

Key trends shaping the industry include:

- A strong focus on sustainability and eco-friendly materials.

- Integration of advanced technologies for improved performance.

- Increasing demand for custom and high-pressure solutions.

Asia Pacific stands out as the fastest-growing region, with a market size of around 0.5 billion USD in 2023 and a projected CAGR of 6.2%. As you select a hydraulic adapter manufacturer, consider those who invest in innovation and adapt to these trends. Top hydraulic fittings manufacturers and hydraulic fittings supplier brands often lead the way in adopting new technologies and sustainable practices, giving you a competitive edge.

Check Manufacturer Credentials

Quality Certifications

You should always verify the certification status of any reliable hydraulic adapter manufacturer before making a decision. Certification demonstrates a commitment to quality assurance and compliance with international standards. Leading hydraulic adapter manufacturers often display their certifications on their websites or product documentation. The table below highlights the most common types of certification you will encounter:

| Certification Type | Description |

|---|---|

| ISO Certifications | Indicate a manufacturer’s commitment to quality and adherence to internationally recognised standards. |

| Industry-Specific Standards | Ensure products are suitable for specific applications and environments, varying by sector. |

A manufacturer with multiple certifications signals strong quality and certification processes. This step helps you avoid costly compliance issues and ensures your adapters meet industry requirements.

Experience and Reputation

You gain significant advantages by choosing a reliable hydraulic adapter manufacturer with a long operational history. Manufacturers with decades of experience have built strong reputations through consistent performance and technological advancements. Consider these points when evaluating experience and reputation:

- Manufacturers with extensive operational histories have built strong reputations through accumulated experience.

- Technological advancements over the years have contributed to improved product quality and reliability.

- Long-term customer relationships foster trust and loyalty, enhancing the manufacturer’s reputation.

A well-established manufacturer often provides better quality assurance and more reliable support throughout your project.

Customer References

Customer references offer valuable insights into the strengths and weaknesses of a manufacturer. You should request references and review feedback on product performance, support, and delivery. Common strengths cited by customers include:

| Strengths | Description |

|---|---|

| Rigorous Quality Control | Ensures that each adapter meets required specifications and industry standards. |

| Advanced Manufacturing Capabilities | The manufacturer has the necessary resources and equipment to produce adapters that meet specific requirements. |

| Responsive Customer Support | Knowledgeable support team that addresses queries and provides guidance throughout the process. |

| Cost-Effectiveness | Competitive pricing without compromising quality, helping to save costs in the long run. |

You may also encounter feedback about the availability of specific adapters or the precision required in manufacturing. Always use customer references to confirm the manufacturer’s claims about quality and certification.

Assess Product Quality

Materials and Processes

You should always start by examining the materials and manufacturing processes behind hydraulic adapters. The right material selection directly impacts leak-free performance and long-term reliability. Manufacturers use several materials, each with unique benefits:

- Aluminium: Lightweight, boosts efficiency, and works well in high-performance applications.

- Steel: Offers strong corrosion and rust resistance, making it ideal for heavy-duty uses and high pressures.

- Stainless Steel: Delivers excellent cleanliness and suits sensitive environments due to its passivation process.

- Black Iron: Performs best in low to medium pressure systems and non-corrosive settings.

| Material Type | Corrosion Resistance | Weight Comparison | Cost Comparison |

|---|---|---|---|

| Stainless Steel | Excellent (marine-grade) | Heavier than aluminium | Higher cost than carbon steel |

| Aluminum | Good | Up to 1/3 lighter than steel | Cost-effective in certain applications |

| Carbon Steel | Moderate | Heavier than aluminium | Lower cost than stainless steel |

When you choose high-quality hydraulic connectors, you gain confidence in both durability and leak-free performance. Precision-engineered adapters, made from the right materials, help you avoid costly failures and downtime. If your application demands customised component solutions, ask about special alloys or coatings that can further enhance performance.

Testing and Traceability

You should never overlook testing when evaluating a hydraulic adapter manufacturer. Reputable suppliers use rigorous testing to guarantee leak-free performance and safety. Standard procedures include:

- Hydrostatic pressure testing, which applies 1.5 times the rated working pressure to confirm no leaks or deformation.

- Leakage testing, which checks the adapter’s ability to retain fluid under real-world conditions using static leak and volumetric loss tests.

Testing does not stop at the factory floor. Reliable manufacturers provide full traceability documentation. You receive steel mill certificates, seal information, and quality inspection reports with every batch. This traceability ensures accountability and simplifies future orders. When you demand thorough testing and documentation, you protect your system and ensure every adapter meets strict standards.

Tip: Always request detailed testing records and traceability documents before finalizing your order. This step helps you verify the manufacturer’s commitment to leak-free performance and quality.

Review Service and Support

Lead Times and Delivery

When you select a hydraulic adapter manufacturer, you need to consider how quickly they can deliver your order. Fast and reliable delivery keeps your projects on schedule and reduces costly downtime. Top manufacturers understand the importance of meeting deadlines. You can expect the following average lead times for custom hydraulic adapters:

- The industry standard lead time for custom hydraulic cylinders is usually 9 to 12 weeks.

- Some companies, such as Columbus Hydraulics, offer shorter lead times of 4 to 8 weeks, often delivering in as little as 4 to 6 weeks, including design time.

You should always ask about lead times before placing an order. Reliable delivery ensures you have the hydraulic hose connectors and hydraulic hose fittings you need, exactly when you need them. Delays can disrupt your workflow and increase expenses, so choose a manufacturer with a proven track record for on-time shipments.

Technical and After-Sales Support

Strong technical and after-sales support sets leading manufacturers apart. You benefit from expert guidance throughout the entire process, from design to installation and beyond. The best manufacturers offer a wide range of services to support your hydraulic hose connectors and hydraulic hose fittings needs:

| Service Type | Description |

|---|---|

| Design | Integration of design services for custom needs. |

| Measurement | Accurate measurement services for fittings. |

| Production | Manufacturing of hydraulic adapters. |

| Packaging | Professional packaging for safe delivery. |

| Delivery | Timely delivery of products. |

| After-sales service | Support and assistance post-purchase. |

You can also expect technical services such as new product design, CAD drawings, and expert technical advice. Responsive after-sales support helps you resolve issues quickly and ensures your hydraulic systems operate smoothly. When you choose a manufacturer with comprehensive support, you gain peace of mind and long-term value.

Compare Pricing and Value

Total Cost

You need to evaluate the total cost when selecting a hydraulic adapter manufacturer. The best hydraulic fittings suppliers often provide a clear breakdown of their pricing structures. Top brands may charge premium prices, but they offer unmatched support and availability. The table below compares leading manufacturers and their strategic pricing considerations:

| Manufacturer | Core Strengths | Strategic Considerations |

|---|---|---|

| Parker | Unparalleled availability and support | Premium brand with higher prices for smaller buyers |

| Brennan | Comprehensive source for hydraulic adapters | Manufacturer and distributor, ideal for diverse needs |

| Eaton | Dependable workhorse in fluid power | Broad range, reliable for maintenance across many sectors |

You should weigh the benefits of premium brands against your budget. Sometimes, the best hydraulic fittings cost more upfront but save you money through reduced downtime and better support.

MOQs and Discounts

Minimum order quantities (MOQs) and discount policies can impact your purchasing decision. The best hydraulic fittings manufacturers set different MOQs based on their production capabilities and market focus.

- Some manufacturers set MOQs as low as 50 pieces.

- Others may require MOQs of 500 or more units.

- Tiered discounts of 10–20% are often available for large orders.

- Smaller orders may incur a handling surcharge of 5–10%.

You should always confirm MOQs and ask about available discounts. This step helps you optimise your order size and maximise value from the best hydraulic fittings suppliers.

Customization Options

Customisation can set your project apart. Established manufacturers offer extensive product options and global service centres. They use advanced technologies to boost efficiency. Emerging manufacturers focus on flexibility and cost-effective solutions, tailoring products for specific project needs.

| Manufacturer Type | Customization Focus | Additional Features |

|---|---|---|

| Established Manufacturers | Extensive product options, global service centres | Advanced technologies for efficiency |

| Emerging Manufacturers | Flexibility in product customisation, cost-effective | Tailored solutions for specific project needs |

- Eaton invests in smart factories to improve production efficiency.

- Parker Hannifin delivers precision-engineered solutions for better performance.

- HGW Hydraulic offers cost-effective options for budget-conscious projects.

You should choose the best hydraulic fittings partner who matches your technical requirements and budget. Customisation ensures your hydraulic system performs at its peak.

Verify Compliance and Authenticity

Request Samples

You should always request product samples before committing to a large order. Samples allow you to inspect the hydraulic adapters firsthand and verify that they meet your technical requirements. When you receive a sample, check the material quality, thread compatibility, and overall finish. Reliable manufacturers, such as Novafit Hydraulic, provide samples that reflect their production standards. This step helps you confirm that the manufacturer can deliver consistent quality for your entire order.

To ensure compliance with international standards, follow these steps:

- Source from certified manufacturers. Work with suppliers who provide ISO, SAE, DIN, or JIS-certified hydraulic fittings.

- Conduct regular inspections. Perform routine checks to detect early signs of wear or failure in your adapters.

- Train your team on compliance. Educate employees about the importance of using standardised hydraulic components.

- Consult industry experts. Seek advice from hydraulic engineers or compliance specialists to ensure adherence to global standards.

Tip: Always ask for documentation that proves compliance with ISO or SAE standards. This documentation should accompany your samples and bulk orders.

Avoid Counterfeits

Counterfeit hydraulic adapters can compromise system safety and performance. You need to identify and avoid these fake products to protect your operations. Start by checking the packaging for inconsistencies with the manufacturer’s official branding. Inspect the documentation included in the package. Authentic products come with hard copies of manuals and certificates. Examine the packaging quality; genuine adapters use protective materials to prevent damage during shipping. Verify the presence of serial and model numbers on the parts or packaging. Their absence often signals a counterfeit. Inspect the raw materials for signs of poor quality, such as cracks or uneven finishes.

Engage with reputable hydraulic repair services and trusted suppliers. These professionals maintain reliable supply chains and prioritise authentic parts. Brands like Novafit Hydraulic have established reputations for delivering genuine, certified adapters. By following these steps, you ensure that your hydraulic systems remain safe, efficient, and compliant.

Choosing the Right Hydraulic Adapters Manufacturer

Use a Checklist

Selecting the right partner from the many hydraulic adapter manufacturers requires a structured approach. A detailed checklist helps you compare options and ensures you do not overlook critical factors. You can use the following table to guide your evaluation:

| Criteria | Description |

|---|---|

| Supplier Experience | Evaluate supplier experience and track record in your specific industry. |

| Technical Expertise | Verify technical expertise and custom engineering capabilities. |

| Inventory Depth | Assess inventory depth and emergency response times. |

| Quality Certifications | Review quality certifications and testing procedures. |

| Customer Service | Examine customer service responsiveness and support systems. |

| Pricing Transparency | Compare pricing transparency and total cost of ownership. |

You should also include these essential points in your checklist:

- Look for adapters tested according to ASTM B117 for corrosion resistance.

- Ensure compliance with SAE design criteria for optimal performance.

- Check for industry-specific certifications and quality management systems.

A checklist keeps your evaluation process organised. You can quickly identify which manufacturer meets your requirements for adapter quality, technical support, and delivery reliability. This approach reduces the risk of costly mistakes and helps you build a long-term partnership.

Tip: Print your checklist and use it during supplier meetings. Mark each criterion as you gather information. This method gives you a clear overview and supports confident decision-making.

Final Evaluation

After you complete your checklist, you need to conduct a final evaluation. This step ensures you consider every critical factor before making your selection. Use the table below to structure your assessment:

| Factor | Description |

|---|---|

| Quality Standards | Prioritise manufacturers with ISO certifications to ensure quality and reliability in hydraulic adapters. |

| Material Quality | Evaluate the materials and manufacturing processes used by manufacturers to guarantee durability and performance. |

| Pricing Structure | Understand the complete pricing structure, including potential hidden costs, to manage your budget effectively. |

| Manufacturer Reputation | Research customer reviews and testimonials to gain insights into the reliability and performance of manufacturers. |

| Customer Support | Evaluate the availability of technical support and guidance to ensure seamless operation of hydraulic systems. |

| Warranty Policies | Review warranty terms to understand coverage and conditions, indicating the manufacturer’s confidence in their products. |

You should review each adapter sample for material quality, thread compatibility, and finish. Compare the results with your checklist. Reliable manufacturers provide clear documentation, transparent pricing, and responsive support. They also offer adapters that meet or exceed industry standards.

Do not overlook the importance of warranty policies. Strong warranties show that the manufacturer stands behind their adapters. You gain peace of mind knowing that your investment is protected.

When you complete your final evaluation, you can select a manufacturer with confidence. You ensure that every adapter in your system delivers the performance, safety, and reliability your operation demands.

Related Hydraulic Fittings Manufacturers

Fittings vs. Adapters

You often see hydraulic fittings and adapters used together in fluid power systems, but they serve different purposes. Fittings create secure connections between hoses, tubes, and major components like pumps or cylinders. Adapters, on the other hand, help you join components that have mismatched sizes or thread types. Understanding these differences helps you select the right part for your system and avoid compatibility issues.

Here is a quick comparison to clarify their roles:

| Feature | Hydraulic Fittings | Hydraulic Adapters |

|---|---|---|

| Primary Function | Connect hoses and tubes to major components in hydraulic systems | Connect different types of fittings to allow compatibility between mismatched components |

| Application | Used in pumps, valves, cylinders, and motors to ensure secure connections | Used to connect components with differing sizes or standards, such as metric hoses to BSPP fittings |

| Example Usage | Facilitate fluid flow without leaks, change direction or elevation of tubing lines | Allow connection of incompatible components, such as a female ORB cylinder to a JIC hose |

Tip: Always match fittings and adapters to your system’s pressure and compatibility requirements to ensure leak-free performance.

Leading Fittings Brands

You have many choices when it comes to hydraulic fittings manufacturers. Leading brands offer a wide range of products, global support, and proven reliability. Here are some of the top names you should consider:

- MANULI: Delivers hydraulic hoses and fittings in 24 countries, known for innovation and quality.

- EATON: Offers a broad selection of hydraulic products and maintains a strong global presence.

- DANFOSS: Focuses on sustainability and provides a diverse hydraulic portfolio.

- SANNKE: Specialises in fittings and adapters, balancing quality with affordability.

- ALFA GOMMA: Brings over 70 years of experience in hydraulic hoses and fittings.

- F.O.R: Produces high-quality hydraulic components, including fittings and adapters.

- CAST: Supplies high-pressure hydraulic fittings and adapters worldwide.

- RASTELLI: Known for precision and quality in hydraulic fittings and adapters.

- Fluid Connectors by DOOWON: Offers specialised hydraulic fittings and hoses from South Korea.

- KOMAN: Manufactures fittings and adapters with international certifications.

- HANSA-FLEX: Has over 60 years of experience in hydraulic hoses and fittings.

- VOSS: Produces fittings and valves with a strong reputation for reliability.

- STAUFFER Glove and Safety: Recognised for high-quality hydraulic hoses and fittings.

- AIR-WAY: Brings extensive experience in manufacturing fittings and adapters in the US.

You can rely on these manufacturers for consistent quality, technical support, and a wide selection of hydraulic fittings to meet your system’s needs.

You can select the right hydraulic adapter manufacturer by focusing on these key steps:

- Match fittings to your application and check pressure, size, and material compatibility.

- Verify certifications and ask about after-sales support.

- Use a checklist to compare suppliers and avoid costly mistakes.

- Confirm claims with samples and documentation.

Brands like novafit hydraulic earn trust through precision, transparency, and responsive service. Apply these guidelines to your next supplier evaluation for reliable, leak-free performance.

FAQ

What certifications should you look for in a hydraulic adapter manufacturer?

You should look for ISO 9001, ISO 14001, and SAE or DIN compliance. These certifications show that the manufacturer meets global quality and safety standards.

How can you verify the authenticity of hydraulic adapters?

Check for serial numbers, request official documentation, and inspect packaging quality. You can also ask for samples and compare them to known genuine parts.

Why does material selection matter for hydraulic adapters?

Material choice affects corrosion resistance, strength, and compatibility. Stainless steel works best for harsh environments. Aluminium offers lightweight performance. Carbon steel provides cost-effective durability.

What is the typical lead time for custom hydraulic adapters?

Most manufacturers deliver custom adapters in 4 to 12 weeks. Lead times depend on order size, complexity, and the manufacturer’s production schedule.

How do you ensure compatibility between adapters and fittings?

Always match thread types, pressure ratings, and material specifications. Consult technical datasheets or ask the manufacturer’s support team for guidance.