Parker Hannifin vs Novafit hydraulic adapter quality

Table of Contents

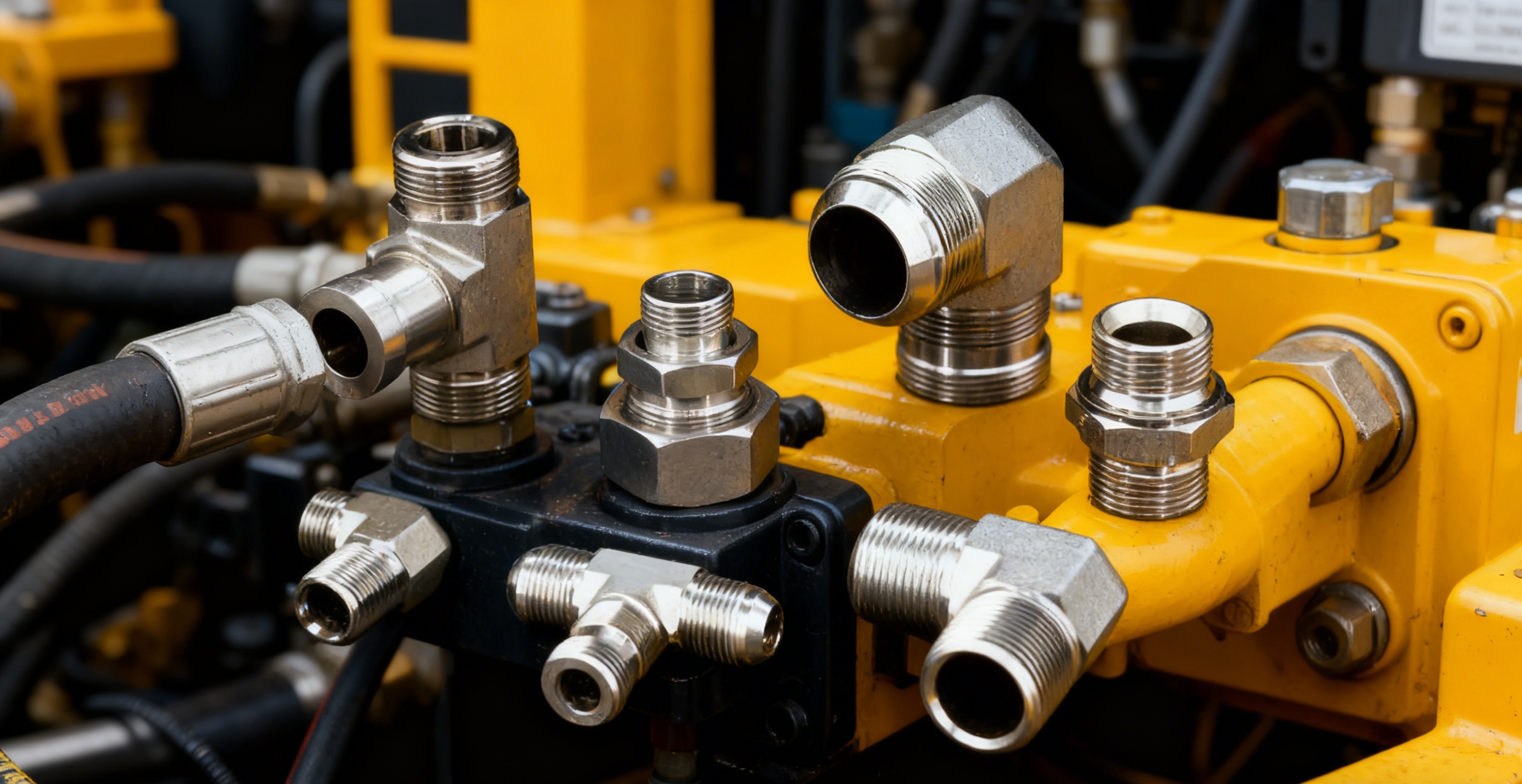

You often look for uncompromising quality when choosing hydraulic adapter manufacturers. Parker Hannifin stands out for its exceptional durability, reliability, and strict material standards. Novafit hydraulic adapter products also lead the industry through global innovation and advanced hydraulic system solutions. Market data shows Parker Hannifin holds an 18% global share, while Novafit claims 10%, reflecting their strong reputations:

| Company | Estimated Global Market Share |

|---|---|

| Parker Hannifin | 18% |

| Novafit | 10% |

Certifications, compatibility, and responsive after-sales support should guide your decision.

Why Novafit Hydraulic Adapter Solutions Stand Out in High-Performance Fluid Systems?

- Parker Hannifin is known for exceptional durability and reliability, making it a top choice for demanding applications.

- Novafit offers certified quality and innovative materials, providing cost-effective solutions for various industries.

- Evaluate pressure ratings and environmental resistance to ensure the right fit for your hydraulic systems.

- Both brands emphasise low maintenance needs, helping you save time and reduce operational costs.

- Always check for international certifications to ensure product quality and safety in your hydraulic applications.

Product Quality Overview

Parker Hannifin Quality

You expect Parker Hannifin to deliver product quality that sets industry benchmarks. The company’s reputation for precision-engineered hydraulic adapters comes from a strong commitment to research and development. Parker Hannifin invests in advanced technologies, which allows you to benefit from innovative solutions tailored to demanding hydraulic systems. Customers consistently rate Parker Hannifin’s product quality as superior, citing reliability and durability in both standard and extreme operating conditions.

Parker Hannifin’s reputation stands out among hydraulic Adapter manufacturers. You see their products used in aerospace, automotive, and heavy machinery sectors, where high-quality products are essential. The brand’s focus on meeting diverse industry needs ensures you receive adapters that perform consistently and maintain system integrity. When you choose Parker Hannifin, you invest in product quality that minimises downtime and maximises operational efficiency.

Tip: If you prioritize long-term reliability and proven performance, Parker Hannifin hydraulic adapters offer a strong value proposition.

Novafit Hydraulic Adapter Quality

Novafit hydraulic adapter products have gained recognition for advanced manufacturing processes and strict adherence to international standards. You notice their product quality through ISO 9001, ISO 14001, and CE certifications, which guarantee compliance and consistency. Novafit hydraulic adapter solutions use modern production techniques, resulting in high-quality products that meet the requirements of global industries.

Novafit hydraulic adapter quality reflects the brand’s commitment to innovation. You benefit from adapters designed for compatibility and ease of installation, which reduces maintenance time. Novafit hydraulic adapter products perform well in challenging environments, offering corrosion resistance and robust construction. The company’s reputation continues to grow as more customers experience reliable performance and responsive support.

| Brand | Product Quality Highlights | Reputation Strength |

|---|---|---|

| Parker Hannifin | Precision engineering, durability | Industry leader |

| Novafit hydraulic | Advanced manufacturing, certified | Rising global presence |

- Parker Hannifin leads the market with a reputation for innovation and reliability.

- Novafit hydraulic adapter products stand out for their certified product quality and modern manufacturing.

You can see that both Parker Hannifin and Novafit hydraulic adapter brands offer high-quality products, but their approaches differ. Parker Hannifin focuses on engineering excellence and broad industry application, while Novafit hydraulic adapter emphasises certification and manufacturing innovation. Your choice depends on whether you value established reputation and proven product quality or seek certified solutions with advanced features.

Material Quality & Build

High-Grade Materials

When you evaluate hydraulic hose fitting products, you notice Parker Hannifin uses a wide range of high-grade materials. You find aluminium, steel, stainless steel, and black iron in their adapters. Each material offers unique advantages for specific applications. Aluminium provides a lightweight solution for racing and high-performance machinery. Steel resists corrosion and handles high pressures in heavy-duty environments. Stainless steel ensures cleanliness and undergoes passivation for hygiene-critical uses. Black iron suits low-pressure hydraulic systems in non-corrosive settings.

| Material | Characteristics | Applications |

|---|---|---|

| Aluminum | Lightweight, ideal for high-performance applications | Racing, high-performance machinery |

| Steel | Corrosion and rust resistant, withstands high pressures | Heavy-duty applications |

| Stainless Steel | Cleanliness is crucial; undergoes passivation to remove foreign particles | Applications requiring hygiene |

| Black Iron | Used for low and medium-pressure systems, suitable for non-corrosive environments | Low-pressure hydraulic systems |

Novafit hydraulic Adapter manufacturers have introduced innovative material choices. You see poly alloy PEX and brass PEX in their hydraulic hose fitting products. Poly alloy PEX fights corrosion in acidic or basic environments and offers a lightweight, cost-effective option. Brass PEX delivers strength, heat resistance, and long-term durability. Novafit hydraulic also uses stainless steel and advanced synthetic fibres to improve quality and performance.

| Material | Advantages | Limitations |

|---|---|---|

| Poly Alloy PEX | Corrosion resistance, lightweight, safe, quiet | Less strength under stress, heat sensitivity |

| Brass PEX | Strong, heat-resistant, long-lasting, recyclable | Can corrode with some chemicals, heavier, costly |

Manufacturing Precision

You benefit from Parker Hannifin’s strict manufacturing standards. Their hydraulic hose fitting products meet ISO 9001, ISO 14001, OHSAS 18001, and IATF 16949 certifications. These standards guarantee consistent quality and safety. Novafit Hydraulic also follows ISO 9001 and ISO 14001, and operates a 40,000m² smart factory with over 2,000 CNC machines. You receive hydraulic hose fitting products with precise dimensions and reliable performance.

- Certifications include:

- ISO 9001: Quality management

- ISO 14001: Environmental management

- OHSAS 18001: Occupational health and safety

- IATF 16949: Automotive production quality

Longevity & Corrosion Resistance

You want hydraulic hose fitting products that last. Parker Hannifin’s use of stainless steel and specialised alloys ensures high durability and corrosion resistance. You experience fewer failures and reduced maintenance. Novafit hydraulic adapters use advanced chemical treatments and synthetic fibres to extend product life. Their brass and poly alloy PEX options resist corrosion and maintain quality in harsh environments. You gain confidence in the longevity of both brands, but Parker Hannifin’s reputation for durability stands out among hydraulic Adapter manufacturers.

Note: Choosing adapters with proven corrosion resistance and certified quality helps you minimize downtime and maximize system reliability.

Reliability & Performance

Pressure Ratings

You need hydraulic adapters that can handle high pressure without failure. Parker Hannifin designs adapters with industry-leading pressure ratings. You see their products tested to exceed standard requirements. This focus on pressure resistance gives you confidence in the reliability of your hydraulic system. Novafit hydraulic adapters also offer impressive pressure ratings. The company uses advanced materials and manufacturing to ensure adapters withstand demanding applications. You can trust both brands to deliver consistent performance under pressure.

When you compare Parker Hannifin and Novafit hydraulic, you notice both brands publish detailed pressure specifications. You find that Parker Hannifin often leads in maximum pressure ratings, especially in stainless steel and alloy adapters. Novafit hydraulic adapters match or exceed many industry standards, making them a strong choice for most applications. You should always check the pressure rating before installation to ensure system safety and reliability.

Tip: Always select adapters with pressure ratings that exceed your system’s maximum operating pressure. This practice improves reliability and prevents costly failures.

Performance in Harsh Environments

You often work in environments that challenge equipment. Extreme temperatures, corrosive fluids, and vibration can affect adapter performance. Parker Hannifin hydraulic adapters excel in harsh conditions. You benefit from their use of corrosion-resistant materials and advanced coatings. These features protect against rust and chemical attack, ensuring long-term reliability.

Novafit hydraulic adapters also perform well in tough environments. The company uses innovative materials like poly alloy PEX and brass PEX. These materials resist corrosion and maintain quality even in acidic or basic conditions. You see Novafit hydraulic adapters used in marine, chemical, and mining industries. Their adapters maintain performance and reliability when exposed to harsh elements.

You want adapters that prevent leaks and reduce maintenance. Parker Hannifin uses precision engineering to create tight seals. This design minimises the risk of leaks and extends the life of your hydraulic system. Novafit hydraulic adapters use advanced sealing technology to achieve similar results. You spend less time on repairs and more time on productive work.

| Brand | Pressure Ratings | Harsh Environment Performance | Leak Prevention |

|---|---|---|---|

| Parker Hannifin | Industry-leading | Excellent corrosion resistance | Precision seals |

| Novafit hydraulic | High | Innovative material solutions | Advanced seals |

Long-Term Reliability

You rely on your hydraulic adapters for continuous operation. Parker Hannifin builds adapters for long-term reliability. Their products undergo rigorous testing for fatigue, vibration, and thermal cycling. You see fewer failures and longer service intervals. This focus on reliability reduces downtime and lowers your total cost of ownership.

Novafit hydraulic also prioritises reliability. The company invests in research and development to improve adapter quality and performance. You benefit from adapters that maintain their integrity over time. Novafit hydraulic adapters offer reliable operation in demanding applications, giving you peace of mind.

You should consider maintenance requirements when choosing between brands. Parker Hannifin adapters require minimal maintenance due to their robust design. Novafit hydraulic adapters also offer low maintenance needs, thanks to their corrosion-resistant materials and advanced manufacturing. You save time and money by choosing adapters with proven reliability.

Note: Reliable adapters protect your entire hydraulic system. You avoid leaks, reduce maintenance, and extend equipment life by choosing products from trusted hydraulic Adapter manufacturers.

Key Takeaways:

- Parker Hannifin and Novafit both deliver high quality, reliability, and performance.

- You should evaluate pressure ratings, environmental resistance, and maintenance needs before making a decision.

- Reliable adapters ensure safe, efficient, and long-lasting hydraulic systems.

Quality Assurance & Certifications

International Standards Compliance

You want to trust the products you install in your hydraulic systems. Leading hydraulic Adapter manufacturers like Parker Hannifin and Novafit Hydraulic understand this need. Both brands comply with internationally recognised standards that set benchmarks for product quality and safety. You see Parker Hannifin adapters meeting ISO certifications, which confirm their commitment to consistent quality assurance. Novafit hydraulic adapters also fulfil specific ISO certifications, ensuring their products meet strict safety and performance requirements.

- ISO 9001: Quality management systems

- ISO 14001: Environmental management systems

- OHSAS 18001: Occupational health and safety management

- IATF 16949: Automotive production quality standards

These standards guide manufacturers to maintain high levels of quality assurance throughout production. You benefit from adapters that meet global expectations for reliability and safety.

Certification Impact

Certifications play a crucial role in quality assurance for hydraulic Adapter manufacturers. When you choose adapters certified to ISO and other international standards, you gain confidence in their performance and durability. These certifications show that Parker Hannifin and Novafit Hydraulic have invested in processes that guarantee quality at every stage.

Manufacturers who comply with these standards build trust and credibility in the market. You know that certified adapters meet safety and performance requirements, reducing the risk of system failures. ISO certifications reflect a manufacturer’s dedication to quality and consistency. You can rely on Parker Hannifin and Novafit Hydraulic to deliver adapters that meet high-quality benchmarks.

Tip: Always check for certifications before purchasing hydraulic adapters. Certified products offer better quality assurance and protect your investment.

You see that quality assurance is not just a promise—it’s a proven process backed by international standards. By choosing certified adapters, you ensure your hydraulic systems operate safely and efficiently.

Customer Feedback & Field Experience

Parker Hannifin User Reviews

You often hear positive feedback from users who rely on Parker Hannifin adapters in demanding environments. Customers report consistent performance and minimal downtime. Many users highlight the superior quality of Parker Hannifin products, especially in applications where reliability matters most. You see reviews that mention easy installation and strong seals that prevent leaks. Some users in the automotive and aerospace sectors praise Parker Hannifin for maintaining high standards among hydraulic Adapter manufacturers.

Common strengths reported:

- High durability in heavy-duty operations

- Reliable seals and leak prevention

- Consistent quality across product lines

Weaknesses occasionally mentioned:

- Higher upfront cost compared to competitors

- Limited availability in some regions

Novafit Hydraulic Adapter Reviews

Novafit hydraulic adapters receive praise for their innovative design and certified quality. You find users in the marine and chemical industries who appreciate the corrosion resistance and lightweight materials. Many reviews mention that Novafit hydraulic adapters simplify maintenance and reduce replacement frequency. Customers value the responsive support and global reach of Novafit hydraulic Adapter manufacturers.

Highlights from user feedback:

- Advanced materials improve corrosion resistance

- Certified quality meets international standards

- Quick installation and compatibility with various systems

Areas for improvement:

- Some users desire more options for high-pressure applications

- Occasional reports of longer lead times for custom orders

Case Studies

You can learn from real-world examples where Parker Hannifin and Novafit hydraulic adapters deliver results. In a mining operation, Parker Hannifin adapters reduced maintenance costs by 30% due to their robust quality and long service life. A chemical processing plant switched to Novafit hydraulic adapters and saw improved system reliability and fewer leaks, thanks to advanced materials and certified quality.

| Brand | Strengths | Weaknesses |

|---|---|---|

| Parker Hannifin | Durability, reliability | Higher cost, availability |

| Novafit hydraulic | Innovation, certifications | Pressure options, lead time |

Tip: You should always review customer feedback and field experience before choosing hydraulic Adapter manufacturers. Real-world results help you select adapters that deliver the quality your system demands.

Value for Money

Cost vs. Quality

You want to maximise your investment when selecting a hose fitting manufacturer for hydraulic solutions. Parker Hannifin often sets a higher price point, reflecting its commitment to quality and strict safety standards. Novafit hydraulic offers competitive pricing, making it attractive for budget-conscious buyers seeking reliable hydraulic solutions. You should weigh the initial cost against the proven durability and performance each manufacturer delivers. Many users find Parker Hannifin’s higher cost justified by its strong reputation for quality and long-lasting hydraulic hose fittings. Novafit hydraulic provides certified solutions that meet international safety standards, giving you confidence in their value.

| Manufacturer | Initial Cost | Quality Level | Safety Standards | Value Proposition |

|---|---|---|---|---|

| Parker Hannifin | High | Superior | Strict | Long-term reliability |

| novafit hydraulic | Moderate | High | Certified | Cost-effective solutions |

Tip: You should consider both upfront cost and expected lifespan when choosing a hose fitting manufacturer for hydraulic solutions.

Total Cost of Ownership

You need to look beyond the purchase price. The total cost of ownership includes maintenance, replacement frequency, and downtime. Parker Hannifin hydraulic hose fittings often require less maintenance due to their robust build and advanced engineering. You experience fewer failures, which reduces repair costs and system interruptions. Novafit hydraulic solutions also offer low maintenance, thanks to innovative materials and certified manufacturing processes. You benefit from adapters that maintain performance and minimise operational costs over time. Both manufacturers help you achieve reliable hydraulic solutions, but Parker Hannifin’s reputation for longevity can further reduce your long-term expenses.

ROI for Buyers

You want your investment in hydraulic hose fittings to deliver measurable returns. Parker Hannifin provides solutions that extend equipment life and improve system reliability. You see a strong ROI through reduced downtime and fewer replacements. Novafit hydraulic solutions deliver value by offering certified quality at a competitive price. You gain flexibility and compatibility across various hydraulic solutions, which enhances your operational efficiency. When you choose a hose fitting manufacturer with a strong reputation, you secure reliable hydraulic solutions that protect your investment and support your business growth.

Note: You should always evaluate ROI by considering quality, reliability, and total cost of ownership. Trusted hydraulic Adapter manufacturers like Parker Hannifin and novafit hydraulic help you achieve the best value for your hydraulic solutions.

- You maximise value by choosing a hose fitting manufacturer that delivers quality, safety standards, and reliable hydraulic solutions.

- Both Parker Hannifin and Novafit Hydraulic offer solutions that balance cost and performance, supporting your long-term investment in hydraulic hose fittings.

You gain the highest quality and reliability from Parker Hannifin, making it the superior choice among hydraulic Adapter manufacturers. You see this advantage in product durability, strict certifications, and strong customer feedback. Novafit hydraulic offers certified innovation and cost-effective solutions. When selecting a manufacturer, review the most important considerations:

| Consideration | Description |

|---|---|

| Quality Standards | High-quality adapters reduce maintenance and replacement costs, enhancing operational efficiency. |

| Pricing and Cost-Effectiveness | Transparent pricing structures help assess true costs. |

| Reputation and Reliability | Customer reviews and a proven track record indicate consistent performance. |

| Customer Support | Accessible technical support minimises downtime. |

- 🌱 Sustainability and digital transformation will shape future standards.

- 📈 Rigorous certifications like ISO 9001 and ISO 14001 will remain essential.

You should balance technical specifications with real-world results to ensure your hydraulic systems perform at their best.

FAQ

What makes Parker Hannifin and Novafit hydraulic adapters suitable for high-pressure hose applications?

You benefit from Parker Hannifin and Novafit hydraulic adapters because they meet strict performance requirements. Both brands design adapters for high-pressure hose systems. You see robust construction and advanced materials that withstand demanding hydraulic conditions.

How do certifications like ISO 9001 certification impact hydraulic adapter quality?

You gain confidence in the quality of hydraulic adapters when you choose products with certifications. Iso 9001 certification ensures consistent manufacturing standards. You see improved reliability and safety. Certifications help you meet industry regulations and performance requirements.

Can you use Novafit hydraulic adapters with high-performance hoses in harsh environments?

You can use Novafit hydraulic adapters with high-performance hoses in harsh environments. Novafit hydraulic Adapter manufacturers use corrosion-resistant materials. You see adapters that maintain integrity under extreme hydraulic conditions. Compatibility with high-pressure hose systems supports reliable operation.

What should you consider when selecting a flexible hose fitting manufacturer for hydraulic systems?

You should evaluate certifications, material quality, and compatibility. You can find flexible hose fitting manufacturers that offer high-pressure hose solutions. You benefit from brands with strong reputations among hydraulic Adapter manufacturers. Reliable support and proven performance requirements matter.

How do Parker Hannifin and Novafit hydraulic adapters compare in meeting performance requirements?

You see Parker Hannifin and Novafit hydraulic adapters tested for performance requirements. Both brands deliver adapters for high-pressure hose systems. You benefit from certifications and advanced engineering. You experience reliable hydraulic operation and reduced downtime.