Why OEMs in Italy and Sweden Prefer Customized Hose Fitting Solutions?

Table of Contents

You face growing demands for efficiency and compliance in your industry. OEMs in Italy and Sweden turn to custom hose fittings because your equipment must meet unique operational challenges and strict regulatory standards. Sustainability trends shape your decisions, pushing you to adopt reusable solutions that cut waste and lower maintenance costs.

| Factor | Impact on Your Operations |

|---|---|

| Sustainability Trends | Encourage reusable fittings to minimize material waste |

| Regulatory Frameworks | Require eco-friendly choices to meet legal standards |

| Custom Hose Fittings | Help you align with sustainability and compliance goals |

Trusted brands like NOVAFIT deliver reliable options that support your operational goals.

Hose Fittings Empower OEMs with Efficiency, Sustainability, and Reliable Performance

- Custom hose fittings help OEMs meet unique operational needs in industries like agriculture, manufacturing, and oil & gas.

- Sustainability is crucial; reusable hose fittings reduce waste and support environmental goals.

- Compliance with strict regulations prevents costly downtime and legal issues, making custom solutions essential.

- Reliable and safe hose systems reduce the risk of leaks and failures, ensuring smooth operations.

- Local manufacturing support and design adaptability enhance supply chain flexibility and speed up production.

Industry Needs and Compliance

Application-Specific Requirements

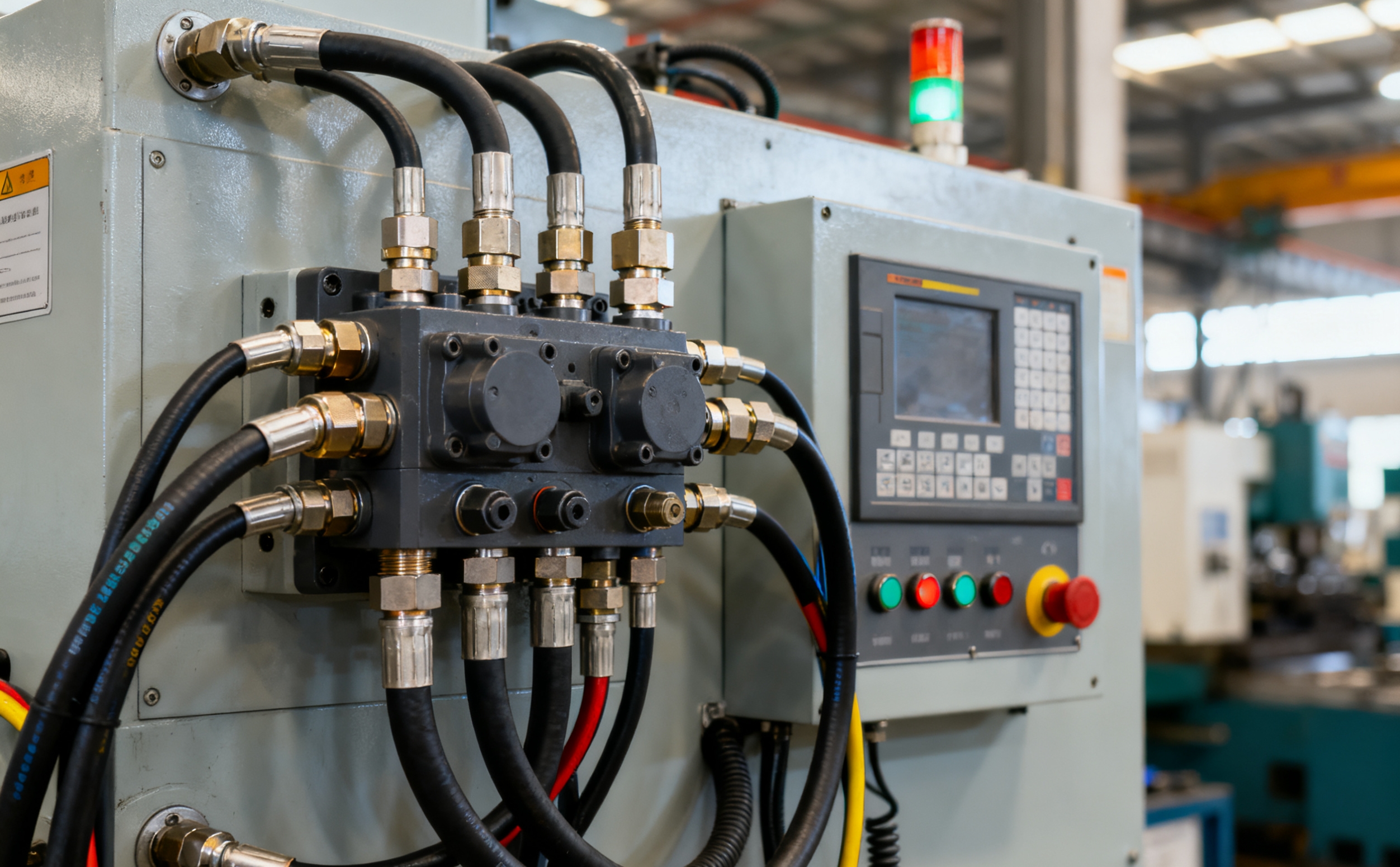

You operate in industries where every detail matters. In Italy and Sweden, you face unique operational environments that demand more than standard solutions. Agriculture, manufacturing, and oil & gas each present specific challenges for your equipment. You need hose systems that match your exact requirements for safety, efficiency, and durability.

| Industry | Application-specific Requirements | Influence on Demand for Customized Hose Fittings |

|---|---|---|

| Agriculture | Need for tailored solutions that meet operational challenges and safety standards. | Increased demand for fittings that ensure safety and efficiency. |

| Manufacturing | Focus on efficiency and reliability in equipment, requiring customized solutions. | Higher demand for fittings that optimize performance and reduce costs. |

| Oil & Gas | Strict safety standards and operational efficiency requirements necessitate specialized fittings. | Significant demand for customized solutions to meet these standards. |

You see how a single hose failure can disrupt your entire operation. In agriculture, you rely on hose assemblies that withstand harsh chemicals and fluctuating temperatures. In manufacturing, you need hydraulic fittings that maintain pressure and prevent leaks. Oil & gas applications require hose systems that meet the highest safety standards. Custom hose fittings give you the flexibility to address these needs directly. NOVAFIT supports you by designing solutions that fit your equipment and operational goals.

Regulatory and Sustainability Standards

You must comply with strict regulatory standards in both Italy and Sweden. These standards ensure your hose systems remain safe, reliable, and environmentally responsible. You cannot afford to overlook compliance, as non-compliance leads to costly downtime, legal penalties, and reputational damage.

| Standard | Description |

|---|---|

| ISO 8434 | Covers metallic tube fittings used in hydraulic systems. |

| ISO 4413 | Defines general rules for hydraulic fluid power systems, including safety. |

| ISO 12151 | Regulates hydraulic hose fittings for durability and pressure resistance. |

| SAE J514 | Governs flare-type tube fittings for high-pressure systems. |

| SAE J1926 | Ensures O-ring face seal fittings meet leak-prevention standards. |

| SAE J517 | Covers performance requirements for hydraulic hoses. |

| DIN 2353 | Regulates compression fittings for hydraulic applications. |

| DIN EN 853 | Defines performance standards for hydraulic hoses. |

| JIS B8363 | Covers metric hydraulic fittings used in Japanese industrial machinery. |

- Workplace accidents: Hydraulic failures can cause severe injuries or fatalities.

- Increased maintenance costs: Inferior fittings require frequent replacements, increasing downtime.

- Operational disruptions: Equipment failures due to faulty fittings can halt production lines.

- Legal liabilities: Companies may face lawsuits and regulatory fines for non-compliance.

In 2019, a manufacturing plant suffered a major system failure due to a non-compliant fitting rupture, resulting in a $2 million loss in production delays and legal fines.

You understand that sustainability is not just a trend. It is a requirement. You choose those solutions that reduce waste and support long-term environmental goals. NOVAFIT helps you meet these standards by offering custom hose fittings and hydraulic fittings that comply with international regulations and support your sustainability initiatives. You gain peace of mind knowing your hose systems meet both operational and legal expectations.

Custom Hose Fittings for Performance

Enhanced Reliability and Safety

You demand reliability and safety from every hose system in your operation. Custom hose fittings play a critical role in ensuring your equipment runs smoothly and safely. When you select fittings tailored to your machinery, you reduce the risk of leaks, bursts, and unexpected failures. NOVAFIT delivers solutions that match your specifications, helping you maintain a secure work environment.

End to end hose protection is a vital component in ensuring an overall secure and reliable work environment safeguarding both sensitive equipment, machinery, and of course, people. We recommend the Hose Connection Cover for hose couplings and connections to protect people working nearby if a coupling were to burst.

You benefit from advanced features such as traceability. This allows you to track every hydraulic fitting and hose throughout its lifecycle. You gain confidence knowing you can identify and resolve issues quickly.

Traceability helps trace (and retrace) the path of an item or part throughout its entire journey—from creation to end-use. Part traceability is critical for operations looking to ensure quality and safety.

NOVAFIT tests every hose and hydraulic fitting to rigorous standards. You receive products that pass inspection, lot testing, and in-press audits. This commitment to quality ensures your hydraulic hoses and high-pressure hoses perform under demanding conditions.

Our high-quality hoses are rigorously tested to every specification necessary, including receiving inspection, hose lot testing, in-press audits, and more.

Custom hose fittings improve compatibility with your equipment. You avoid mismatches that can lead to costly downtime. You also enhance durability, as each fitting is designed to withstand the pressures and environments specific to your application. Safety improves because you use hydraulic fittings that meet or exceed industry standards.

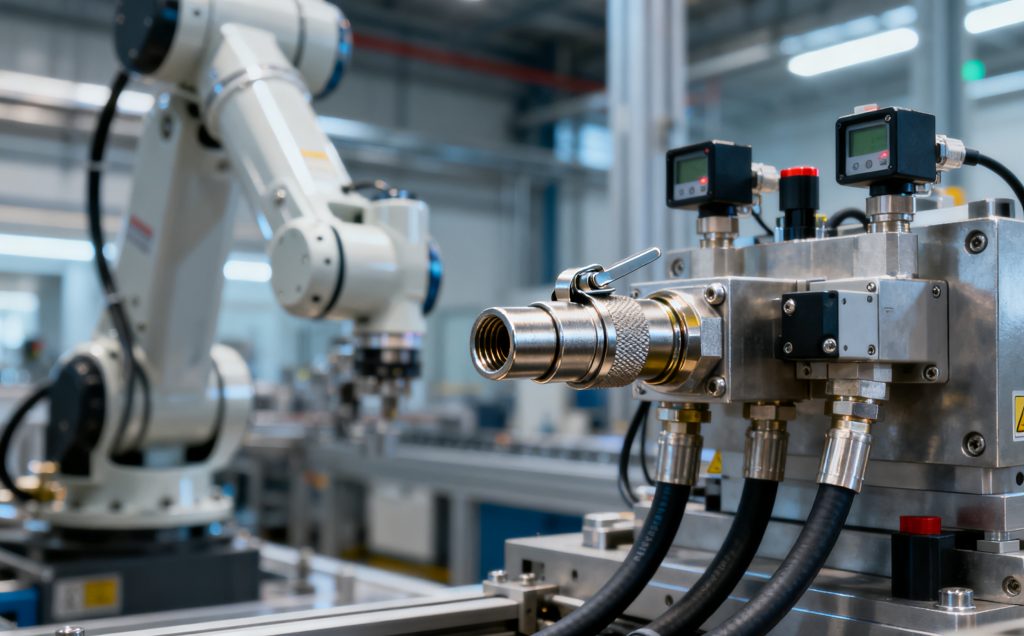

Hydraulic Hoses for Specialized Use

You operate in industries where standard solutions do not meet your needs. Custom hose fittings and hydraulic hoses allow you to address specialized requirements in agriculture, automotive, construction, and offshore drilling. NOVAFIT provides expertise in matching hydraulic hose types and fittings to your exact specifications.

| Application Type | Description |

|---|---|

| High-pressure spiral hoses | Used in jacking systems and offshore drilling. |

| Custom fittings for agriculture | Designed for agricultural machinery. |

| Custom fittings for automotive | High-tolerance brass fittings for brake systems. |

You rely on hydraulic hoses and fittings that perform in extreme conditions. High-pressure hoses support jacking systems and offshore drilling, where reliability is essential. Custom hydraulic fittings for agriculture withstand dust, moisture, and chemicals. Automotive applications require high-tolerance brass fittings for responsive braking. Construction projects depend on reinforced steel fittings that handle up to 10,000 PSI.

- Custom hydraulic fittings for irrigation systems that withstand dust and moisture.

- High-tolerance brass fittings for automotive brake systems ensure responsive braking.

- Reinforced steel fittings for construction hydraulics, capable of handling 10,000 PSI.

NOVAFIT understands your need for specialized hydraulic hose types. You receive solutions that fit your machinery and operational goals. Custom hose fittings and hydraulic hoses help you maximize performance, reduce maintenance, and improve safety across all applications.

Competitive Edge and Innovation

Faster Market Response

You operate in a market where speed matters. Custom hose fittings give you the ability to respond quickly to changing demands. Industries in Italy and Sweden require specialized solutions for hydraulic systems. You see manufacturers offering more customizable hose options to meet specific application needs, such as high-pressure environments and chemical resistance. This trend allows you to adapt your hydraulic equipment and hose assemblies to meet unique customer requirements and regulatory changes.

- You benefit from a growing selection of customizable hose and hydraulic fittings.

- You adjust your products rapidly to meet new safety standards or client specifications.

- You stay ahead of competitors by delivering solutions that match evolving market needs.

You know that a fast response can make the difference between winning and losing a contract. Custom hose fittings help you reduce lead times and streamline your production process. You avoid delays caused by waiting for standard hydraulic components that may not fit your application.

Product Differentiation

You need to stand out in a competitive market. Custom hose fittings enable you to offer unique solutions that set your products apart. On-site assembly of hydraulic hose systems increases your operational flexibility. You reduce inventory complexity by using field attachable fittings, which eliminates the need for a wide range of preassembled hose types.

- You provide clients with hose and hydraulic solutions tailored to their specific needs.

- You accelerate emergency repairs and accommodate last-minute design changes.

- You enhance your service capabilities by offering hose fittings that support customization for specialized hydraulic applications.

You improve your brand reputation by delivering reliable hydraulic hose systems that perform under demanding conditions. You attract customers who value innovation and flexibility. Custom hose fittings allow you to create products that meet the highest standards for hydraulic performance and safety.

Supply Chain Flexibility

Local Manufacturing Support

You need a supply chain that adapts to your production schedule. Custom hose fittings give you this flexibility. Local manufacturing support ensures you receive hydraulic hose assemblies quickly. You avoid long waits for overseas shipments. When you work with a trusted partner, you get preassembled hose lines that are ready to install. This approach improves process reliability and helps you meet strict quality standards. You can rely on just-in-sequence delivery, which means you receive each hydraulic hose component exactly when you need it. This method eliminates warehousing costs and keeps your operations lean.

| Solution | Key Benefits |

|---|---|

| Preassembled hose lines | Excellent process reliability and compliance with OEM quality standards. |

| Just-In-Sequence delivery | Quick adaptation to production needs and elimination of warehousing costs. |

| Mobile workshop solutions | Maximum availability of hydraulic hose lines and reduced downtime. |

Mobile workshop solutions also play a key role. You gain access to hydraulic hose lines on-site, which minimizes downtime. Your team can replace or repair a hose without waiting for external suppliers. This level of support keeps your equipment running and reduces unexpected costs.

Design Adaptability

You face changing requirements in your industry. Custom hydraulic hose fittings allow you to adapt designs quickly. You can modify hose assemblies to fit new machinery or update existing systems. This adaptability gives you a competitive edge. You respond to market changes faster than companies using standard hose solutions.

You also benefit from the ability to create hose assemblies that match your exact specifications. You avoid compatibility issues and ensure each hydraulic hose fits perfectly. This reduces installation time and prevents costly errors. When you need to scale production or introduce a new product, you can adjust your hydraulic hose designs without disrupting your supply chain.

Tip: Choose a supplier that offers flexible design services. This ensures your hydraulic hose solutions evolve with your business needs.

You stay ahead in your market by using custom hydraulic hose fittings that support both innovation and operational efficiency.

You gain a competitive advantage when you choose custom hose fittings. These solutions help you meet strict compliance standards, boost equipment performance, and drive innovation. NOVAFIT supports your goals with certified initiatives and sustainable practices.

| Initiative/Certification | Description |

|---|---|

| ISO 14001 | Responsible management of environmental impact |

| ISO 9001 | High product and service quality |

| SAF fuel investment | Reduced emissions from air travel |

| Solar panel installation | Enhanced renewable energy use |

| Employee satisfaction index | Improved workplace culture and performance |

You can achieve reliable operations and meet sustainability targets by customizing your hose systems.

FAQ

Why do OEMs in Europe prefer customized hose fittings?

You see, OEMs in Europe choose customized hose fittings because these solutions match specific operational needs. You gain better performance, improved safety, and easier compliance with local regulations. Customization helps you address unique challenges in agriculture, manufacturing, and oil & gas industries across Europe.

How do hydraulic hose fittings support sustainability in Europe?

You select hydraulic hose fittings that support sustainability by reducing waste and extending product life. In Europe, you find reusable hose fittings that help you meet strict environmental standards. You also lower maintenance costs and improve your company’s reputation for responsible operations.

What are the main benefits of using custom hose fittings in Europe?

You benefit from custom hose fittings in Europe by improving equipment compatibility and reliability. You avoid mismatches that cause downtime. You also meet regulatory requirements more easily. Custom solutions help you adapt quickly to market changes and maintain a competitive edge.

How does NOVAFIT ensure quality in hydraulic hose fittings for Europe?

You trust NOVAFIT because the company tests every hydraulic hose fitting to rigorous standards. You receive products that pass inspections and audits. NOVAFIT supports your operations in Europe by delivering reliable hose solutions that meet international certifications and local compliance needs.

Can you get local support for hydraulic hose assemblies in Europe?

You access local support for hydraulic hose assemblies throughout Europe. You receive preassembled hose lines quickly. Mobile workshops help you minimize downtime. You rely on just-in-sequence delivery to keep your supply chain flexible and your production schedule on track.