Industrial Adapter and Coupler Comparison for Optimized System Reliability

You have to make important choices when picking parts for your hydraulic systems. Choosing between an adapter and a coupler can decide if your connections stay tight and safe under pressure. In big industrial jobs, safety and working well depend on every small part. Novafit gives you advanced solutions for tough places. They make products with great care that help you get the best performance and keep your system strong.

Adapters and Couplers: Flexibility and Safety

- Adapters join parts that have different sizes or threads. This helps your hydraulic system stay flexible and easy to change.

- Couplers let you connect and disconnect parts quickly. They are good for systems that need a lot of maintenance or changes.

- Picking the right materials for adapters and couplers makes them last longer. It also helps them work well in places with high pressure.

- Always look at pressure ratings and make sure they fit your hydraulic system. This stops leaks and keeps everyone safe.

- Doing regular maintenance and installing couplers and adapters the right way can lower downtime and repair costs a lot.

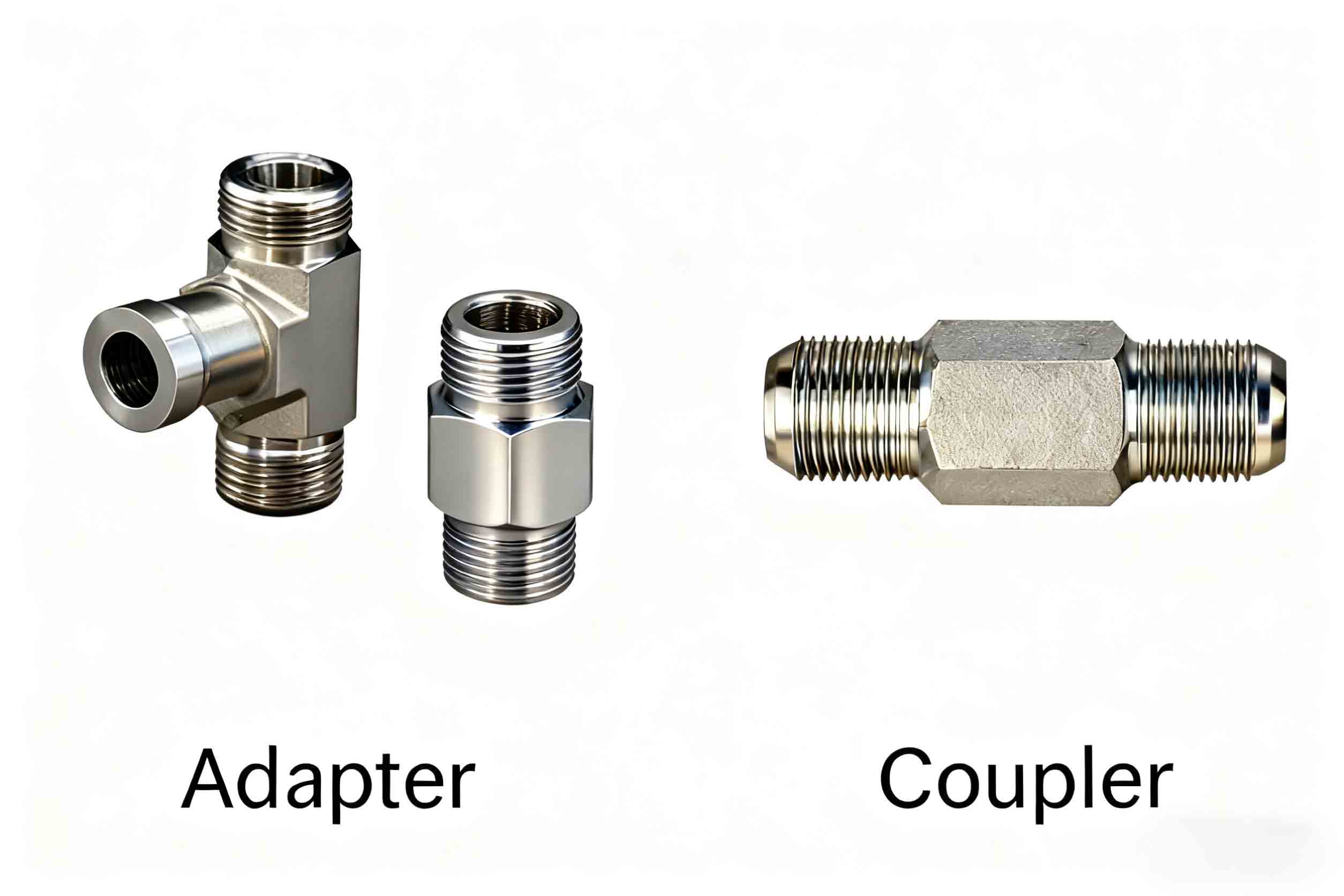

Adapter vs. Coupler

Adapter Definition

What Is an Adapter?

An adapter connects two parts that do not match. It helps join pipes, hoses, or equipment with different sizes or threads. Adapters make big systems more flexible and easy to change.

Primary Functions of Adapters

Adapters let you:

- Link pipes or hoses of different sizes.

- Join parts with different thread types.

- Change how a connection points or turns.

- Make it easy to swap parts in hydraulic systems.

You see adapters where rules for hydraulic connections are strict.

Typical Industrial Applications

Adapters are used in many places:

- Oil and gas plants

- Chemical factories

- Heavy machine assembly lines

- Power stations

Some types are:

- Grooved adapters

- Push-to-connect adapters

- Flare adapters

- Union adapters

- Elbow adapters

- Tee adapters

Key Differences from Couplers

Adapters and couplers both help connect things. They do not work the same way. The table shows how they are different:

| Feature | Coupling | Flange Adapter |

|---|---|---|

| Design | Tube-shaped, connects pipes directly | Flat, round edges, uses bolts |

| Components | Sleeve-style for tight seals | Flanges for extra strength |

| Installation Method | Holds by squeezing or mechanical force | Bolts and gaskets lock it in place |

| Size | Smaller and easy to fit | Bigger because of flanges |

| Purpose | Joins pipe ends smoothly | Connects pipes to other parts |

| Maintenance | Quick to set up, harder to reach | Easier to fix or change |

| Pressure Handling | Works for many pressures and temperatures | Made for high-pressure systems |

Coupler Definition

What Is a Coupler?

A coupler lets you connect or disconnect pipes, hoses, or tubes fast. You use couplers to make your system easy to change or fix. Couplers follow rules so they fit with many brands.

Main Functions of Couplers

Couplers help you:

- Connect or disconnect quickly and safely.

- Keep pressure steady when changing parts.

- Swap equipment easily.

- Meet the rules for hydraulic connections.

Common Use Cases in Industry

Couplers are used in:

- Pneumatic quick disconnect systems

- Hydraulic tool change stations

- Factory lines that change often

Some types are:

- Pneumatic quick disconnect couplings

- Pneumatic couplings

Rules like ISO 7241 and ISO 16028 set what hydraulic quick couplings must do. These rules help make sure couplers work well and fit with others.

| Standard | Description |

|---|---|

| ISO 7241 | Set size and basic needs for hydraulic quick couplings. Make sure they follow world rules. |

| ISO 16028 | Another rule for quick couplings. It checks if they fit and work well, like ISO 7241. |

Distinction from Adapters

Pick a coupler if you need to change connections often or fix things fast. Use an adapter when you need to join different sizes or threads for a long time. Couplers are for quick swaps. Adapters are for matching parts and making systems work together.

Tip: To keep your system strong, always pick parts that follow rules for swapping and hydraulic connections.

Hydraulic Adapter Couplings

Types

It is important to pick the right hydraulic adapter couplings. This helps your system work well every day. Novafit has many choices for you. You can pick straight, 45°, or 90° shapes. There are also tees, crosses, and reducers. Each shape helps with different connection problems in your system.

You can also choose from many thread standards. These are BSP, DIN, JIC, ORFS, and NPT. Each one is made for certain rules in the world. For example, BSP and NPT look alike but are not the same. They have different thread pitches and ways to seal. DIN fittings are very exact and used a lot in Europe and other places.

Here is a table that shows common adapter couplings and what they do:

| Type of Coupling | Description | Applications |

|---|---|---|

| Poppet Quick Couplings | Use a spring-loaded valve for secure sealing and reliable performance. | Agriculture, Oil & Gas, Industrial |

| Flat Face Couplers | Minimize fluid loss and prevent contamination with easy-to-clean surfaces. | Construction, Forestry |

| Threaded Flat Face Couplers | Offer mechanical strength with a threaded connection, ideal for heavy-duty applications. | Heavy-duty applications, Construction |

Note: Novafit adapter couplings follow strict rules. This means you can trust every connection.

Materials

You want your hydraulic system to be strong and last long. The material you pick for adapter couplings matters a lot. Novafit uses only the best materials for strength and long life.

| Material | Characteristics | Applications |

|---|---|---|

| Aluminum | Light and good for fast machines like race cars. | Racing and performance machinery |

| Steel | Does not rust and can handle high pressure. | Heavy-duty applications |

| Stainless Steel | Very clean and goes through special cleaning steps. | Places that need to stay very clean |

| Black Iron | Used for low and medium pressure. Good for places without much rust. | Low-pressure hydraulic systems |

Novafit adapter couplings are made with CNC machines for high accuracy. Heat treatment makes them harder and tougher. The sealing surfaces are made very well, so there are no leaks. This keeps your hydraulic system safe and working right.

Hydraulic Coupler Adapters

Design

When you pick hydraulic coupler adapters, you need to look at their design. Good design helps parts fit together and work well. These adapters connect different hydraulic parts. They are important in places where things must work all the time. You want adapters that can take high pressure. They should not break from shaking or moving. They must work with many fluids and temperatures. If the design is right, your system will be safe and work well, even when things get tough.

Here is a table that shows what matters most for hydraulic coupler adapter design:

| Design Consideration | Description |

|---|---|

| Material Selection | Pick materials that match pressure, temperature, and fluid type. Stainless steel is good for high pressure. Brass works for lower pressure. |

| Pressure Rating | The adapter should handle the highest pressure in your system. It must be rated above your top pressure. |

| Temperature Resistance | Needed for very hot or cold places. Nitrile and fluorocarbon O-rings help with high heat. |

| Vibration Resistance | Needed where things shake a lot. ORFS designs seal well and stays strong. |

| Application-Specific Design | Pick size, environment, and fluid type for the best fit. |

Tip: Always check pressure and temperature ratings before you put in hydraulic coupler adapters for quick couplings or quick-release coupling systems.

Integration

Hydraulic coupler adapters help your system work better and last longer. They make it easy to add new parts or grow your system. You do not need big changes. These adapters give tight connections. This stops leaks and keeps pressure steady. Your machines can run without problems.

- Hydraulic coupler adapters make tight connections. This means fewer leaks and less lost pressure.

- They make it easy to add or change parts in your hydraulic system.

- Good materials and things like O-ring seals and locks help fluids move well.

- You can use hydraulic coupler adapters with quick couplings. This makes fixing things faster and cuts down on waiting time.

If you pick the right hydraulic coupler adapters, your hydraulic systems will work well for a long time, even in hard jobs.

Reliability

Performance

Enhanced System Reliability

You need strong connections in your hydraulic systems. This helps your machines work well every day. Novafit makes adapters and couplers that work the same each time. You can trust these parts to keep your system safe. They help your machines run smoothly, even for long hours.

Leak Prevention through Advanced Sealing Technology

Leaks can stop your work or cause danger. Novafit uses special seals in every coupling. O-rings and tight seals keep fluids from leaking. Good materials and smart design help stop leaks. This protects your machines and keeps everything working right.

- Special seals and O-rings stop fluid leaks.

- Good design and strong materials help your system work better and leak less.

Performance in High-Pressure Environments

Hydraulic systems often have high pressure. Novafit adapters and couplers can handle this pressure easily. Each coupling is made to stay strong and safe. You know your system can do hard jobs without problems.

Vibration and Pulse Resistance

Factories and plants have lots of shaking and pressure changes. Novafit couplers and adapters are built to resist these forces. Strong parts and tight seals keep connections secure. Your machines stay safe, even when working hard.

Consistency in Demanding Industrial Applications

You want parts that work the same every time. Novafit checks every adapter and coupler for quality. You get reliable performance in all jobs, from big machines to complex systems.

Maintenance

Ease of Installation and Replacement

Novafit couplers and adapters are easy to put in. The parts fit well and are simple to use. This makes changing them fast and saves time.

Preventive Maintenance Features

You can make your parts last longer by doing these things:

- Teach workers how to use couplers the right way.

- Check couplers every day.

- Use only parts that fit together.

- Put oil on moving parts often.

- Look for problems in the hydraulic system.

- Store couplers in the right place.

Extended Service Life

Novafit uses strong materials and careful craftsmanship. This means adapters and couplers last a long time. You do not need to replace them often.

Reduced Downtime and Maintenance Costs

Using good hydraulic fittings helps you save money and time. You can lower downtime and repair costs by up to 35%. Better parts mean fewer problems and more work done.

Application

When to Use an Adapter

You need an adapter if your hydraulic system has parts with different thread types or sizes. This often happens in big factories where machines come from many places. An adapter helps connect these parts and keeps the system safe. Using adapters helps you avoid expensive stops and keeps everything working. You can pick straight, 45°, or 90° shapes to fit your setup. You also need to choose the right thread standard, like BSP, DIN, JIC, ORFS, or NPT, so it matches your system.

Explore Novafit Adapters

Discover our high-performance hydraulic adapters designed for reliability and safety in your systems.

Common scenarios for using an adapter:

- Connecting hydraulic pumps to pipes with different threads

- Joining hoses of different sizes in a power station

- Adding new machines to an old hydraulic network

Tip: Always check pressure ratings and make sure the material works with your system before you put in an adapter.

When to Use a Coupler

You use a coupler when you need to connect or disconnect hydraulic lines fast and safely. Couplers are important when you do a lot of repairs or change equipment often. In big factories, couplers help you save time and work better. You use couplers for tool change stations, moving machines, and systems that need regular checks.

Typical applications for a coupler:

- Quickly connecting hydraulic tools in a factory

- Fast disconnection of lines when upgrading equipment

- Temporary connections for testing or cleaning hydraulic circuits

| Use Case | Adapter Needed | Coupler Needed |

|---|---|---|

| Permanent connection | ✔️ | |

| Frequent disconnection | ✔️ | |

| Bridging thread types | ✔️ | |

| Quick maintenance | ✔️ |

Note: For the best results, always pick couplers and adapters made for your hydraulic system.

Selection Guide

Requirements

Pressure Rating and System Compatibility

Always check the pressure rating before picking a part. The pressure rating shows the highest pressure the part can withstand. If you use a part with a lower rating, it might leak or break. System compatibility is also very important. The parts you pick must match your hydraulic system’s rules and specs. If you do not check this, your system might not work or could be unsafe.

Connection Type and Thread Standards

You must match the connection type and thread standards to your system. Different places and jobs use different thread types like BSP, DIN, JIC, ORFS, and NPT. If you mix these without the right fix, you can get leaks or break things. Always check the thread type on both the machine and the new part. This makes sure the fit is tight and safe.

Material Compatibility and Corrosion Resistance

Material compatibility helps your hydraulic system last longer. If you connect metals that do not go well together, they can rust. For example:

- If you join a copper tube to a steel pipe, water can make the steel rust faster.

- In HVAC systems, aluminum and copper joints can break in wet places unless you use a special coating.

You should always pick materials that do not rust and match the fluids and conditions in your system.

Environmental and Temperature Considerations

Factories can be tough places for parts. You must think about hot or cold temperatures, chemicals, and dirt. Pick parts that can handle these things. For example, use nitrile or fluorocarbon O-rings for hot places. Stainless steel is good where things can rust.

Space and Installation Constraints

You need to think about how much room you have to put in parts. Some hydraulic systems have small spaces. Pick parts that are the right shape and size for your setup. This helps you avoid problems when putting them in and makes fixing them easier.

Tip: Always check the most important things before you choose a part. The table below shows what you should look at:

| Parameter | Description |

|---|---|

| Connection and Disconnection | Different couplings change how easy and fast you can use them. |

| ISO Standards | Make sure parts from different brands work together. |

| Application Requirements | Includes pressure rating, flow rate, and if materials match. |

| Environmental Conditions | Parts must resist rust, heat, cold, and dirt. |

| Ease of Use | Some connection types are easier to use for certain jobs. |

You must pick the right connection for your hydraulic system. A coupler lets you change parts quickly. It also makes fixing things easier. This helps you stop downtime and keep your work safe. If you need a strong or permanent connection, Novafit has good solutions. These parts are made to last and work well. Look at what your system needs. Then choose the best part for safety and long use.

FAQ

What is the main difference between an adapter and a coupler?

An adapter joins parts that do not fit together. It connects things with different threads or sizes. A coupler lets you connect or disconnect parts quickly. Adapters make a connection that stays in place. Couplers help you change parts fast in hydraulic systems.

How do I choose the right thread standard for my hydraulic system?

First, look at your system’s details. Find out what thread type your equipment uses. It could be BSP, DIN, JIC, ORFS, or NPT. Pick the same thread type for your new parts. This helps stop leaks and keeps your system safe.

Can Novafit adapters handle high-pressure and vibration environments?

Novafit adapters work well under high pressure and shaking. They are made with careful CNC machines. They use special seals to stop leaks. These adapters stay strong in tough jobs.

What maintenance steps help extend the life of hydraulic couplers and adapters?

Tip: Check your connections often. Always use parts that fit together. Put oil on moving parts. Store your parts in a good place. Doing these things helps your parts last longer and keeps your system working.

Are Novafit products compatible with international standards?

| Standard | Compatibility |

|---|---|

| ISO | ✔️ |

| DIN | ✔️ |

| JIC | ✔️ |

| BSP | ✔️ |

| NPT | ✔️ |